Multifunctional inspection robot

An inspection robot and multi-functional technology, applied in the field of robotics, can solve the problems that the detection device cannot adapt to the inspected equipment, and the efficiency and accuracy of the inspected equipment are low, so as to ensure stability, improve efficiency and accuracy, and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

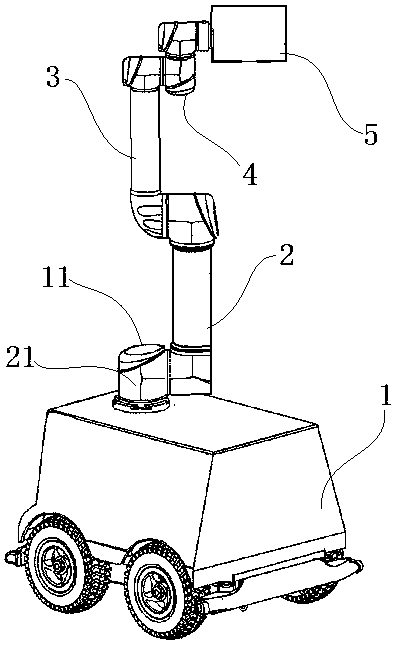

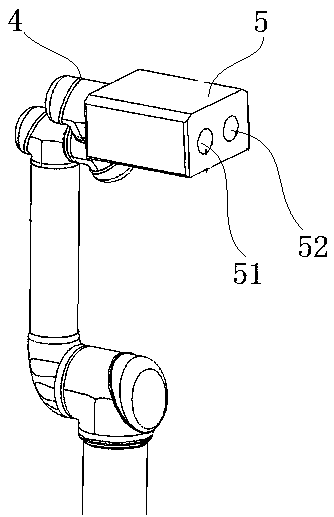

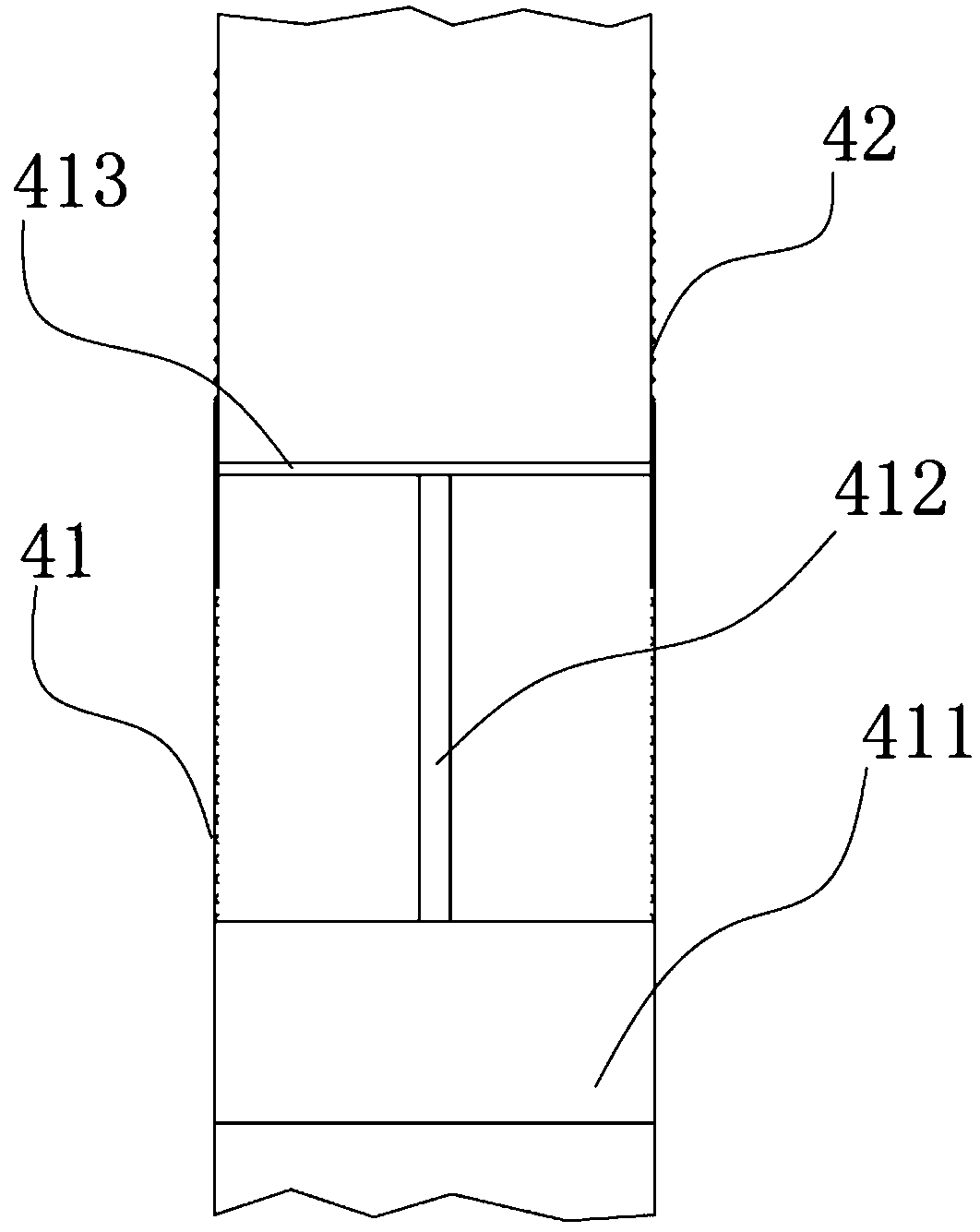

[0024] Such as figure 1 As shown, the present invention provides a multifunctional inspection robot, including a car body 1 and a mechanical arm arranged on the car body 1, the mechanical arm is provided with a first mechanical arm 2 connected to the car body 1, and the first mechanical arm A connecting piece 21 is provided on the arm 2 , and the connecting piece 21 can be connected with the connecting shaft 11 provided on the vehicle body 1 . The connection between the connecting piece 21 and the connecting shaft 11 adopts a rotational connection, and the rotating connection adopts a bearing connection, which can realize the relative rotation between the connecting piece 21 and the connecting shaft 11, and realize the relative rotation of the first mechanical arm 2 relative to the connecting shaft 11. The rotation of car body 1. In this embodiment, the mechanical arm is provided with a second mechanical arm 3 that is rotationally connected to the first mechanical arm 2, and ...

Embodiment 2

[0029] This embodiment is similar to Embodiment 1, the difference is that in this embodiment, the mechanical device is provided with several sections, and the several sections of mechanical arms are connected to each other by means of rotational connection. The flexible adjustment of the position of the detector 5 is realized by mutual rotation of several mechanical arms.

[0030] In this embodiment, the car body 1 is provided with a rolling device, and the rolling device is a four-wheel mechanism, which can effectively drive the robot to move and improve the efficiency and accuracy of the robot's inspection.

Embodiment 3

[0032] This embodiment is similar to Embodiment 2, the difference is that in this embodiment, a clamping device is provided between the rotating arm 42 and the detector 5, and the detector 5 can be removed through the clamping device, and at the same time The device enables the mounting of other tools to the swivel arm 42, extending the functionality of the robot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com