Turntable structure with built-in scraper

A mud scraper and turntable technology, applied in the direction of cleaning equipment, rotary drilling, rotary drilling rigs, etc., to achieve the effects of highlighting substantive features, improving drilling safety, and excellent mud scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

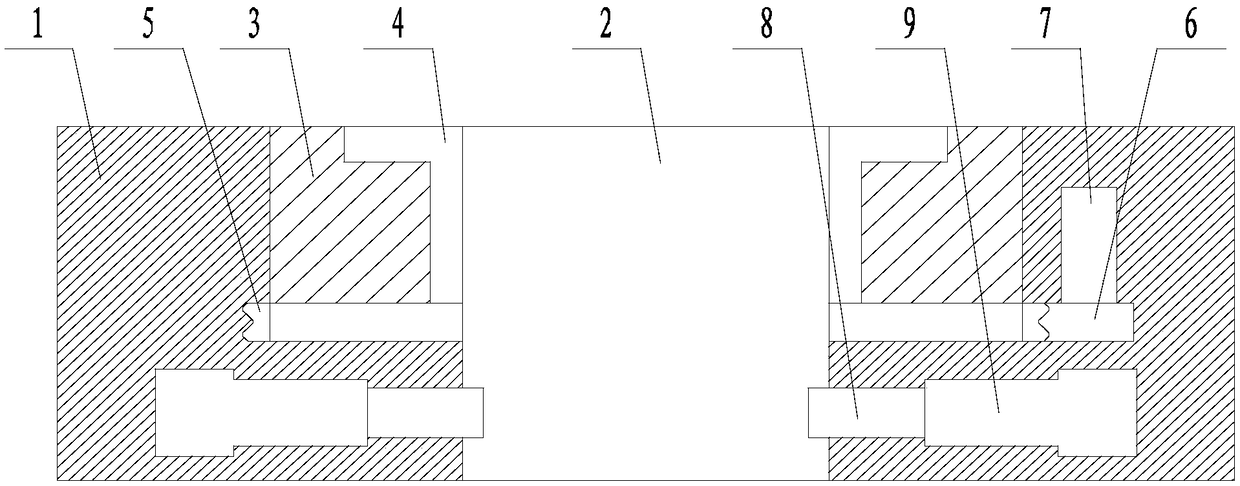

[0022] Such as figure 1 and figure 2 A turntable structure with a built-in mud scraper is shown, including a base body 1, a wellhead passage 2 passing through the base body 1, an annular rotating part 3 capable of rotating around the wellhead passage 2, and a bushing 4 matching the annular rotating part 3 , the annular rotating member 3 is connected to the annular turntable 4, the annular turntable 4 is located inside the base body 1, and the axis of the annular turntable 4 is collinear with the axis of the wellhead channel 2, and the outer edge of the annular turntable 4 is fixed along the circumferential direction. A ring rack 5, a gear 6 and a rotary drive device 7 are arranged in the base body 1, the gear 6 is meshed with the rack 5, and the rotary drive device 7 drives the gear 6 to rotate; the annular turntable 4 There are two mud scrapers 8 symmetrically distributed along the axis of the wellhead passage 2 below the bottom of the wellhead channel 2. The sheets 8 are ...

