Automatic lime slaking control device

An automatic control device, lime technology, applied in the direction of using alkaline earth compounds for purification, etc., can solve the problems of relatively large fluctuation of lime milk concentration, proportional adjustment of the elimination time, and large influence on process control stability, and achieves simple structure, elimination of And the effect of high completion rate and small equipment wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

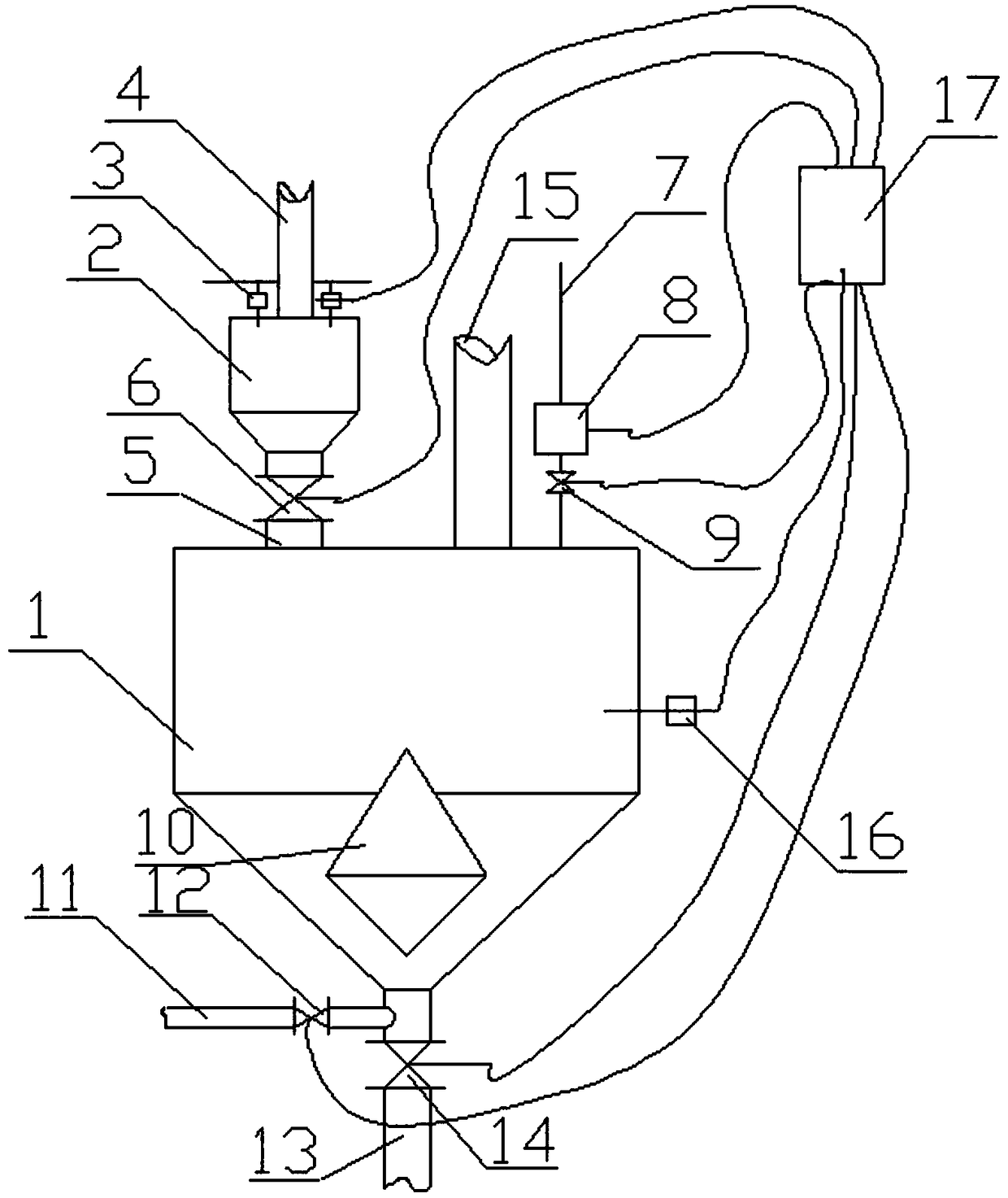

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0026] Such as figure 1 As shown, a lime elimination and automatic control device includes a lime elimination and bucket 1, a lime delivery part, a water inlet part, a compressed air part, a lime milk discharge pipe 11 and a PLC controller 17. The upper part of the lime elimination bucket 1 is a cylindrical structure, and the lower part is a conical structure. A deflector 10 for increasing the contact area between lime and water is provided at the lower part of the lime elimination bucket 1 . The deflector 10 is composed of two cones connected up and down, and the bottom surfaces of the two cones are connected together and fixed at the lower part of the lime silencing bucket 1 . An air diffuser pipe 15 is vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com