Monovalent selective cation exchange membrane based on cross-linked quaternary polyaniline and preparation method of monovalent selective cation exchange membrane

A cation exchange membrane, polyaniline technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problem of lack of high-performance monovalent selective separation membrane, to ensure stability and selectivity, increase stability and The effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A commercial cation exchange membrane was used as the base membrane, and the commercial cation exchange membrane was purchased from Tokuyama Soda Co., Ltd., Japan, model CM-1.

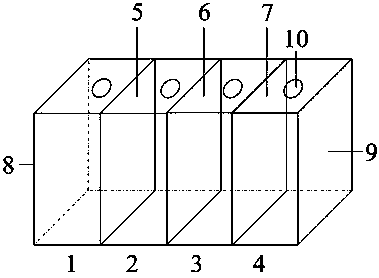

[0021] Soak the surface of the basement membrane with 1 mol / L aniline monomer solution for 60 minutes, take out the basement membrane and use filter paper to blot the excess solution on the surface, and then soak in 1 mol / L ferric chloride solution for 60 minutes, the aniline monomer is under the action of ferric chloride An oxidative polymerization reaction occurred on the surface of the base film to form a polyaniline active layer, which was then placed on a heater at 60°C to dry, and then the film was immersed in a 5 g / L 1,2-dibromoethane solution for 6 h ( The solvent of the 1,2-dibromoethane solution is ethanol), and finally the base membrane is taken out from the 1,2-dibromoethane solution and washed repeatedly with pure water to obtain a cross-linked quaternized polyaniline monovalent sele...

Embodiment 2

[0027] The steps in the above example 1 are unchanged, but the 1,2-dibromoethane solution is changed to the 1,4-dibromobutane solution. The flux of the sodium-magnesium ion of embodiment 2 modified membranes is , the selective permeation value of the cross-linked quaternized polyaniline monovalent selective cation exchange membrane product obtained in this example reaches 3.52. A better selectivity was obtained.

Embodiment 3

[0029] The steps in the above example 1 are unchanged, but the 1,2-dibromoethane solution is changed to the 1,6-dibromohexane solution. The flux of the sodium-magnesium ion of embodiment 3 modified membranes is ), the selective permeation value of the cross-linked quaternized polyaniline monovalent selective cation exchange membrane product obtained in this example reaches 3.31.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap