Electric tricycle

A technology for electric tricycles and front wheels, applied in the field of electric vehicles, can solve problems such as wheel slippage, achieve the effects of reducing slippage, avoiding wear problems, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

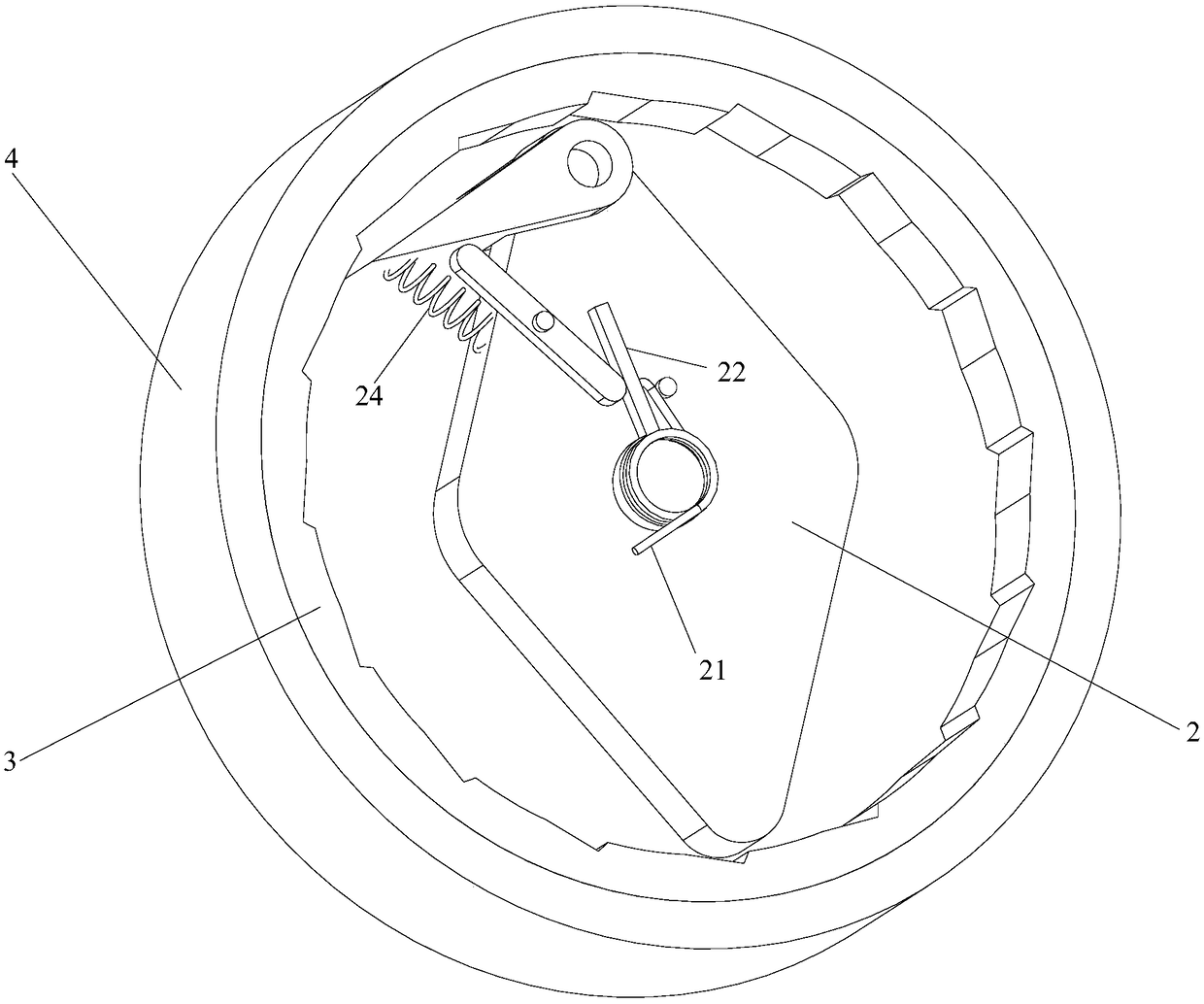

[0019] Embodiment 1: as Figure 1 to Figure 4 Shown, a kind of electric tricycle, comprises vehicle underframe and three wheels that are installed on described vehicle underframe, and described wheel comprises a front wheel and two rear wheels, and brake unit is arranged on the described front wheel, so The brake unit includes a main shaft 1, a chuck 3 rotatably arranged on the main shaft 1, and a buffer disc 4 rotatably arranged on the main shaft 1, and the buffer disc 4 is fixedly arranged with the front wheel, so The main shaft 1 is installed on the undercarriage, the main shaft 1 is fixed with a rhombus block 2, one end of the rhombic block 2 is provided with a rotatable block 25, and the corresponding chuck 3 is provided with a A number of slots 31 are evenly distributed along the circumferential direction, and a cylindrical spring 24 is fixedly arranged between the block 25 and the diamond-shaped block 2, and the cylindrical spring 24 is in a stretched state. A link mec...

Embodiment 2

[0025] Embodiment 2: On the basis of Embodiment 1, the rotation center of the second lever 23 can be placed on the side away from the main shaft 1, and a part of labor can be realized by using the difference in the moment arm.

Embodiment 3

[0026] Embodiment 3: On the basis of Embodiment 1 or Embodiment 2, the elasticity and the number of turns of the vortex spring 5 can be further set accordingly, and the shrinkage of the vortex spring 5 and the number of turns can be realized. The adjustment of the resistance generated by the wheels, and then control the deceleration time of the wheels and the braking distance, the application does not limit the specific elastic force and the number of turns of the spiral spring 5 here.

[0027] When not braking, the brake unit is in the initial state, that is, the vortex spring 5 does not shrink, the block 25 is in the second position, and the front wheel can rotate freely; when in use, the main shaft 1 is installed on the vehicle chassis, and the buffer disc 4 is connected to the front wheel. Fixed, the front wheel drives the buffer disc 4 to rotate together, and simultaneously through the vortex spring 5, the buffer disc 4 drives the chuck 3 to rotate ( image 3The middle ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com