Lip sealing device for piston flushing valve

A technology of lip seals and flushing valves, which is applied to the sealing of engines, flushing equipment with water tanks, valve operation/release devices, etc., and can solve problems such as changes in friction and uneven flushing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

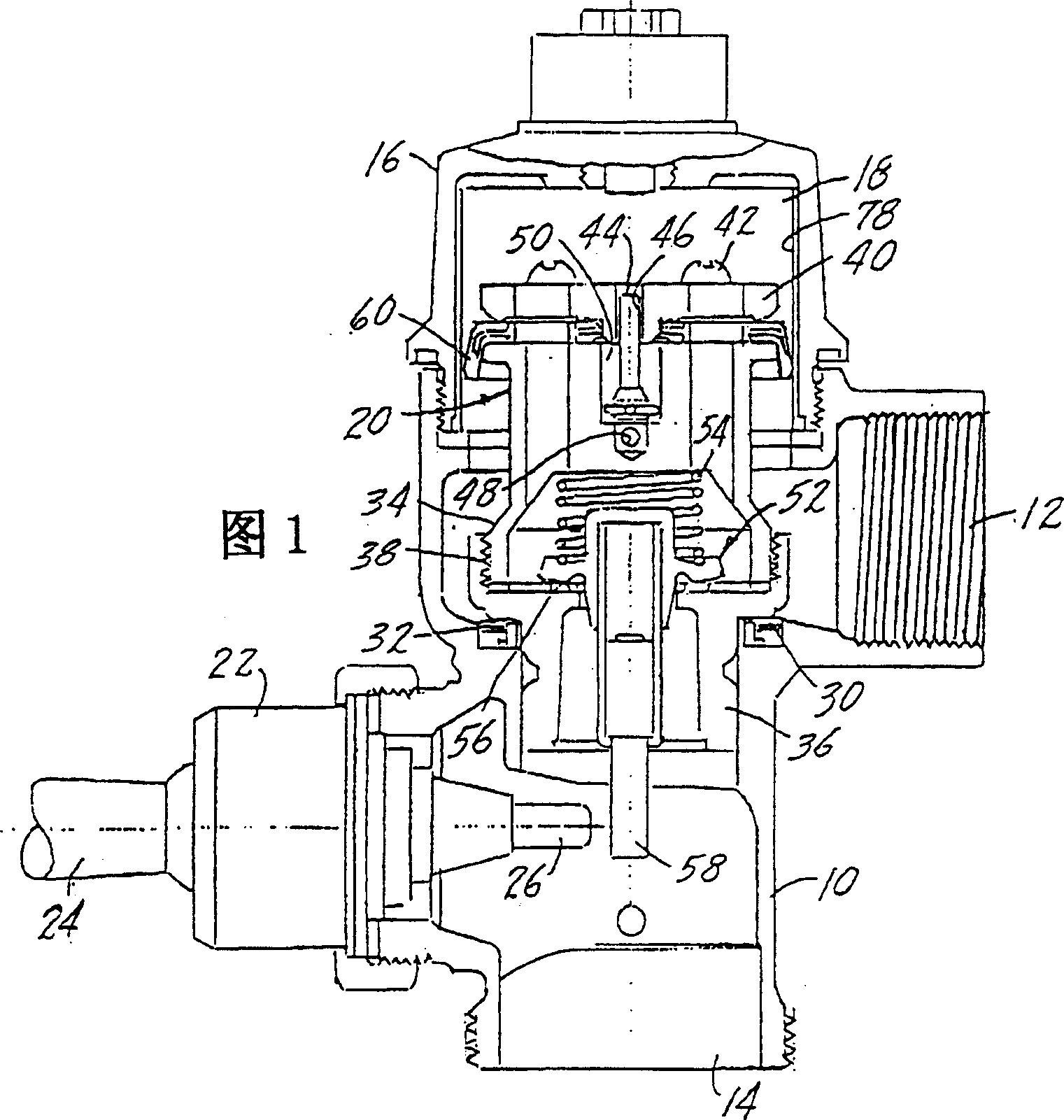

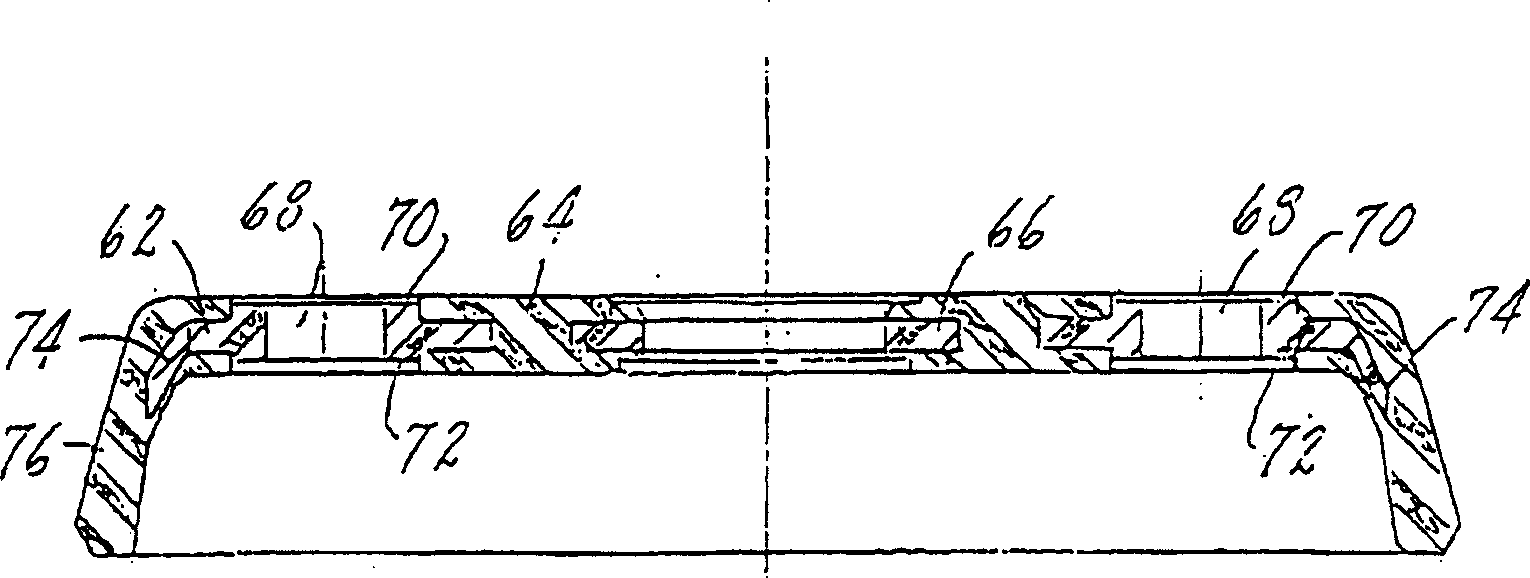

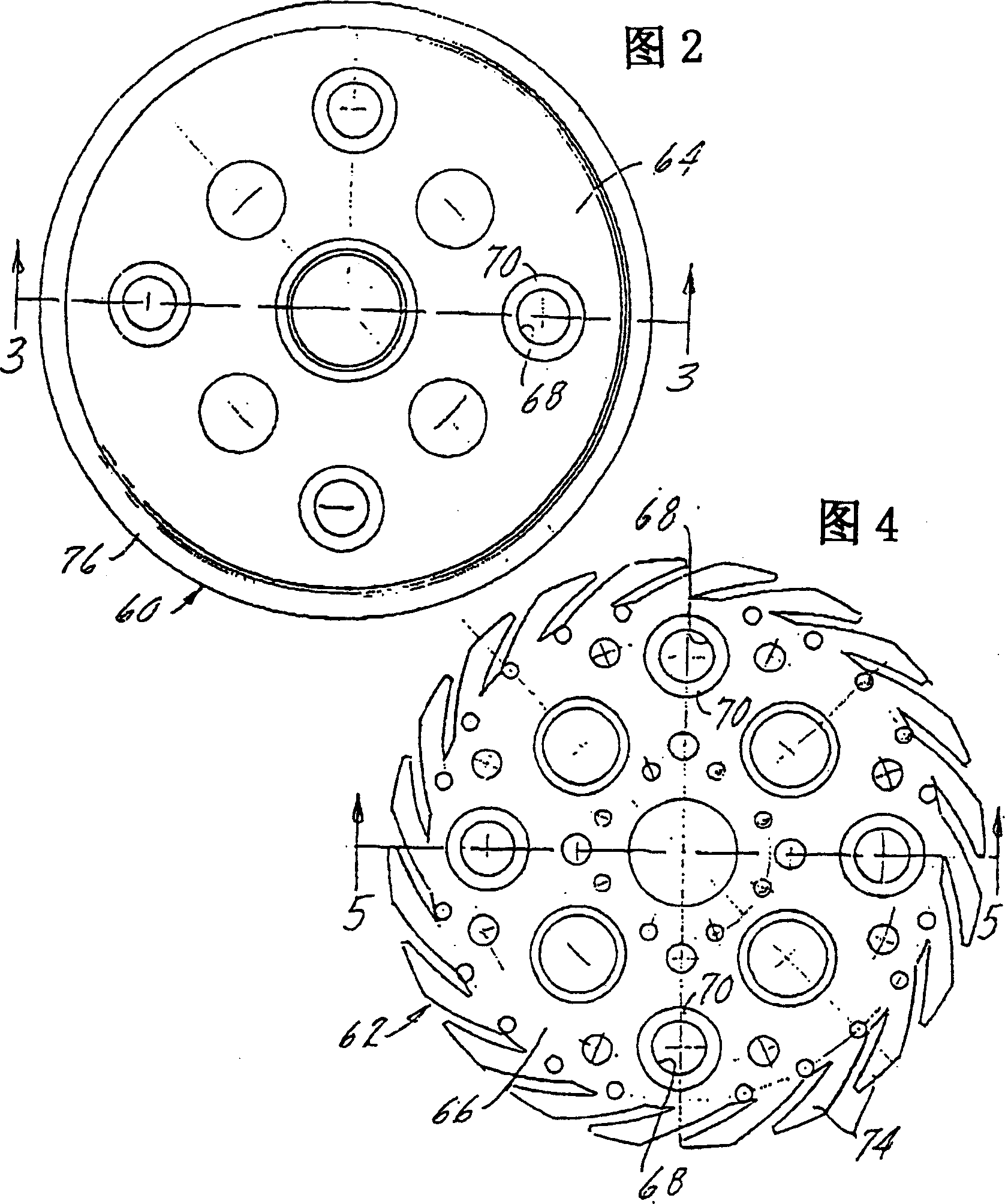

[0037] [37] The present invention relates to an improved seal for a piston flush valve. In existing devices of this type, which are basically made by molding an elastomer over a brass insert, the torque applied by the screw connecting the seal into the piston part can cause the upper edge of the seal to The lower lip expands, reducing the gap between the lip seal and the bore of the flushometer body. This in turn increases the friction between the seal and the bore. Due to the increased friction, the duration of the flush cycle also increases, increasing the amount of water delivered during the operating cycle. Friction is not a problem for the upstroke of the piston because there is a sufficient pressure differential to push the piston upward and the geometry of the seal allows it to move freely in that direction. Friction becomes problematic for the downstroke of the piston, because pressure slowly builds up in the cavity above the piston component, and the geometry of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com