A preparation method of a monodisperse aminated nano-diamond colloidal solution and its secondary dispersion process and application in cell labeling

A technology of nano-diamond and nano-diamond powder, which is applied in the field of preparation of monodisperse aminated nano-diamond colloid solution, can solve the problems of not being able to obtain monodisperse nano-diamond colloid, achieve high yield, low production cost, and cheap and easy-to-obtain reagents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

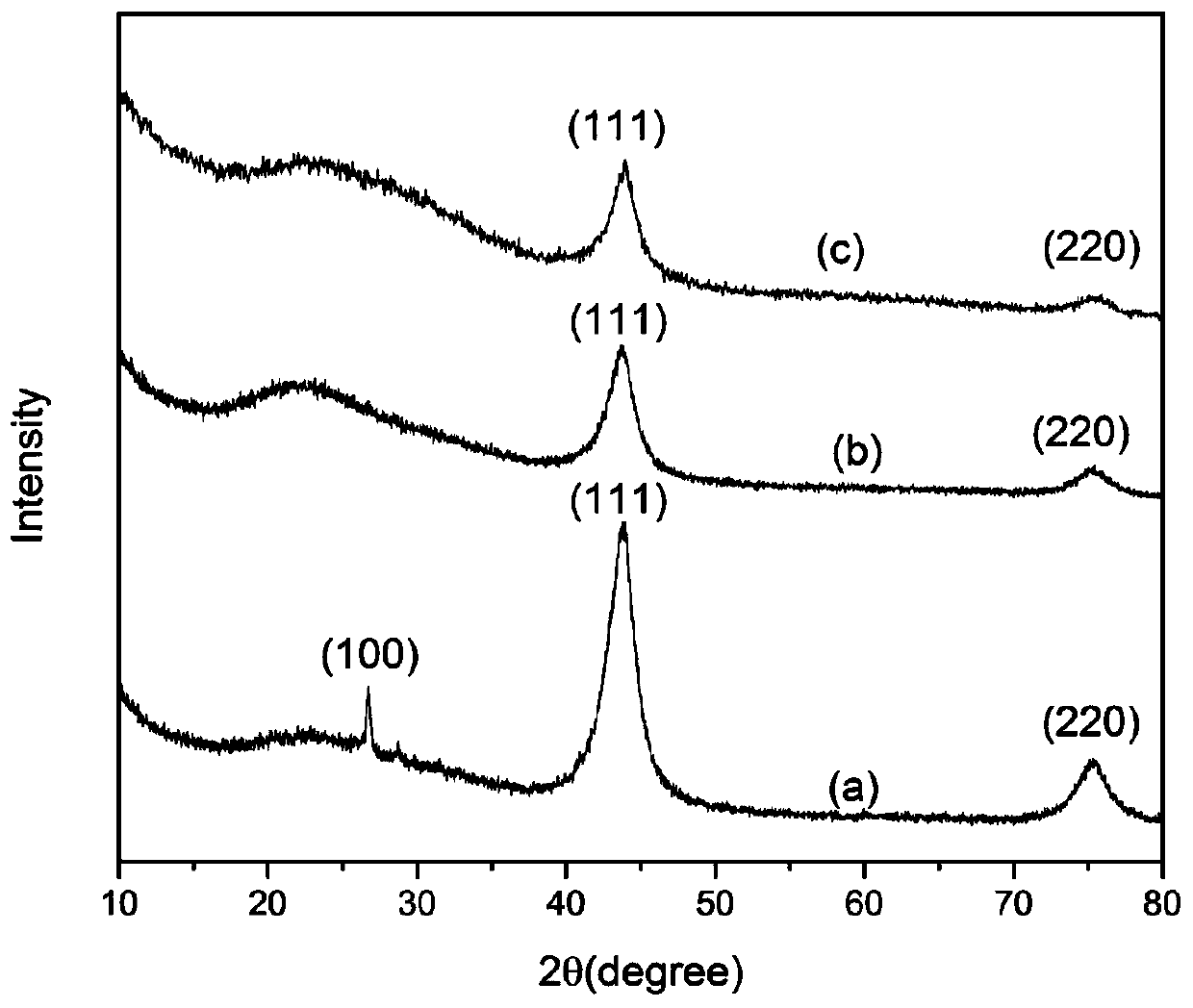

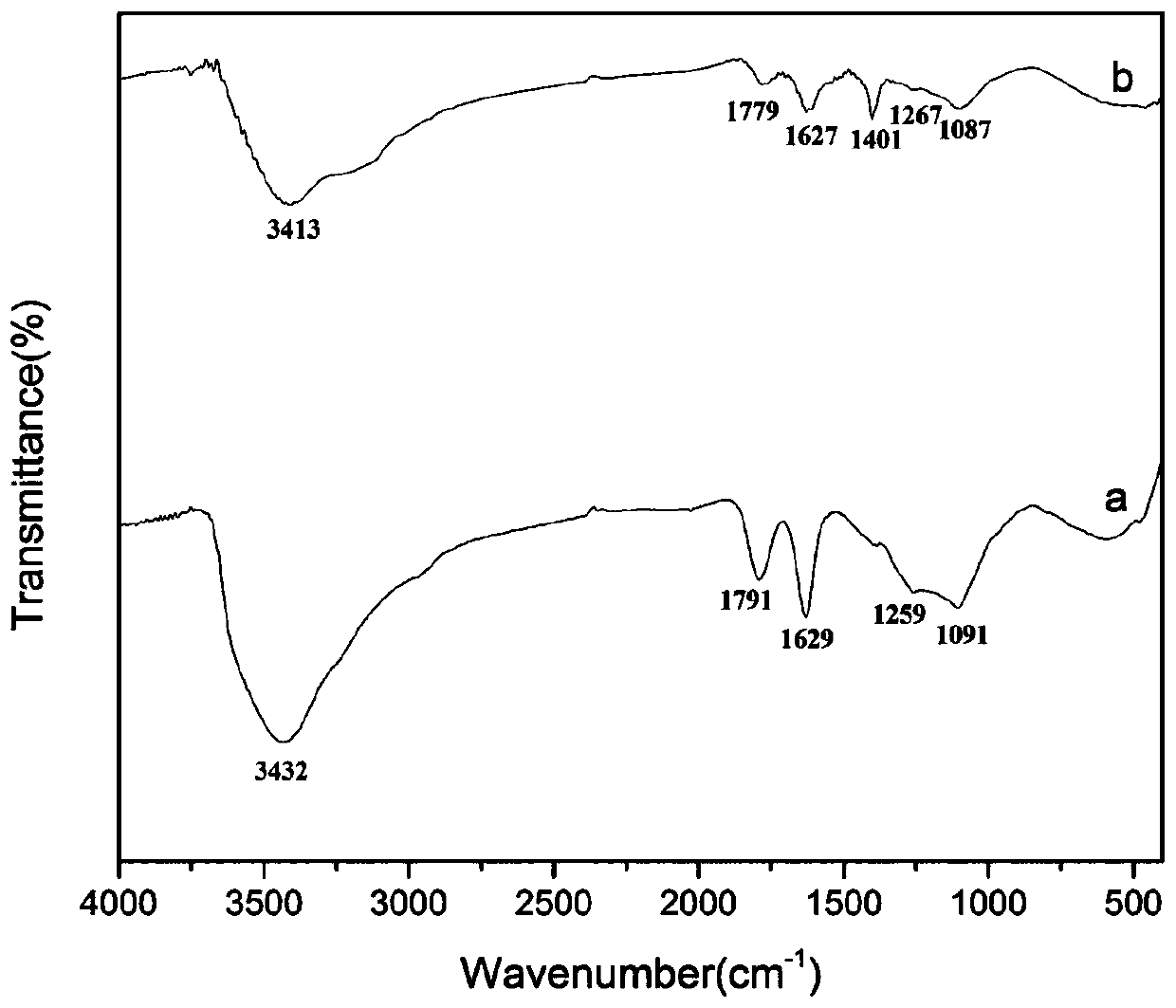

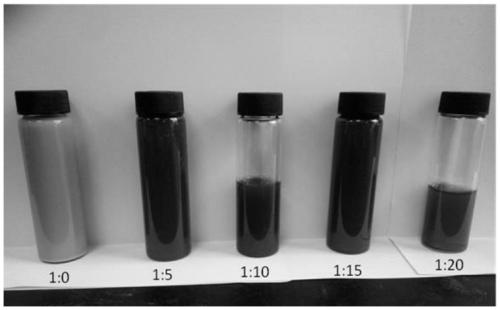

Embodiment 1

[0046] A kind of preparation method of monodisperse aminated nano-diamond colloidal solution of the present embodiment, described method comprises the steps:

[0047] (1) Take ball milling beads (mass ratio of agate bead diameter 6.8mm to small bead diameter 4.2mm 1:5) and put it into a ball mill jar with a volume of 100ml, add 0.5g of the above-mentioned purified nano-diamond and 2.5g of chlorine Sodium chloride was added without adding ammonium chloride, the ball mill (model: QM-1SP2, Nanjing University Instrument Factory) was set at a linear speed of 512 m / min, the ball milling time was 2 hours, the ball mill was turned off, and the ball mill jar was removed after 30 minutes.

[0048] (2) Take out the ball milling beads in the ball milling tank, wash with deionized water (250-300ml, the volume of water can be increased appropriately), and disperse under the action of ultrasound (8000W ultrasound generally does not exceed 1min, 360W ultrasound generally 15min), Centrifuge at...

Embodiment 2

[0053] A kind of preparation method of monodisperse aminated nano-diamond colloidal solution of the present embodiment, described method comprises the steps:

[0054] (1) Take ball milling beads (mass ratio of agate bead diameter 6.8mm to small bead diameter 4.2mm 1:5) and put it into a ball mill jar with a volume of 100ml, add 0.5g of the above-mentioned purified nano-diamond and 2.5g of chlorine Ammonium chloride, 2.5g sodium chloride, set the linear speed of the ball mill (model: QM-1SP2, Nanjing University Instrument Factory) to 512m / min, the ball milling time to 2h, turn off the ball mill, and remove the ball mill jar after 30min.

[0055] (2) Take out the ball milling beads in the ball milling tank, wash with deionized water (250-300ml, the volume of water can be increased appropriately), and disperse under the action of ultrasound (8000W ultrasound generally does not exceed 1min, 360W ultrasound generally 15min), Centrifuge at a centrifugal speed of 10000r / min, set the ...

Embodiment 3

[0064] A kind of preparation method of monodisperse aminated nano-diamond colloidal solution of the present embodiment, described method comprises the steps:

[0065] (1) Take ball milling beads (mass ratio of agate bead diameter 6.8mm to small bead diameter 4.2mm 1:5) into a ball mill jar with a volume of 100ml, add 0.5g of the above-mentioned purified nano-diamond and 5g of chloride Ammonium, 2.5g sodium chloride, set the speed of the ball mill (model: QM-1SP2, Nanjing University Instrument Factory) to 512r / min, the ball milling time to 2h, turn off the ball mill, and remove the ball mill jar after 30min.

[0066] (2) Take out the ball milling beads in the ball milling tank, wash with deionized water (250-300ml, the volume of water can be increased appropriately), and disperse under the action of ultrasound (8000W ultrasound generally does not exceed 1min, 360W ultrasound generally 15min), Centrifuge at a centrifugal speed of 10000r / min, set the time for 5min, and repeat the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com