Embodiment 2

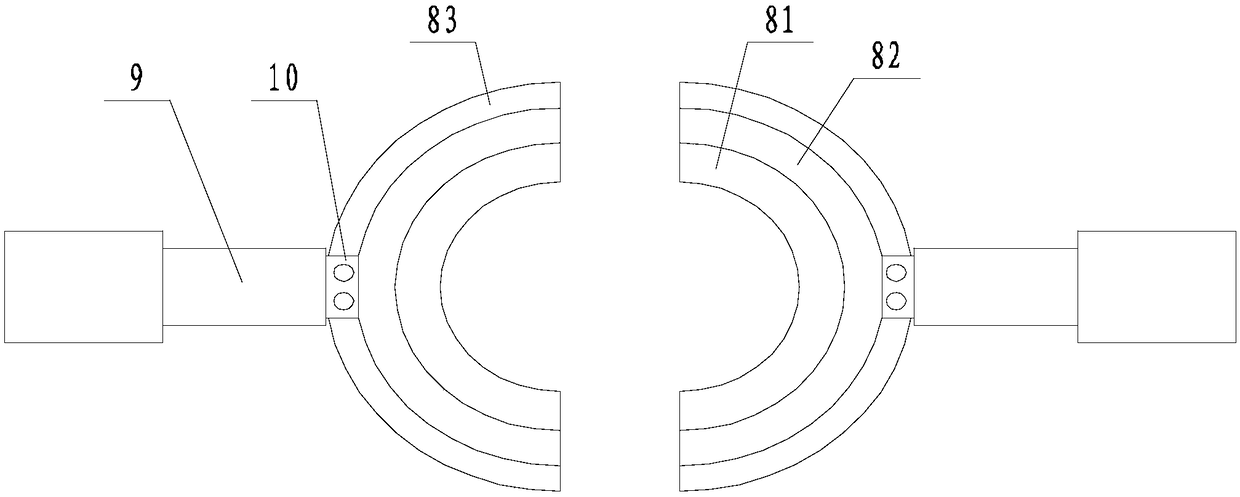

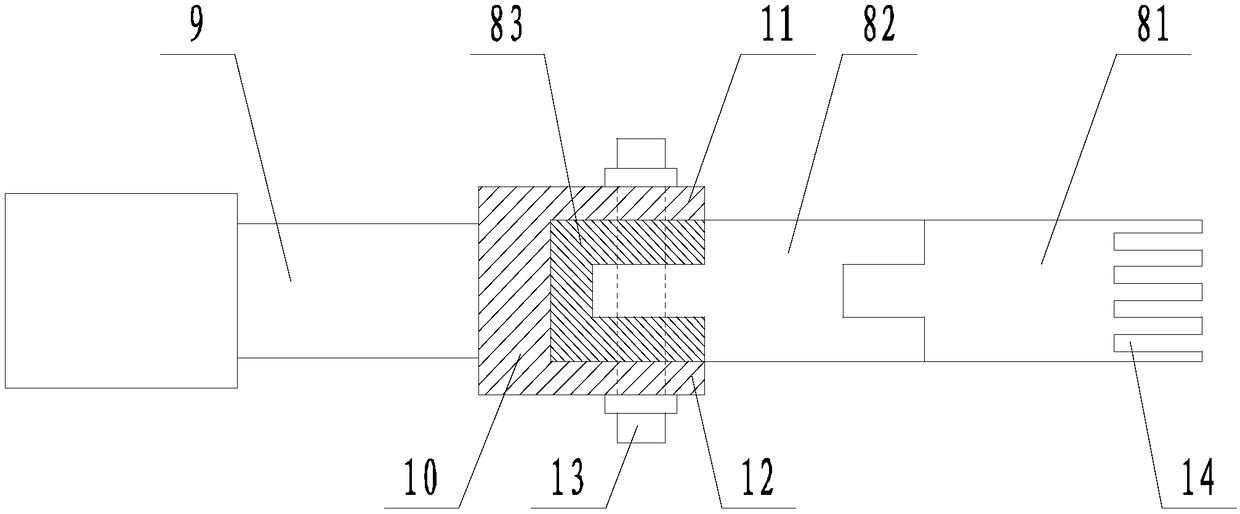

[0024] Such as Figure 1 to Figure 3The structure of a turntable with a built-in mud scraper is shown. On the basis of Embodiment 1, the control switch of the linear drive device 9 is located inside the driller's cabin. The mud scraper 8 is divided into a rubber layer 81, a ceramic layer 82, and a metal layer 83 from the inside to the outside. The inner wall of the ceramic layer 82 is provided with a groove, and the outer wall of the ceramic layer 82 is provided with a flange; The rubber layer 81 is extruded into the groove and glued to the groove wall of the groove; the flange is inserted into the metal layer 83; the driving end of the linear drive device 9 is fixedly connected to the mounting body 10. The installation body 10 includes an upper flange 11 and a lower flange 12 respectively located on the upper and lower sides of the metal layer 83, and also includes a The bolts 13; the inner wall of the rubber layer 81 is provided with several parallel cutouts 14. The rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com