A double-carbon structure modified silicon-carbon composite negative electrode material and a preparation method thereof

A technology of carbon-silicon composite and negative electrode materials, applied in structural parts, battery electrodes, electrical components, etc., can solve the problems of low conductivity of silicon materials and lithium ion migration rate, poor stability, and inability to meet the application requirements of high power density equipment , to achieve the effect of favorable cycle stability, stable Coulombic efficiency, and increase of effective reaction interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

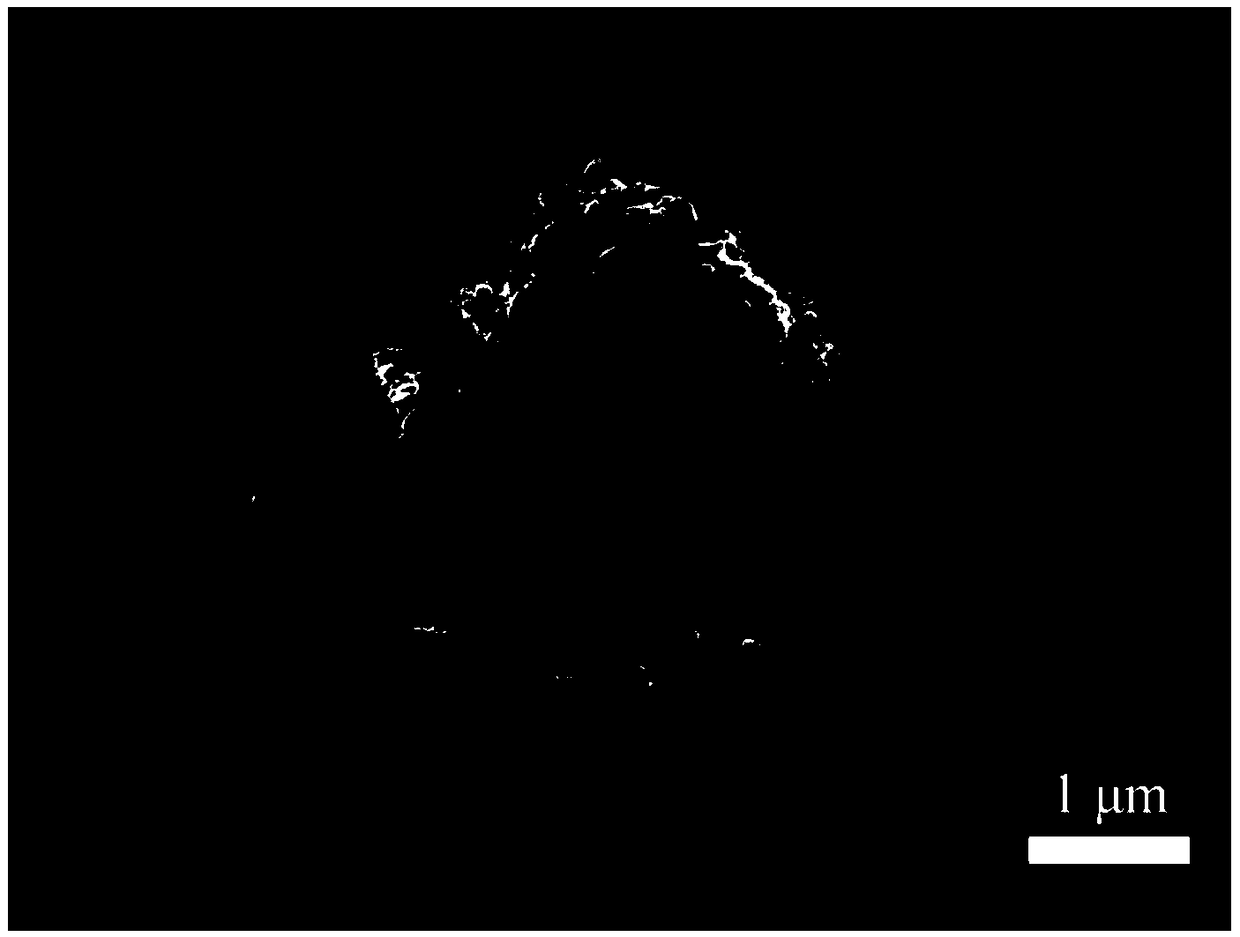

Image

Examples

Embodiment 1

[0037] (1) Disperse 300mg of silicon powder with a size of 100-120nm in an ethanol solution, and ultrasonicate for 2 hours to obtain a suspension; disperse 550mg of citric acid (CA) in an appropriate amount of ethanol solution to obtain a clear solution; add the silicon solution dropwise Enter the citric acid solution, stir at high speed, mix evenly, stir in a water bath at 65°C until all the solvent is evaporated; then raise the temperature to 270°C in a tube furnace under the protection of nitrogen, keep it for 4 hours, cool with the furnace, and grind to obtain Si@C(CA) material;

[0038] (2) Dissolve 150mg of polyacrylonitrile (PAN) in 5ml of dimethylformamide (DMF) solution, stir in an oil bath at 80°C for 2h; add 120mg of Si@C(CA) to the PAN / DMF mixed solution , ultrasonically for 2 hours to make it uniformly dispersed, and then placed on a magnetic stirrer to stir vigorously, and after 15 hours to form a uniformly mixed liquid; slowly add deionized water to the mixed so...

Embodiment 2

[0041] (1) Disperse 200mg of silicon powder with a size of 50-60nm in an ethanol solution, and ultrasonicate for 2 hours; disperse 300mg of citric acid (CA) in an appropriate amount of ethanol solution to obtain a clear solution; drop the silicon powder solution into citric acid In the solution, stir at a high speed, mix evenly, stir in a water bath at 70°C until all the solvent is evaporated; then raise the temperature to 250°C in a tube furnace under the protection of argon, keep it for 4 hours, cool with the furnace, and grind to obtain Si @C(CA)Material;

[0042] (2) Dissolve 150mg of polyacrylonitrile (PAN) in 5ml of dimethylformamide (DMF) solution, stir in an oil bath at 80°C for 2h; add 150mg of Si@C(CA) to the PAN / DMF mixed solution , ultrasonically for 2 hours to make it evenly dispersed, and then placed on a magnetic stirrer to stir vigorously, and a uniformly mixed liquid was formed after 16 hours; deionized water was slowly added dropwise to the mixed solution to ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com