Divided vertical sinter cooler and sinter cooling method

A cooling machine and sintering ore technology, which is applied in the field of sintering ore cooling machine and sintering ore cooling, subdivided vertical sintering ore cooling machine and sintering ore cooling, which can solve flue gas parameter fluctuations, poor heat transfer effect and reduce waste heat boiler Thermal efficiency value and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0130] According to the first embodiment provided by the present invention, a compartmentalized vertical sinter cooler is provided.

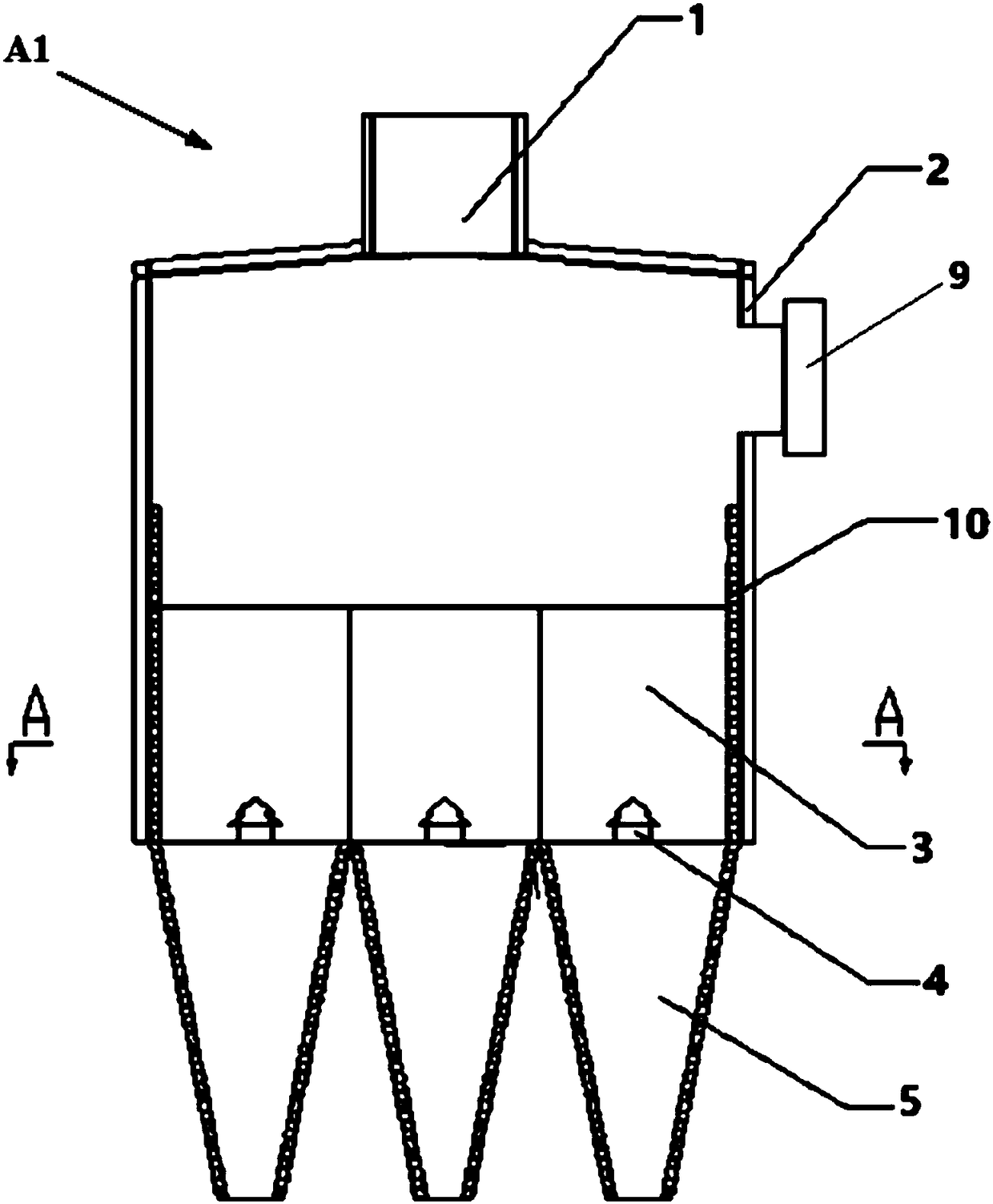

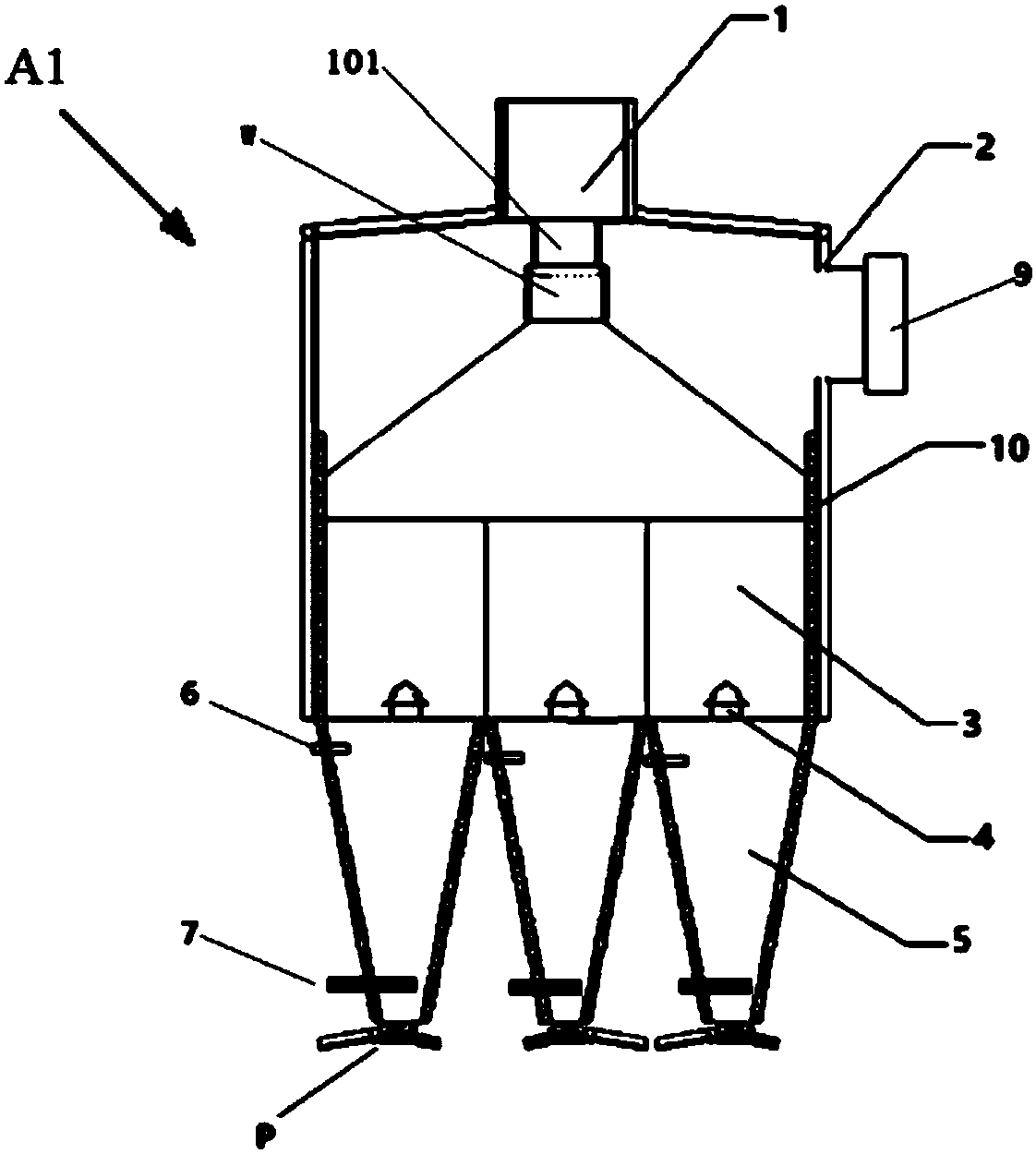

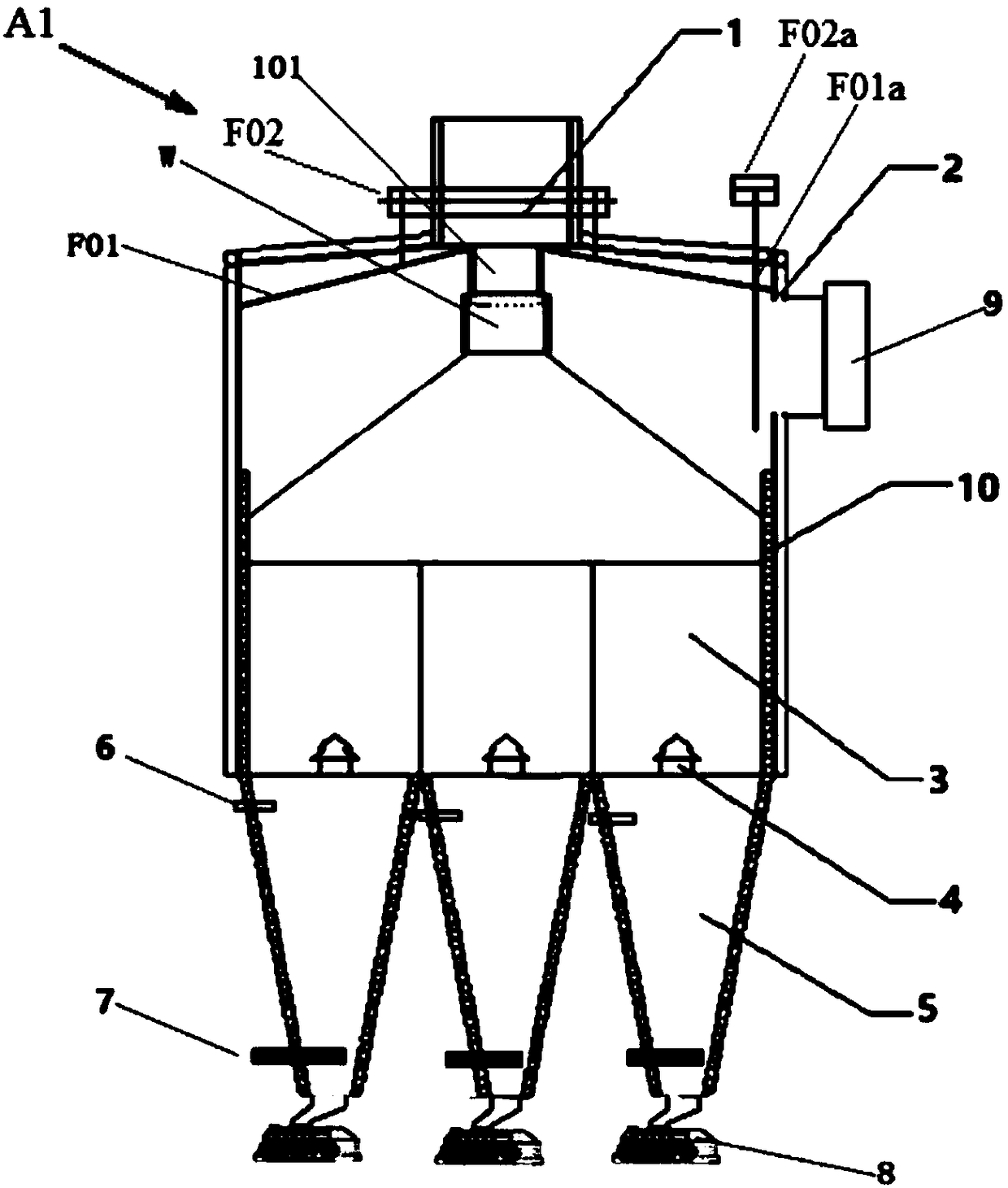

[0131] A compartmentalized vertical sinter cooler, the compartmentalized vertical cooler A1 includes a silo 1 , a tower body 2 , a compartmental frame 3 , an air inlet device 4 , a discharge cone 5 and a hot air outlet 9 . Wherein: