Method for refining carnosic acid through molecule distillation

A carnosic acid and molecular distillation technology, applied in molecular distillation, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of low product extraction rate, high production cost, easy oxidation, etc., and achieve production intensity The effect of low, low production cost and short operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for purifying carnosic acid by molecular distillation, comprising the following steps

[0029] (1) Carnosic acid solubilization: Take 1 kg of carnosic acid product with a content of 15% initially extracted by conventional methods, add 2 kg of polyethylene glycol 400, stir and dissolve at 65±2°C;

[0030] (2) Dehydration and degassing by one-stage thin film distillation: the carnosic acid added with co-solvent was pumped steadily into the first-stage thin-film distillation column at a flow rate of 40ml / min for dehydration and degassing by one-stage thin-film distillation. The heating temperature is 90°C, the vacuum degree is 100-200Pa, the rotating speed of the scraping film is 100rpm, and the discharge condensation temperature is 65°C;

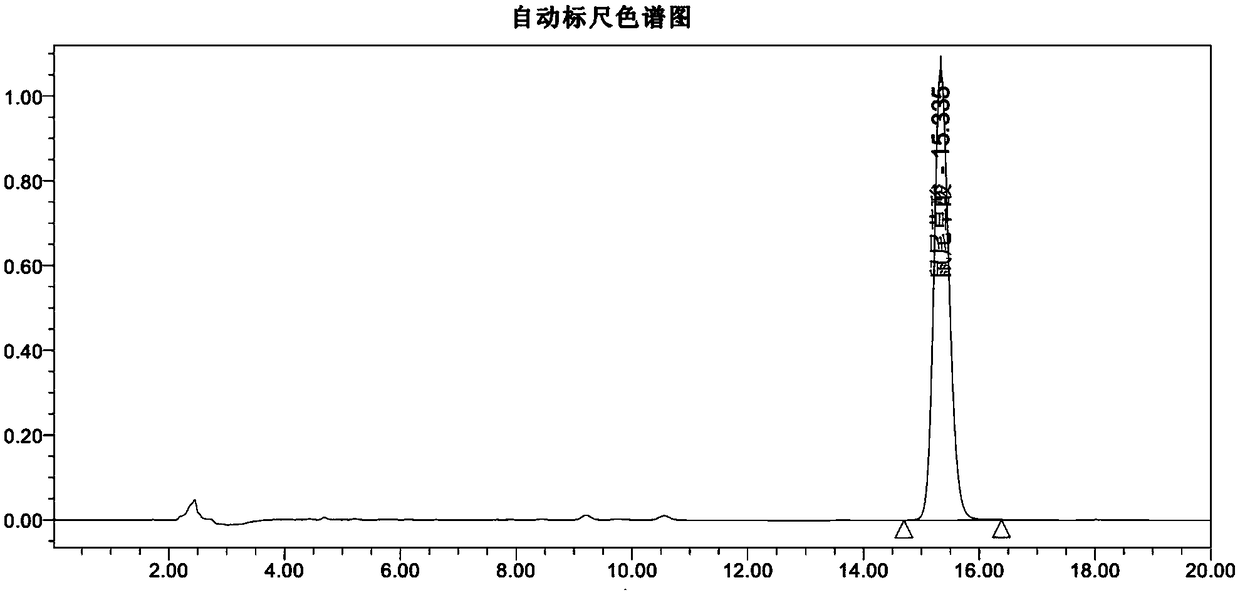

[0031] (3) Secondary molecular distillation separation: pump the dehydrated and degassed liquid into the secondary molecular distillation at a flow rate of 40ml / min for secondary molecular distillation separation to obtain 0.05...

