Production technology of sim mobile phone card slot and prepared coating for mobile phone card slot

A production process and card slot technology, which is applied to the production process field of SIM mobile phone card slots, can solve the problems of large equipment investment, large equipment area, and high equipment maintenance costs, saving equipment area and reducing equipment maintenance costs. , The effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

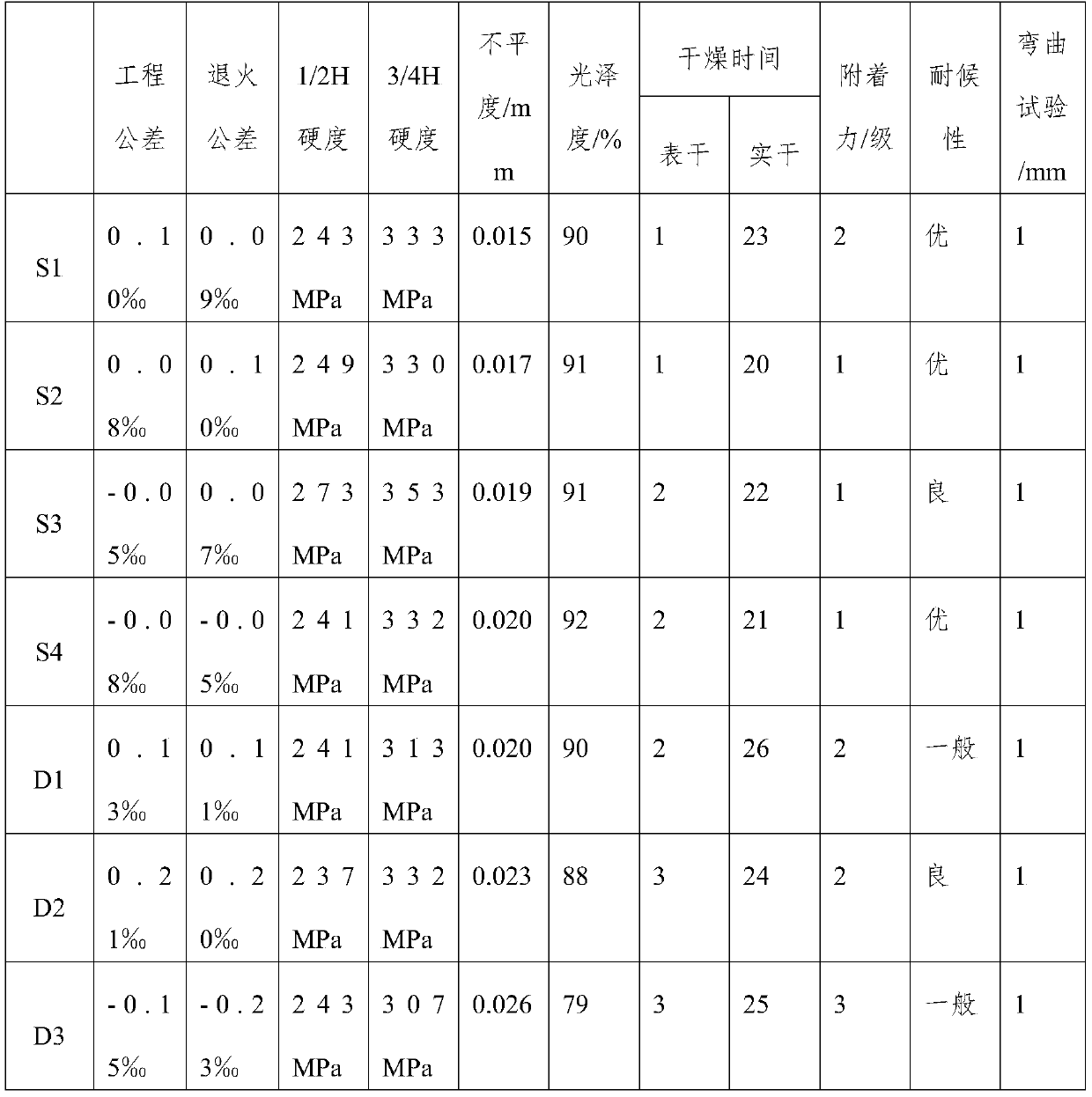

Examples

Embodiment 1

[0043] The present invention is the production process of SIM mobile phone card slot, including the following process steps: S1: draw production drawings according to the shape and size of the mobile phone card slot; select the stainless steel base material of the suitable size and material according to the size of the mobile phone card slot and determine the production Process steps, the production process steps include 7 steps; according to the shape and size of the mobile phone card slot to formulate the product production process size and draw the product deformation diagram;

[0044] S2: Draw up 7 production molds according to the product deformation diagram described in step S1;

[0045] S3: Load the first production mold into the continuous rolling mill, and after the base material enters the continuous rolling mill for rolling, the dimensions of the rolled base material are inspected;

[0046] S4: Anneal the material processed in step S3;

[0047] S5: Load the second productio...

Embodiment 2

[0057] The difference from the first embodiment is that the production process of the SIM mobile phone card slot includes the following sequential process steps:

[0058] S1: Draw production drawings according to the shape and size of the mobile phone card slot; select the stainless steel base material of suitable size and material according to the size of the mobile phone card slot and determine the production process steps. The production process steps include 7 steps; according to the mobile phone card slot Shape and size formulate product production process size and draw product deformation diagram;

[0059] S2: Draw up 7 production molds according to the product deformation diagram described in step S1;

[0060] S3: Load the first production mold into the continuous rolling mill, and after the base material enters the continuous rolling mill for rolling, the dimensions of the rolled base material are inspected;

[0061] S4: Anneal the material processed in step S3;

[0062] S5: Lo...

Embodiment 3

[0073] The only difference from the second embodiment is that the coating for the mobile phone card slot prepared by the production process of the SIM mobile phone card slot is composed of the following components by weight: 67.3 parts of DYS-637 resin, 0.8 parts of lubricant Wet dispersant BYK-P104S, 13.7 parts of titanium dioxide, 4.8 parts of phthalocyanine blue, 8 parts of barium sulfate, 0.2 parts of castor oil, 2 parts of organic bentonite, 0.2 parts of additives, 3 parts of diluent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com