Solidified heavy metal remover and preparation method

A technology for removing agents and heavy metals, which is applied in the field of contaminated soil treatment and restoration, to achieve low prices, restore removal effects, and facilitate recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

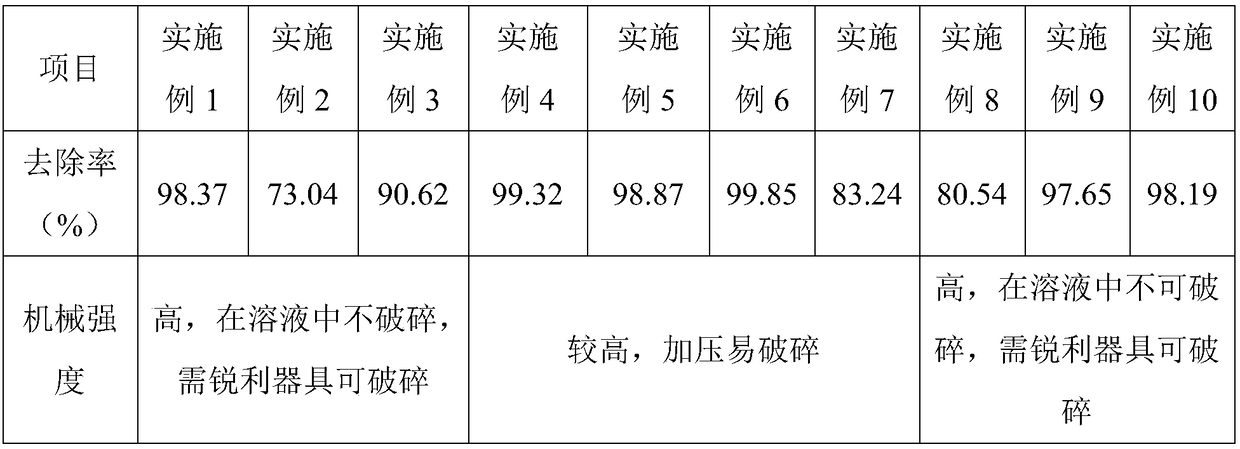

Examples

Embodiment 1

[0032] This embodiment provides a solidification type heavy metal remover, comprising the following components, the mass percent of each component is:

[0033] Adsorption active material is 20% of natural zeolite powder,

[0034] The pore forming agent is ammonium carbonate 0.5%,

[0035] The coagulant is Portland cement 79.5%.

[0036] Its preparation method is:

[0037] 1) Dissolve ammonium carbonate in deionized water to form an ammonium carbonate solution, then add natural zeolite powder and Portland cement to the mixed powder uniformly mixed according to the above mass percentage, knead and extrude into a 1cm diameter and height Cylinder particles, pour water every 12 hours at room temperature, let the cylinder particles solidify naturally for 10 days to achieve the required mechanical strength, and obtain ordinary solidified heavy metal remover;

[0038] 2), put the ordinary coagulation-type heavy metal remover obtained in step 1) in a 20% by volume hydrochloric acid ...

Embodiment 2

[0040] This embodiment provides a solidification type heavy metal remover, comprising the following components, the mass percent of each component is:

[0041] The adsorption active material is an active adsorption material rich in amino groups synthesized by silica powder and 3-aminopropyltriethoxysilane through hydrothermal synthesis method 20%

[0042] The pore forming agent is ammonium carbonate 0.5%,

[0043] The coagulant is Portland cement 79.5%.

[0044] Its preparation method is:

[0045] 1) Dissolving ammonium carbonate in deionized water to form an ammonium carbonate solution, and then adding it to silica powder and 3-aminopropyltriethoxysilane through hydrothermal synthesis of active adsorption materials rich in amino groups and silicon Salt cement is uniformly mixed according to the above mass percentage, kneaded and extruded into cylindrical particles with a diameter and height of 1cm, poured water every 12 hours at room temperature, and let the cylindrical par...

Embodiment 3

[0048] This embodiment provides a solidification type heavy metal remover, comprising the following components, the mass percent of each component is:

[0049] Adsorption active material is chitosan 2% and natural zeolite powder 16%,

[0050] The pore-forming agent is ammonium bicarbonate 2%,

[0051] The coagulant is Portland cement 80%.

[0052] Its preparation method is:

[0053] 1) Dissolve ammonium bicarbonate in deionized water to form ammonium bicarbonate solution, then add chitosan, natural zeolite powder and Portland cement to the mixed powder uniformly mixed according to the above mass percentage, knead and extrude into a diameter and cylindrical particles with a height of 1 cm, pour water every 12 hours at room temperature, let the cylindrical particles naturally solidify for 10 days to achieve the required mechanical strength, and obtain a common solidified heavy metal remover;

[0054] 2), put the ordinary coagulation-type heavy metal remover obtained in step 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com