Concrete mixing plant

A mixing station and concrete technology, applied in mixing plants, clay preparation equipment, mixing operation control, etc., can solve the problems of measuring and transportation time affecting the production efficiency of mixers, and achieve good dust removal effect, easy maintenance, and reasonable structural layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

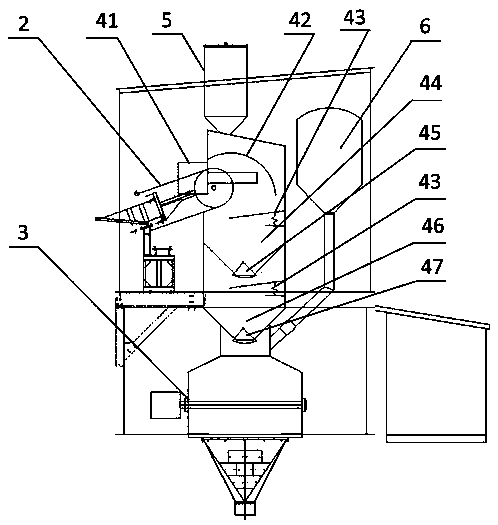

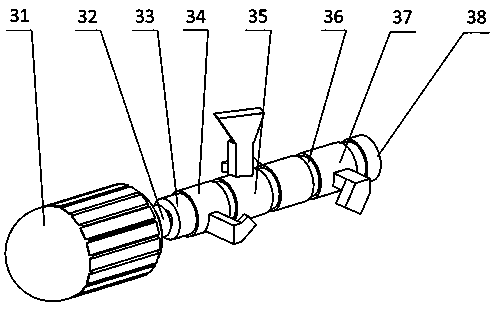

[0032] like Figure 1-3 As shown, a concrete mixing plant includes a gravel input station 1, a conveyor belt 2, a storage bin 4, a stirring device 3, a steel structure frame 7 and a control system box 8; the gravel input station 1 is located on the top of the conveyor belt 2 ; The conveyor belt 2 is connected to the side of the hopper 4; the stirring device 3 is installed below the hopper 4; the stirring device 3 is installed on the steel frame 7; the control system box 8 is located at The side of the stirring device 3; the described storage bin 4 is sequentially provided with an arc plate 42, a secondary storage hopper 44 and a primary storage hopper 46 from top to bottom; the primary storage hopper 46 and the secondary storage The first unloader 47 and the second unloader 45 are respectively provided at the bottom of the hopper 44; the outside of the hopper 4 is provided with a dust removal device; the first-level hopper 46 and the second-level hopper 44 are equidistant Arr...

Embodiment 2

[0044] like Figure 1-3 As shown, a concrete mixing plant includes a gravel input station 1, a conveyor belt 2, a storage bin 4, a stirring device 3, a steel structure frame 7 and a control system box 8; the gravel input station 1 is located on the top of the conveyor belt 2 ; The conveyor belt 2 is connected to the side of the hopper 4; the stirring device 3 is installed below the hopper 4; the stirring device 3 is installed on the steel frame 7; the control system box 8 is located at The side of the stirring device 3; the described storage bin 4 is sequentially provided with an arc plate 42, a secondary storage hopper 44 and a primary storage hopper 46 from top to bottom; the primary storage hopper 46 and the secondary storage The first unloader 47 and the second unloader 45 are respectively provided at the bottom of the hopper 44; the outside of the hopper 4 is provided with a dust removal device; the first-level hopper 46 and the second-level hopper 44 are equidistant Arr...

Embodiment 3

[0056] like Figure 1-3 As shown, a concrete mixing plant includes a gravel input station 1, a conveyor belt 2, a storage bin 4, a stirring device 3, a steel structure frame 7 and a control system box 8; the gravel input station 1 is located on the top of the conveyor belt 2 ; The conveyor belt 2 is connected to the side of the hopper 4; the stirring device 3 is installed below the hopper 4; the stirring device 3 is installed on the steel frame 7; the control system box 8 is located at The side of the stirring device 3; the described storage bin 4 is sequentially provided with an arc plate 42, a secondary storage hopper 44 and a primary storage hopper 46 from top to bottom; the primary storage hopper 46 and the secondary storage The first unloader 47 and the second unloader 45 are respectively provided at the bottom of the hopper 44; the outside of the hopper 4 is provided with a dust removal device; the first-level hopper 46 and the second-level hopper 44 are equidistant Arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com