Method for preparing biogasoline by catalytic hydrogenolysis on straws

A technology of biogasoline and catalytic hydrogenolysis, which is applied in the field of energy utilization of agricultural waste, can solve the problems of low yield and high requirements for production equipment, and achieve the effects of low oxygen content, avoiding material loss, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 rice straw wax lipid removal and lignin treatment

[0028] (1) Rice straw pretreatment: Cut the rice straw into small pieces of about 15 cm, wash it with deionized water, and dry it in a ventilated place for 3 days; crush and sieve the air-dried rice straw product; The 40 mesh sieve but the stalks that cannot pass through the 60 mesh sieve are placed in airtight plastic bags and stored at -20°C.

[0029] (2) Rice straw degreasing wax: Take 4g of dried rice straw wrapped with gauze silk and put it into a Soxhlet extractor, extract with 150ml ethanol solution at 105°C for 3 hours, control the reflux at 4-6 times per hour, Then take out the rice straw and dry it.

[0030] (3) Removal of lignin from rice straw: Weigh 3g of fat-removed waxy rice straw into a round bottom flask, then add 100ml of water, 0.75ml of acetic acid, and 0.6g of sodium chlorite in sequence, and heat in an oil bath at 75°C for 3h , add 0.75ml acetic acid and 0.6g sodium chlorite per hou...

Embodiment 2

[0031] Embodiment 2 each biofuel preparation example

preparation example 1

[0033] In a 50mL high-temperature and high-pressure reactor, add 0.1g of lignin-removed and fat-waxy rice straw, 0.1mmol RhCl 3 , 2mmol sodium iodide, 2.875ml water, 0.125ml HCl (37wt%), 3ml toluene, seal the reactor, fill with hydrogen until the pressure in the reactor is 300psi, stir and rapidly heat to the temperature of the mixture in the reactor is 140°C , keep the temperature for 4h, after that, cool the reactor to room temperature with an ice-water bath, and collect the organic phase.

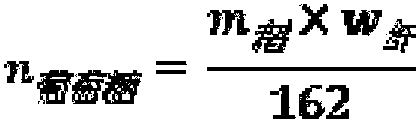

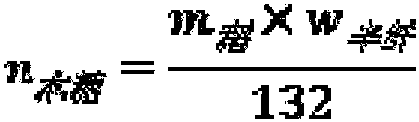

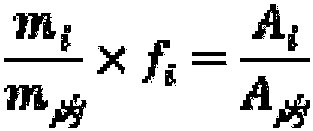

[0034] After GC-MS quantitative analysis combined with LC and GC quantitative analysis of the components and their contents in the organic phase, after calculation, it was obtained that the yield of 2-methylfuran in the product was 21.6%, and the yield of 2-methyltetrahydrofuran was 21.6%. The yield is 55.6%, the yield of 2,5-dimethyltetrahydrofuran is 6.4%, the yield of 2,5-dimethylfuran is 15.5%, the yield of 2-hexanone is 5.4%, and the yield of 3-methylcyclo The productive rate of pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com