Automatic flexible assembling and calibration platform and method for meter-scale reflector

A reflector, meter-level technology, applied in installation, optics, instruments, etc., can solve the problems of uneven preload force of the reflector, influence of reflector stability, poor control of wavefront error, etc., and avoid cleanliness problems , Improve the quality and stability of installation and calibration, and the effect of uniform preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

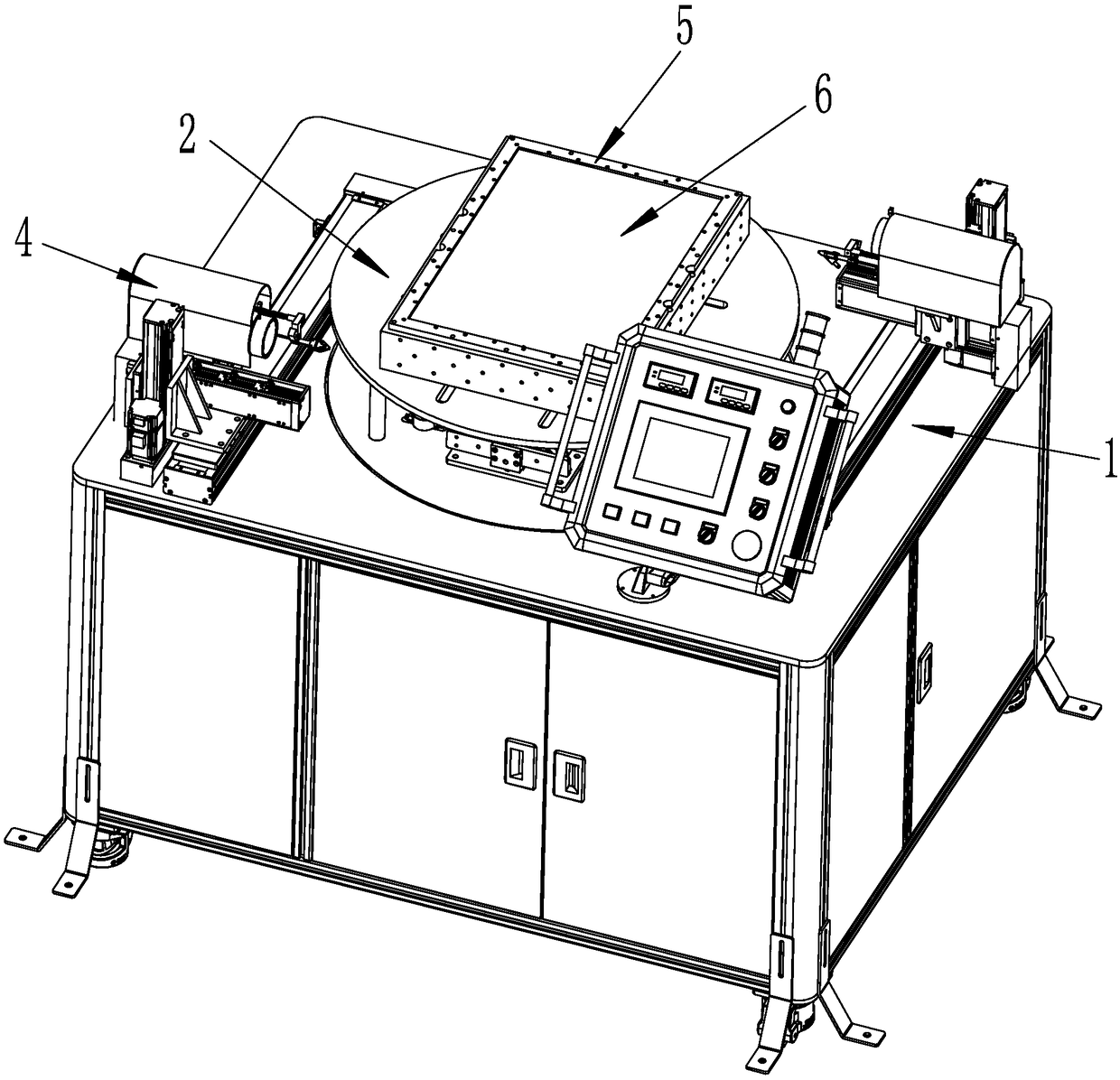

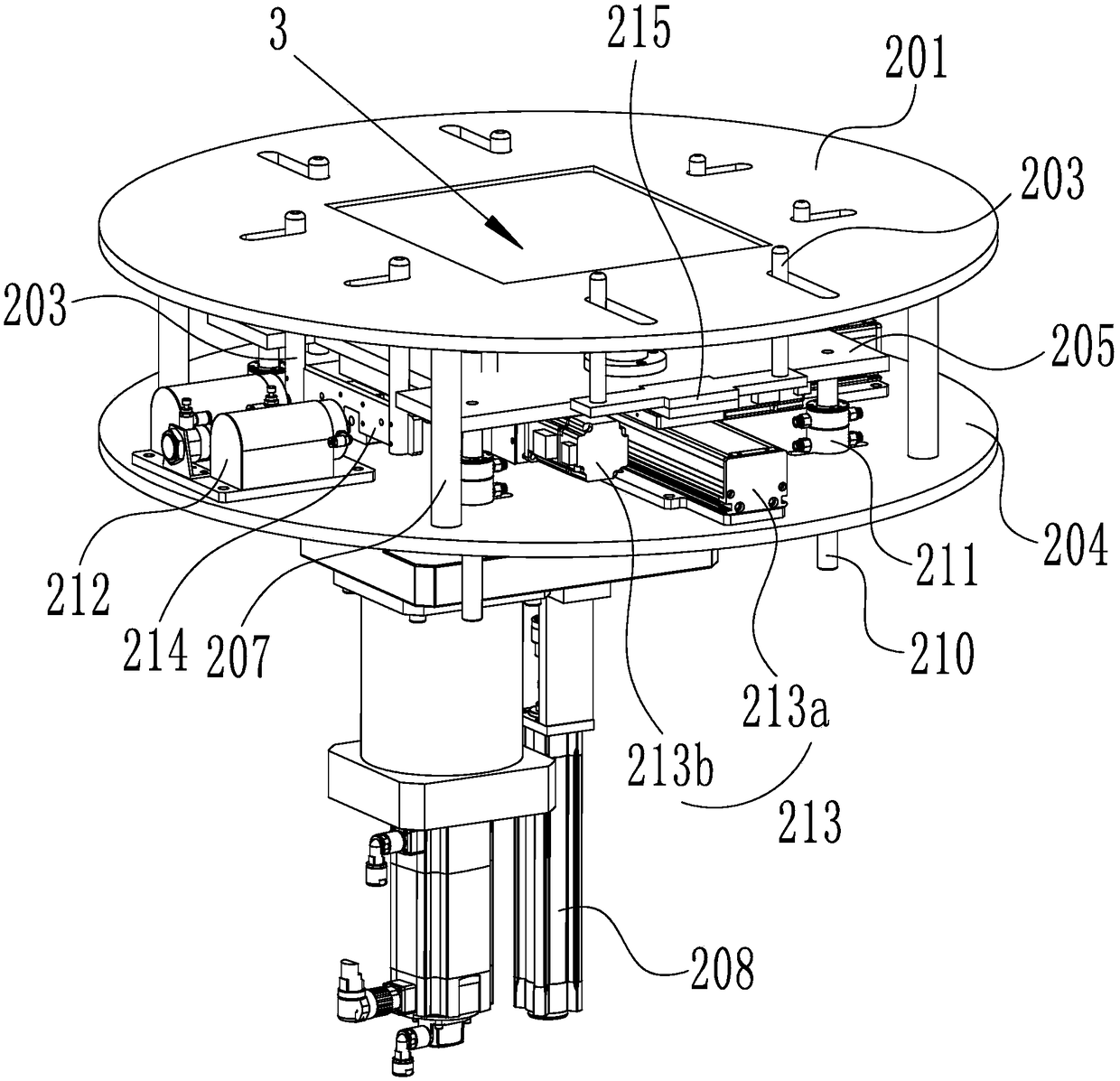

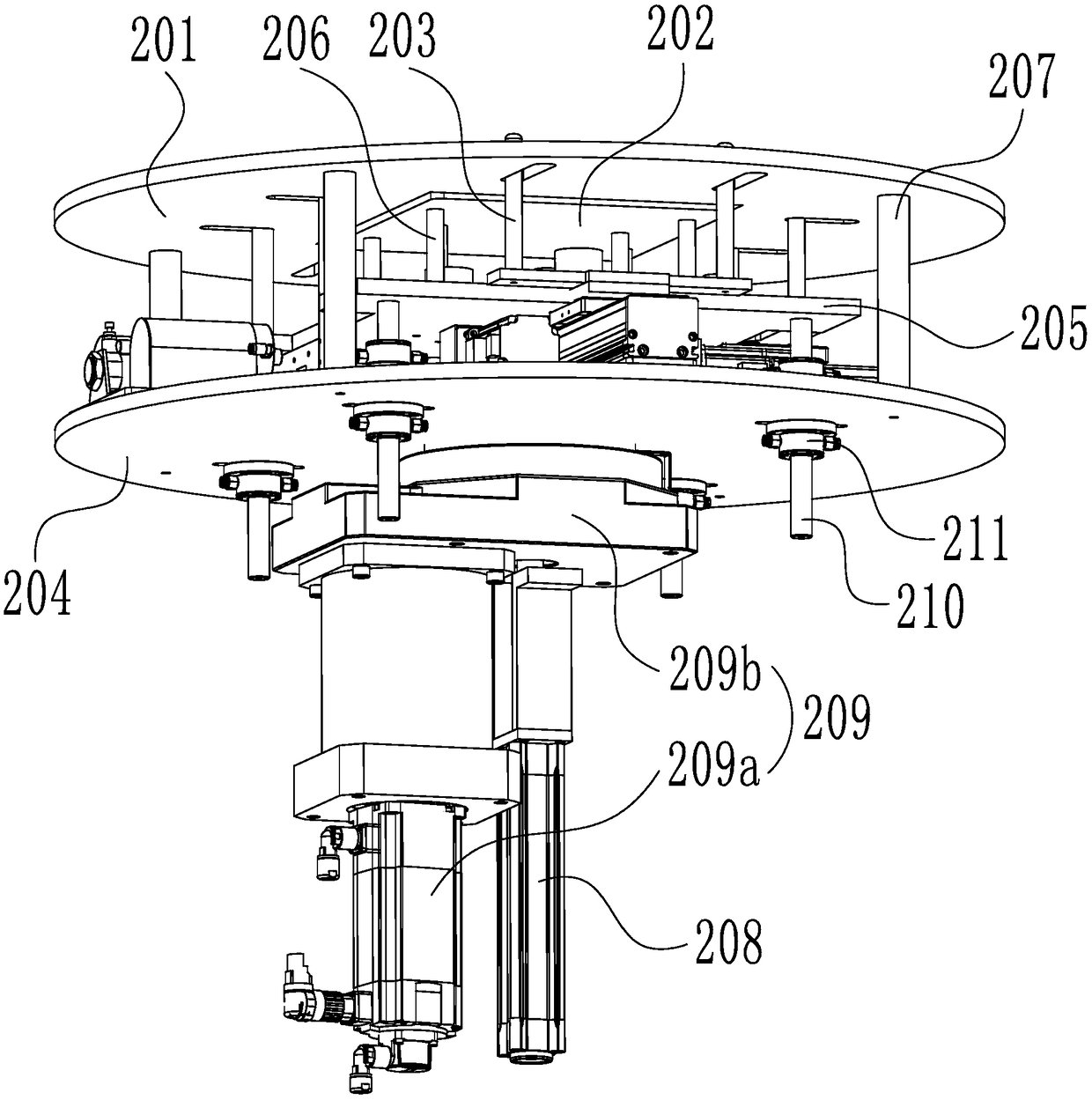

[0038] Such as Figure 1 ~ Figure 3 As shown, an automated flexible calibration platform for meter-scale mirrors includes a base 1 and a turntable 2 rotatably mounted on the upper part of the base 1. The turntable 2 includes an assembly panel located above the base 1 and rotatable relative to the base 1. 201 and a lifting plate 202 that can be lifted and lowered at the center of the assembly panel 201, on the assembly panel 201 along the circumferential direction of the lifting plate 202, there are positioning pins 203 that can approach or stay away from the lifting plate 202. A flexible cleaning pad 3 is provided on the upper surface of the lifting plate 202 , and locking screw assemblies 4 are provided on both sides of the assembly panel 201 .

[0039] See figure 2 and image 3 , a rotating base plate 204 and a lifting mother plate 205 are arranged in par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com