Method for preparing superhydrophobic antibacterial fabric based on quaternary silica

A silicon dioxide and antibacterial fabric technology, applied in plant fiber, biochemical fiber treatment, textile and papermaking, etc., can solve the problems of application limitation, fluorine-containing compounds have great environmental and ecological impact, and affect fabric color and luster, and achieve pure color and light, Environmentally friendly and brightly colored fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

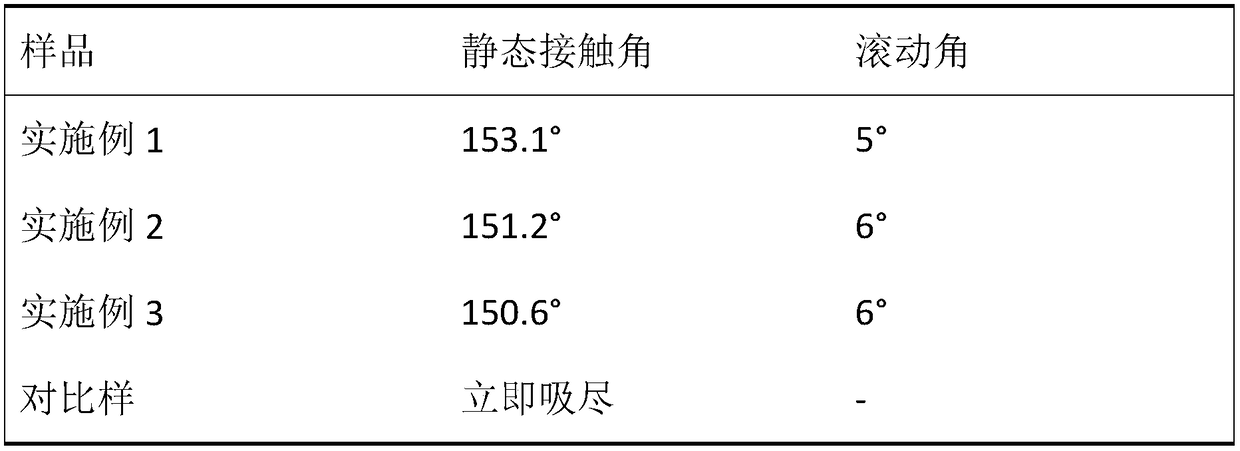

Embodiment 1

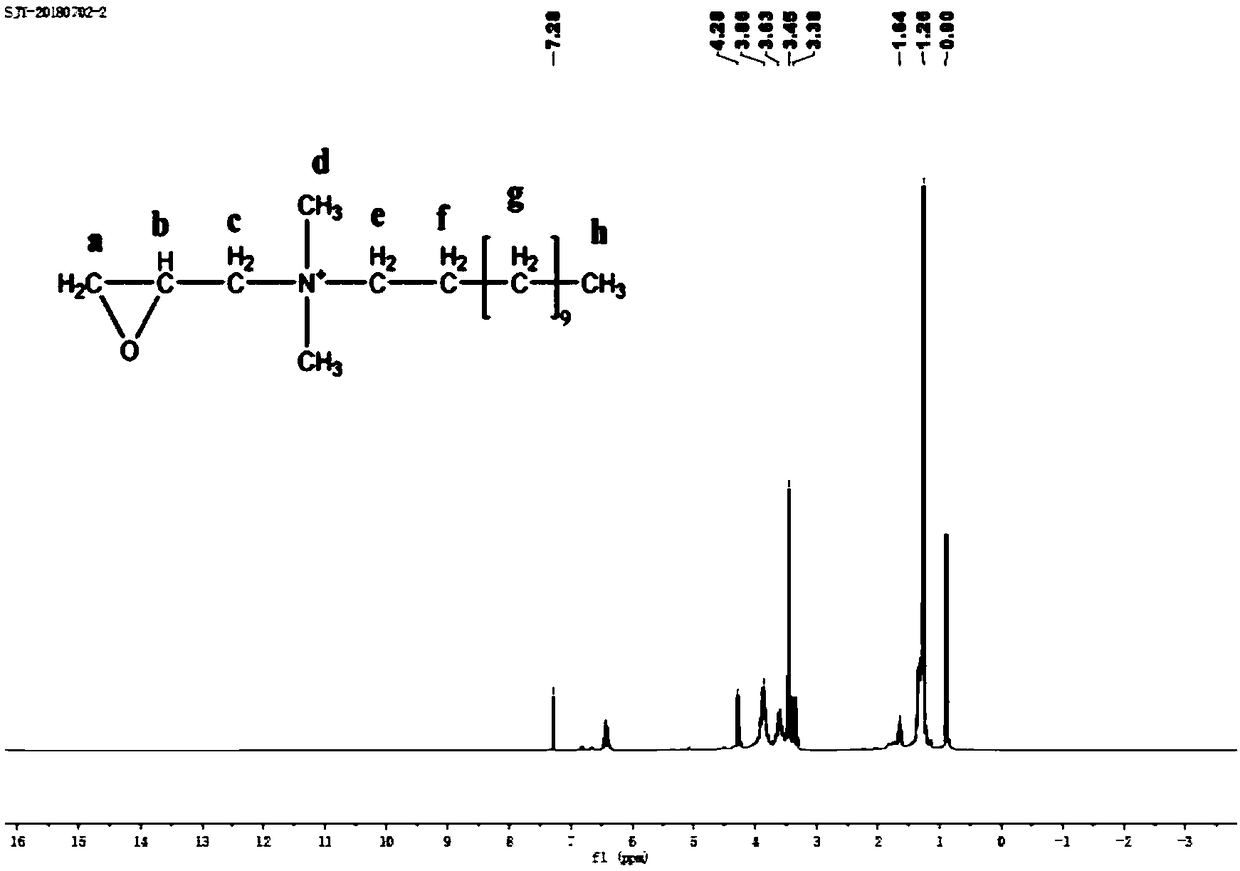

[0034] (1) Synthesis of antibacterial compounds: Take 10.65g of N,N-dimethyldodecylamine and 25g of isopropanol in a three-necked flask, then slowly drop in 6.01g of epichlorohydrin, stir evenly, and heat up to 50°C After reacting for 5 h, anhydrous ether was poured into the obtained product to produce a white precipitate, which was centrifuged and washed several times with anhydrous ether, and dried in vacuo at 60° C. for 12 h to obtain a white solid.

[0035] (2) Amino-modified silica: Take 4g of silica in a round-bottomed flask, add 100ml of toluene for ultrasonic dispersion, heat up to 100°C, add 0.2g of KH-550, and reflux for 5 hours. Disperse in isopropanol and perform multiple washes with isopropanol.

[0036] (3) Grafting silica with EPDDAC: Add 0.2 g of the product obtained in step (1) to the dispersion obtained in step (2), react at 40°C for 12h, and vacuum-dry at 70°C for 5h after centrifugal washing.

[0037] (4) Preparation of padding liquid: get 0.4g of IMK-2035...

Embodiment 2