the feed bin 1 is set directly above the tower body 2 . The grid frame 3 is arranged in the tower body 2 and is located at the lower part of the tower body 2 . The air inlet device 4 is arranged at the bottom of the tower body 2 . The discharge cone 5 is arranged below the tower body 2 . The grid frame 3 divides the inner lower part of the tower body 2 into a plurality of independent spaces. The hot air outlet 9 is arranged on the top or top of the tower body 2 .

[0132] Preferably, the subdivided vertical cooler A1 also includes a material height adjusting device W. The end of the feed bin 1 is provided with a ...

Embodiment 1

[0197] The height of the tower body 2 is 9 meters, and the length and width of the tower body 2 are 14 meters. The height of the discharge cone 5 is 7 meters. The discharge device P is a double-layer vibrating feeder. Above the interior of the tower body 2, a first ring-shaped radiant heat recovery device F01 is formed by assembling a plurality of ring-shaped hollow plates.

[0198] The diameter of the hood M is 2.5 meters.

[0199] The daily processing capacity of sinter is 8600 tons / day. The temperature of the sintered ore before entering the silo 1 is about 700°C, and the temperature of the hot air at the hot air outlet 9 reaches about 500°C. The recovered heat is used to generate electricity, and the power generation is about 36 kWh.

[0200] Compared with the prior art annular cooler, the advantages are: high power generation, low air leakage rate, small dust emission, simple and reliable equipment, and because of better sealing, the technology of the present inventio...

Embodiment 2

[0203] Repeat embodiment 1, just further be provided with the second radiant heat recoverer F01a at the front end of hot air outlet 9; Adopt shell and tube type heat exchanger, as Figure 18 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com