TiN Thin Film Etching Method

A thin film, dry etching technology, applied in decorative arts, gaseous chemical plating, microstructure technology, etc., can solve problems such as hindering the etching of TiN thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

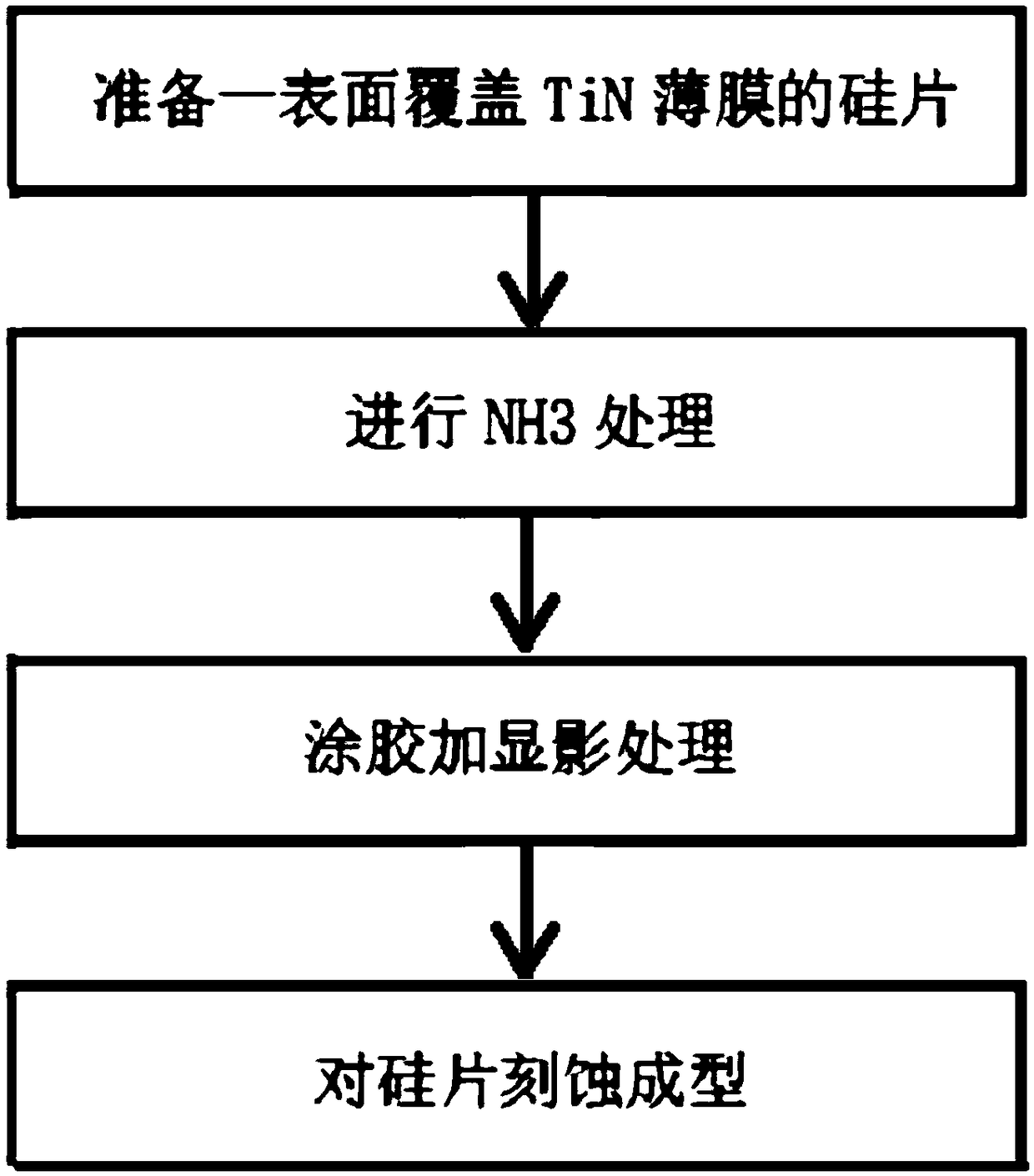

[0013] combine figure 1 As shown, the TiN thin film etching method is in the following examples, and the specific implementation process is as follows:

[0014] Step 1. Prepare a silicon substrate covered with a TiN thin film, that is, a silicon wafer covered with a TiN thin film. The thickness of the TiN thin film is 10-30 nm. The film-forming method of the TiN thin film is not limited to one of film-forming methods such as physical deposition (PVD) and chemical vapor deposition (CVD) or a mixed process method.

[0015] Step 2, performing NH3 treatment on the silicon wafer covered with TiN thin film. The equipment for NH3 treatment of silicon wafers covered with TiN film is CVD equipment process chamber or PVD equipment process chamber, the treatment process temperature is 250-400°C, the vacuum pressure is 3-10torr, the flow rate of NH3 is 30-100sccm, and the flow rate of N2 is 3 ~10k sccm, processing time is 10~30s.

[0016] Step 3, coating and developing the silicon waf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com