[0045] (1) Synthesis of antibacterial compounds: Take 10.65g of N,N-dimethyldodecylamine and 30g of isopropanol in a three-necked flask, then slowly drop in 4.63g of epichlorohydrin, stir evenly, and heat up to 60°C After reacting for 4 hours, anhydrous diethyl ether was poured into the obtained product to produce a white precipitate, which was centrifuged and washed several times with anhydrous diethyl ether, and then vacuum-dried at 60° C. for 12 h to obtain a white solid.

[0046] (2) Amino-modified silica: Take 4g of silica in a round-bottomed flask, add 100ml of toluene for ultrasonic dispersion, heat up to 100°C, add 0.3g of KH-550, and reflux for 5 hours. The obtained product is centrifuged and re- Disperse in isopropanol and perform multiple washes with isopropanol.

[0047] (3) Grafting silica with EPDDAC: Add 0.4 g of the product obtained in step (1) to the dispersion obtained in step (2), react at 40°C for 15 hours, and vacuum-dry at 70°C for 5 hours after centrifug...

Embodiment 3

[0052] (1) Synthesis of antibacterial compounds: Take 8.52g of N,N-dimethyldodecylamine and 25g of isopropanol in a three-necked flask, then slowly drop in 6.47g of epichlorohydrin, stir evenly, and heat up to 70°C After reacting for 3 hours, anhydrous diethyl ether was poured into the obtained product to produce a white precipitate, which was centrifuged and washed several times with anhydrous diethyl ether, and then vacuum-dried at 60° C. for 12 h to obtain a white solid.

[0053] (2) Amino-modified silica: Take 4g of silica in a round-bottomed flask, add 100ml of toluene for ultrasonic dispersion, heat up to 110°C, add 0.3g of KH-550, and reflux for 4 hours. The obtained product is centrifuged and re- Disperse in isopropanol and perform multiple washes with isopropanol.

[0054] (3) Grafting silica with EPDDAC: Add 0.4 g of the product obtained in step (1) to the dispersion obtained in step (2), react at 50°C for 10 hours, and vacuum-dry at 70°C for 5 hours after centrifuga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com