Embodiment 2

[0034] A method for purifying carnosic acid by molecular distillation, comprising the following steps:

[0035] (1) Carnosic acid solubilization: Take 1.2kg of carnosic acid product with a content of 23% initially extracted by conventional methods, add 2kg of propylene glycol and stir to dissolve at 65±2°C;

[0036] (2) Dehydration and degassing by one-stage thin film distillation: the carnosic acid added with co-solvent was pumped steadily into the first-stage thin-film distillation column at a flow rate of 40ml / min for dehydration and degassing by one-stage thin-film distillation. The heating temperature is 90°C, the vacuum degree is 100-200Pa, the speed of the scraping film is 100rpm, and the discharge condensation temperature is 60°C;

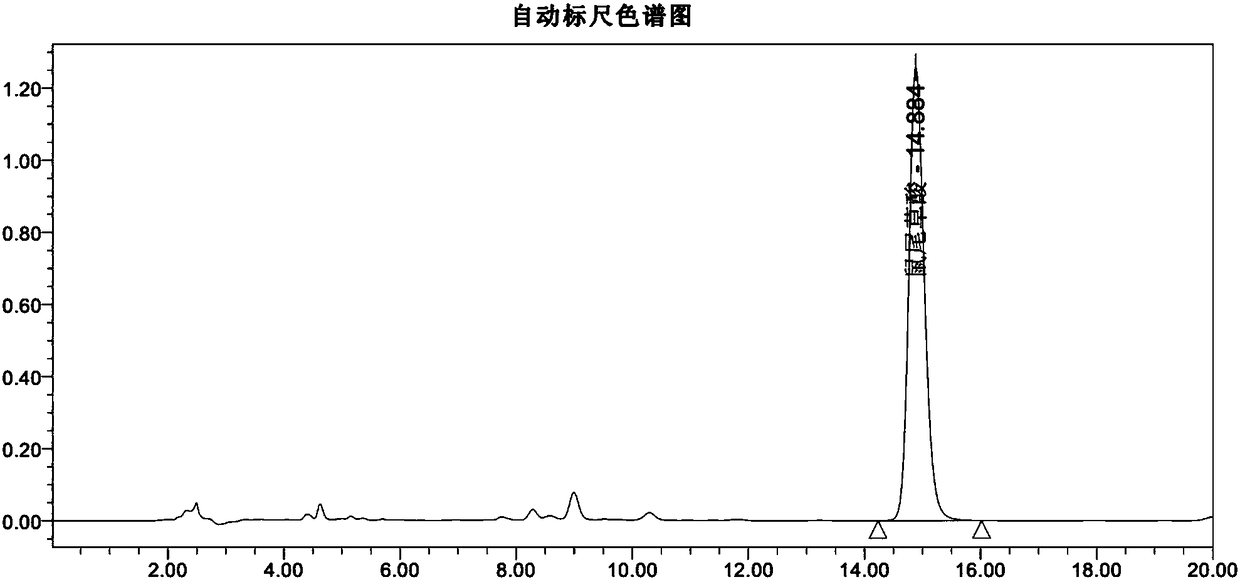

[0037] (3) Secondary molecular distillation separation: pump the dehydrated and degassed liquid into the secondary molecular distillation at a flow rate of 40ml / min for secondary molecular distillation separation to obtain 0.18kg of light c...

Embodiment 3

[0040] A method for purifying carnosic acid by molecular distillation, comprising the following steps:

[0041] (1) Carnosic acid solubilization: Take 1 kg of carnosic acid product with a content of 28% initially extracted by conventional methods, add 2 kg of glycerol and stir to dissolve at 65±2°C;

[0042] (2) Dehydration and degassing by one-stage thin film distillation: the carnosic acid added with co-solvent was pumped steadily into the first-stage thin-film distillation column at a flow rate of 40ml / min for dehydration and degassing by one-stage thin-film distillation. The heating temperature is 90°C, the vacuum degree is 100-200Pa, the speed of the scraping film is 100rpm, and the discharge condensation temperature is 60°C;

[0043] (3) Secondary molecular distillation separation: pump the dehydrated and degassed liquid into the secondary molecular distillation at a flow rate of 40ml / min for secondary molecular distillation separation to obtain 0.11kg of light component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com