Low-temperature cigarette inner film-coated cooling nozzle bar with film attached thereto

A technology for low-temperature cigarettes and inner coating, which is applied in the fields of tobacco, e-liquid filter elements, applications, etc. It can solve the problems of small contact area, difficulty in improving cooling efficiency, and difficulty in lengthening the gas path structure, and achieves a simple preparation method and no process required and equipment investment, production preparation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

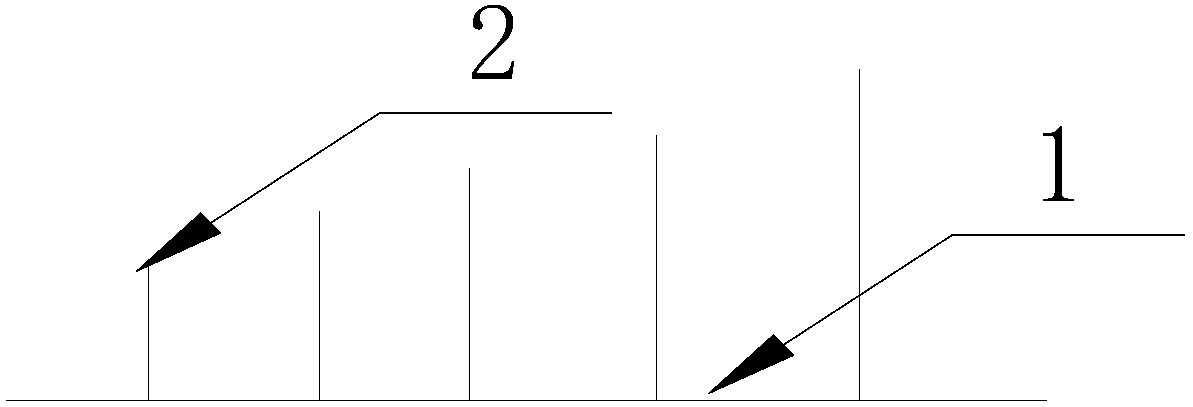

[0023] see figure 1 , a low-temperature cigarette inner-coated cooling mouth rod with a film attached, comprising a first hollow rod 3 connected to each other near the tobacco section, an inner film rod 4, an acetate rod 5, and a second hollow rod 6 near the mouth end, The diameter is 7.6mm, and the lengths are 14mm, 15mm, 6mm, and 6mm respectively. Wherein the hollow inner diameter of the first hollow rod 3 is 4 mm, and the hollow inner diameter of the second hollow rod 6 is 5 mm. The inner film rod 4 is made of three layers of acetate paper tape and two layers of polylactic acid cooling film 1, which are wound by a synchronous spiral process. The surface of the innermost polylactic acid cooling film 1 of the inner coating rod 4 is vertically loaded with a polylactic acid cooling film 2 with a thickness of 30 μm, and the cooling film 2 is arranged longitudinally on the cooling film 1, as shown in image 3 shown. The distance between two adjacent cooling films 2 is 2 mm, th...

Embodiment 2

[0027] see figure 1 , a low-temperature cigarette inner film-coated cooling mouth rod with a film, comprising a first hollow rod 3 connected to the tobacco section, an inner film rod 4, an acetate rod 5, and a second hollow rod 6 near the mouth end. The diameter is 7.6mm, and the lengths are 14mm, 15mm, 6mm, and 6mm respectively. Wherein the hollow inner diameter of the first hollow rod 3 is 4 mm, and the hollow inner diameter of the second hollow rod 6 is 5 mm. The inner film rod 4 is made of three layers of acetate paper tape and three layers of polylactic acid cooling film, which are wound by a synchronous spiral process. The surface of the innermost polylactic acid cooling film 1 of the inner coating rod 4 is vertically loaded with a polylactic acid cooling film 2 with a thickness of 45 μm, and the cooling film 2 is arranged horizontally on the cooling film 1, as shown in image 3 shown. The distance between two adjacent cooling films 2 is 2 mm, the height of each layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com