A method and system for nanosecond pulsed laser lift-off of metal plate coatings

A nanosecond pulse laser and nanosecond pulse technology, which is applied in metal processing equipment, laser welding equipment, welding equipment, etc., can solve the problems of thermoforming processing substrate performance, influence, difficult to remove, etc., to achieve scientific and ingenious system design , broad application prospects, and the effect of improving stripping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

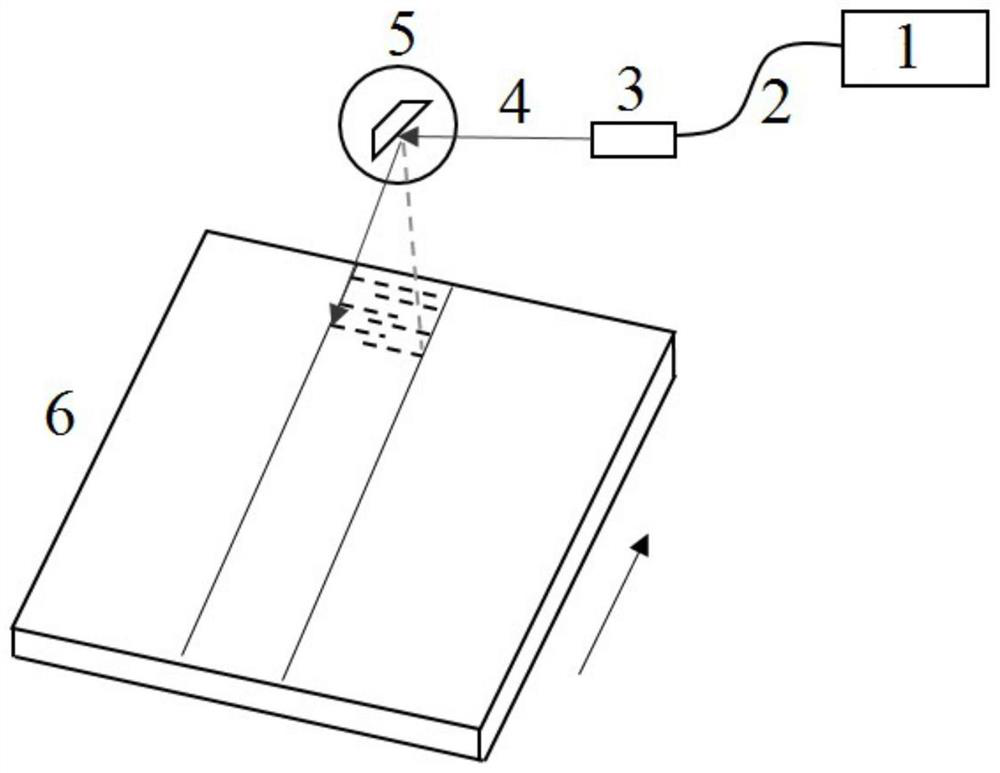

[0034] An embodiment of the present invention provides a method for performing nanosecond pulse laser stripping on a metal plate coating, specifically as figure 1 As shown, the laser beam 4 emitted by the nanosecond pulse laser 1 passes through the energy transmission fiber 2, the collimation head 3 and emits it to the surface of the coating to be stripped through the two-dimensional scanning galvanometer 5, and the coating to be stripped is passed through the nanosecond pulse laser After ablation, an explosive melting reaction occurs, and the metal plate is separated from the metal plate driven by the high-speed airflow generated on the coating surface.

[0035] At the same time, in order to remove the oxides generated after peeling off the coating, after the nanosecond pulse laser ablates the coating to be peeled off, adjust the frequency of the nanosecond pulse laser to quickly vaporize the oxides generated after peeling off the coating and detach from the metal plate .

...

Embodiment 2

[0043] An embodiment of the present invention provides a system for performing nanosecond pulse laser stripping on a metal plate coating, specifically as figure 1 As shown, it includes a nanosecond pulse laser 1, an energy transmission fiber 2, a collimation head 3 and a two-dimensional scanning galvanometer 5 arranged in sequence, and the laser beam 4 emitted by the nanosecond pulse laser 1 passes through the energy transmission fiber 2, the collimator The straight head 3 and the two-dimensional scanning galvanometer 4 emit to the surface of the metal plate coating to be stripped.

[0044] The nanosecond pulsed laser stripping metal plate coating system provided by the above embodiment has a scientific and ingenious design, a reasonable structure, wide practicability, and broad application prospects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com