Method for repairing and strengthening slanting rafter and purlin joint of ancient building

A technology for ancient buildings and rafters is applied in the field of reinforcement and repair of oblique palm rafters and purlin joints of ancient buildings, and can solve the security threat, flexibility and anti-torsion ability of oblique palm rafters and purlin joints. Insufficient, weakened nail strength and other problems, to achieve the effect of reducing the number of roof maintenance, environmental protection, and reducing the probability of roof damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

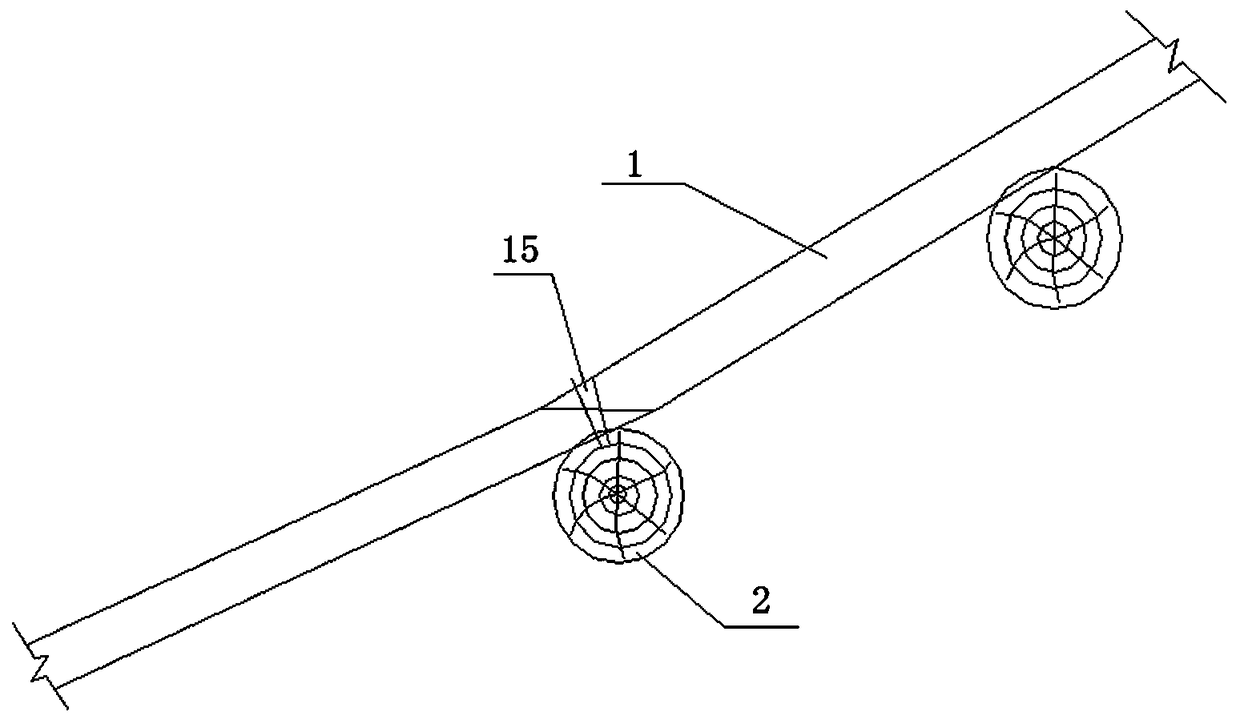

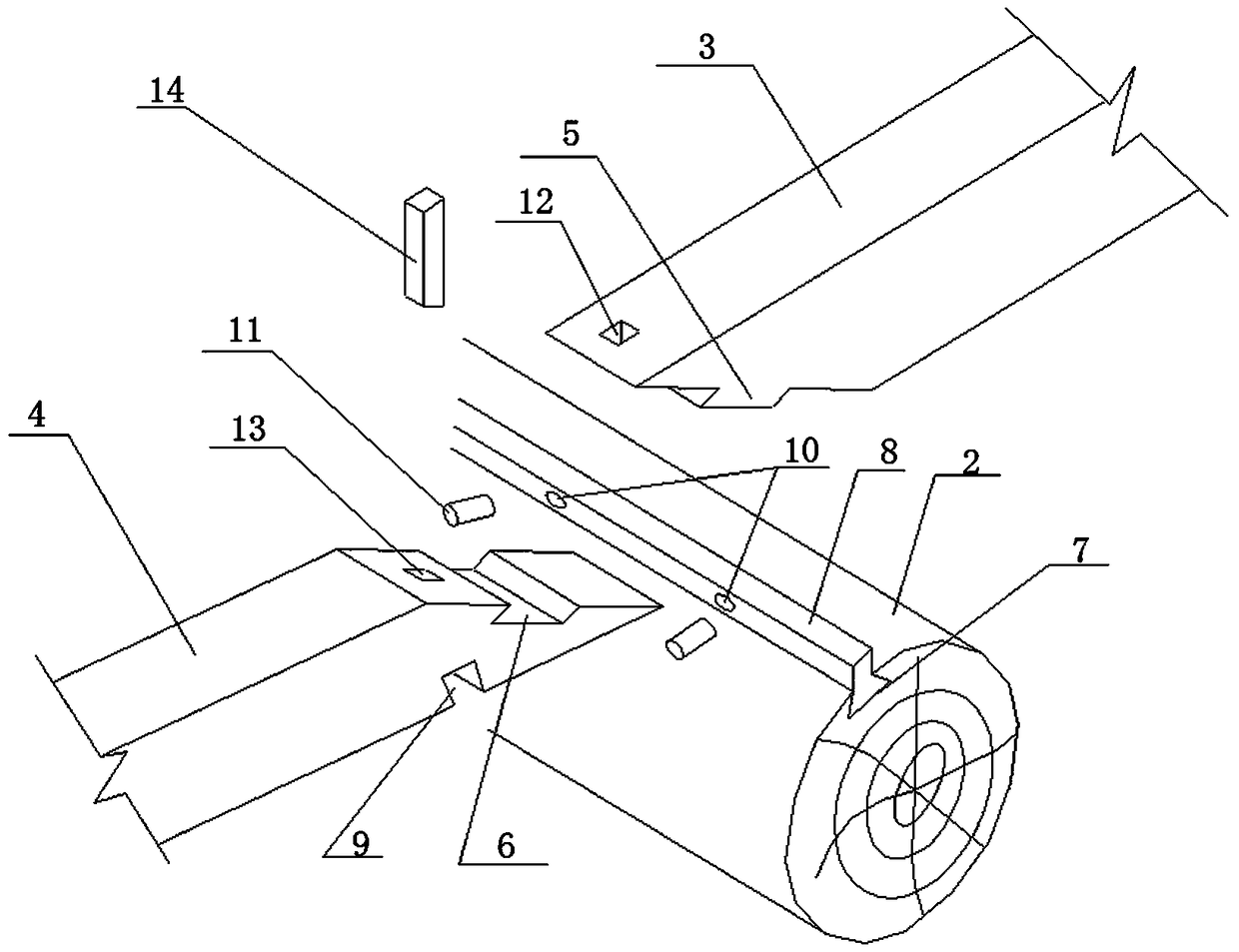

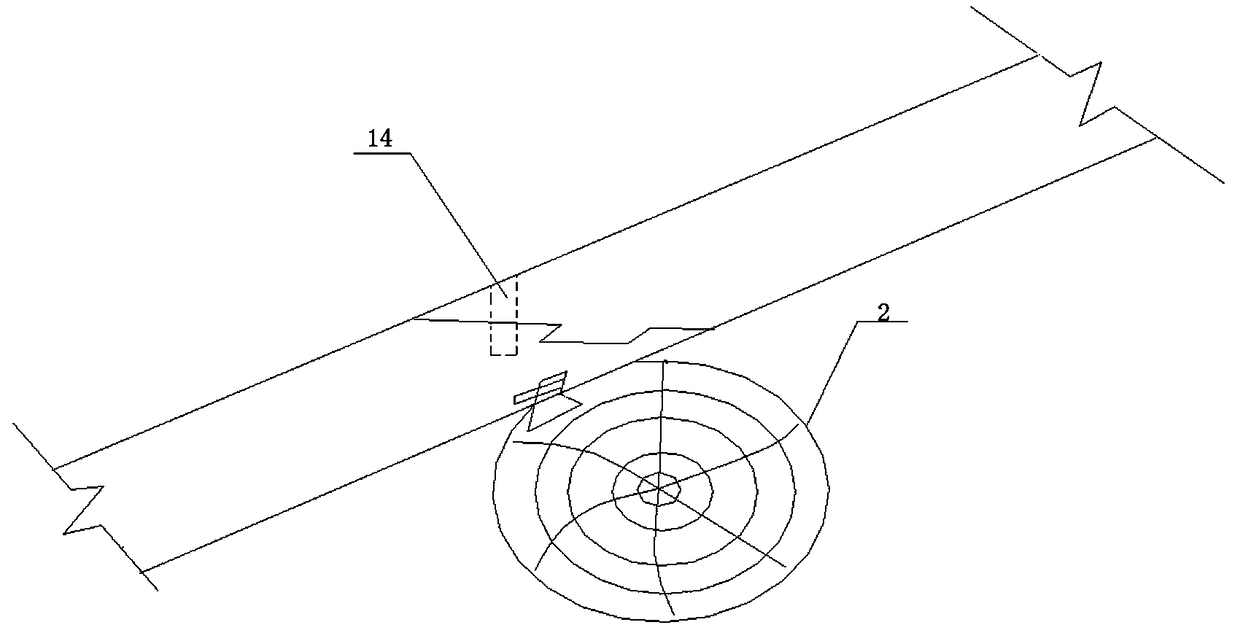

[0028] Due to age, wind, rain and other factors, the roof of ancient buildings is prone to damage, displacement and cracking of the gray back layer, resulting in roof leakage, wooden watchboards and rafters. If the rafters are seriously decayed and cannot meet the requirements of their bearing capacity, they must be replaced with new ones. This patented technology can be used for the reinforcement and repair of all oblique palm type rafters and purlin joints.

[0029] (a) At the joints between all sloping palm-shaped rafters and purlins, such as: the upper golden purlin, middle golden purlin, lower golden purlin, etc., where the rafters overlap with the rafters, if the rafters are severely decayed and need to be replaced with new ones, first determine the decay For the rotten area, remove the roof tiles in this area, shovel off the corresponding roof gray back, uncover the wooden watch board here, and remove the rotten rafters to replace them with new ones. The newly replaced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com