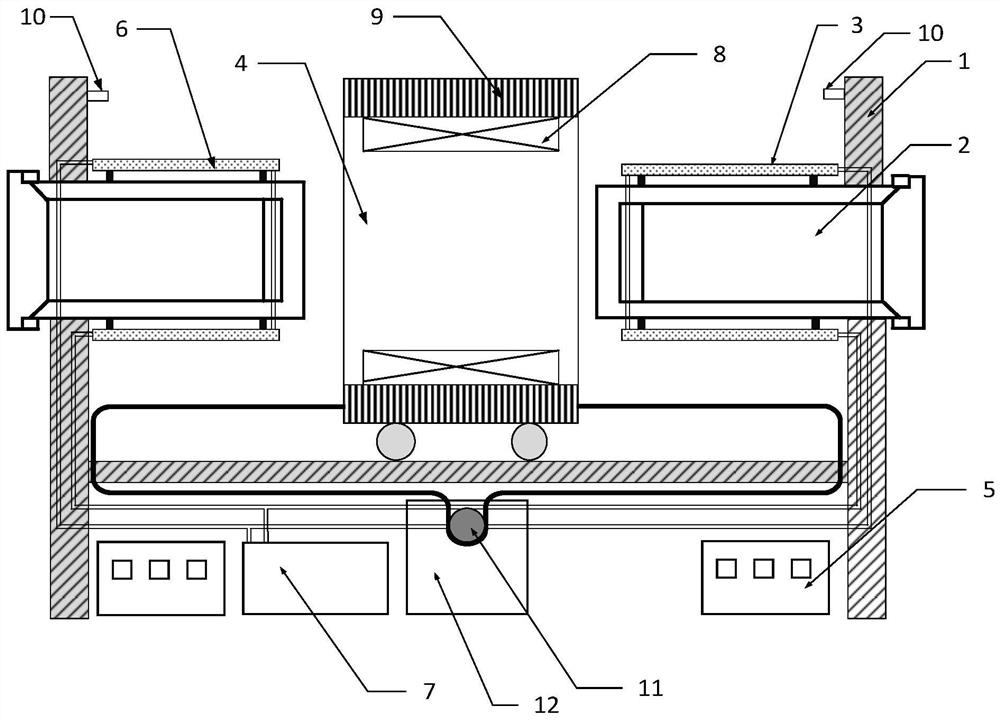

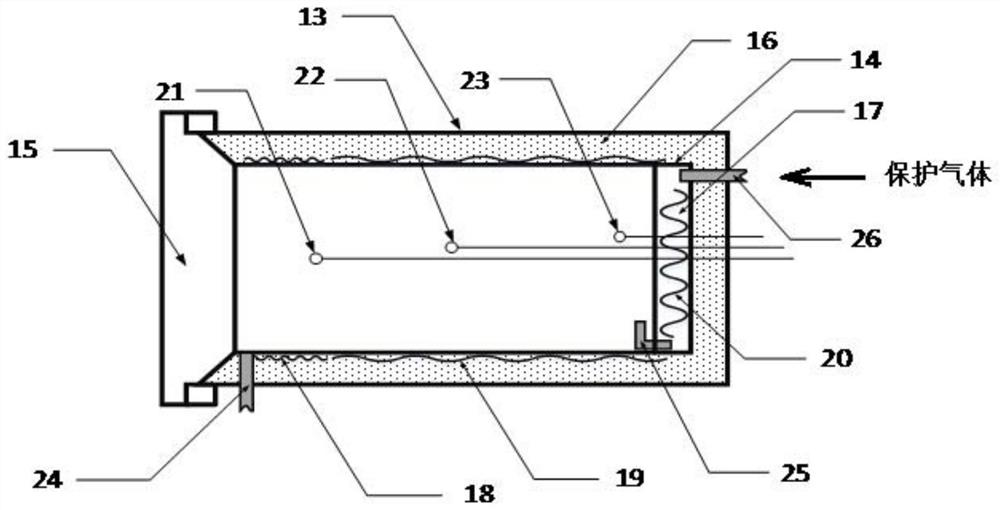

A magnetic field heat treatment furnace

A heat treatment furnace and magnetic field technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of large difference in magnetic core performance, unstable magnetic core performance, complex process and operation, etc., to improve utilization rate, Easy to operate, easy to adjust and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The heat treatment in the non-vacuum treatment process, the specific steps are: open the protective atmosphere device, pass the protective gas into the furnace; place the magnetic core in the furnace, start the power supply of the control cabinet, and control the corresponding temperature by multiple temperature control meters in the control cabinet 5. Multiple heating elements are used to adjust the temperature in the furnace, which can be divided into three processes: preheating, heating, and heat preservation. The temperature adjustment range can be, for example, 100-600°C; during the heating process, a magnetic field is applied to the magnetic core and then removed. Under the limit of the position of the proximity switch, the fixing device with the permanent magnet is moved to the position of the heating furnace through the magnetic field controller, and the withdrawal action is reversed; the power is turned off, the magnetic core is directly taken out, and the magnet...

Embodiment 2

[0046] Heat treatment in the non-vacuum treatment process, the specific steps are: open the protective atmosphere device, pass protective gas into the furnace; place the magnetic core in the furnace, add a magnetic field and start the control cabinet power; turn off the power, withdraw the magnetic field, and the furnace The core cools with the furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com