Air cylinder and compressor

A cylinder and cylinder body technology, applied in the field of compressors, can solve the problem that the suction efficiency cannot be further improved, and achieve the effects of simplifying the design of the suction structure of the cylinder, facilitating the design, and reducing the eddy current phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

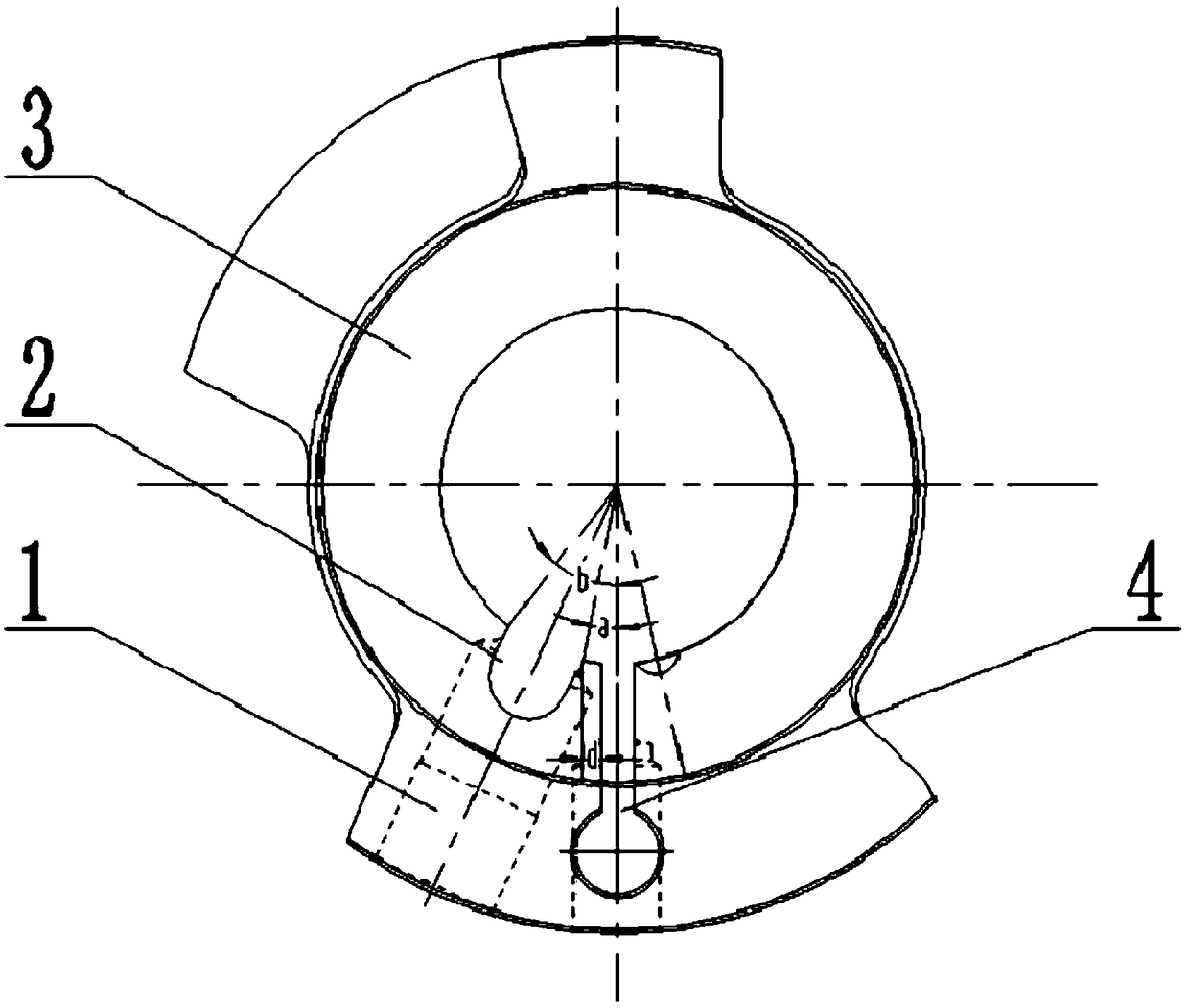

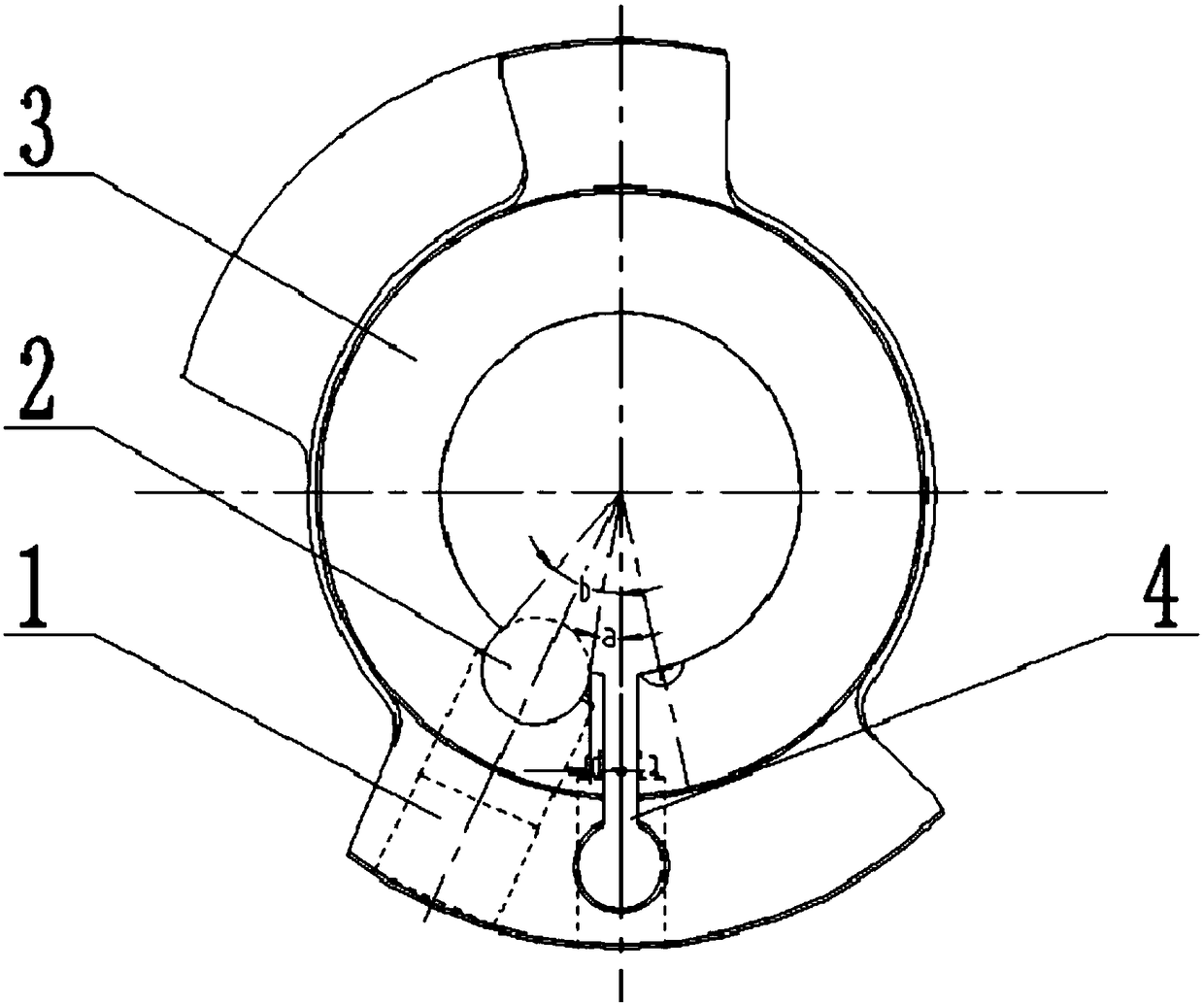

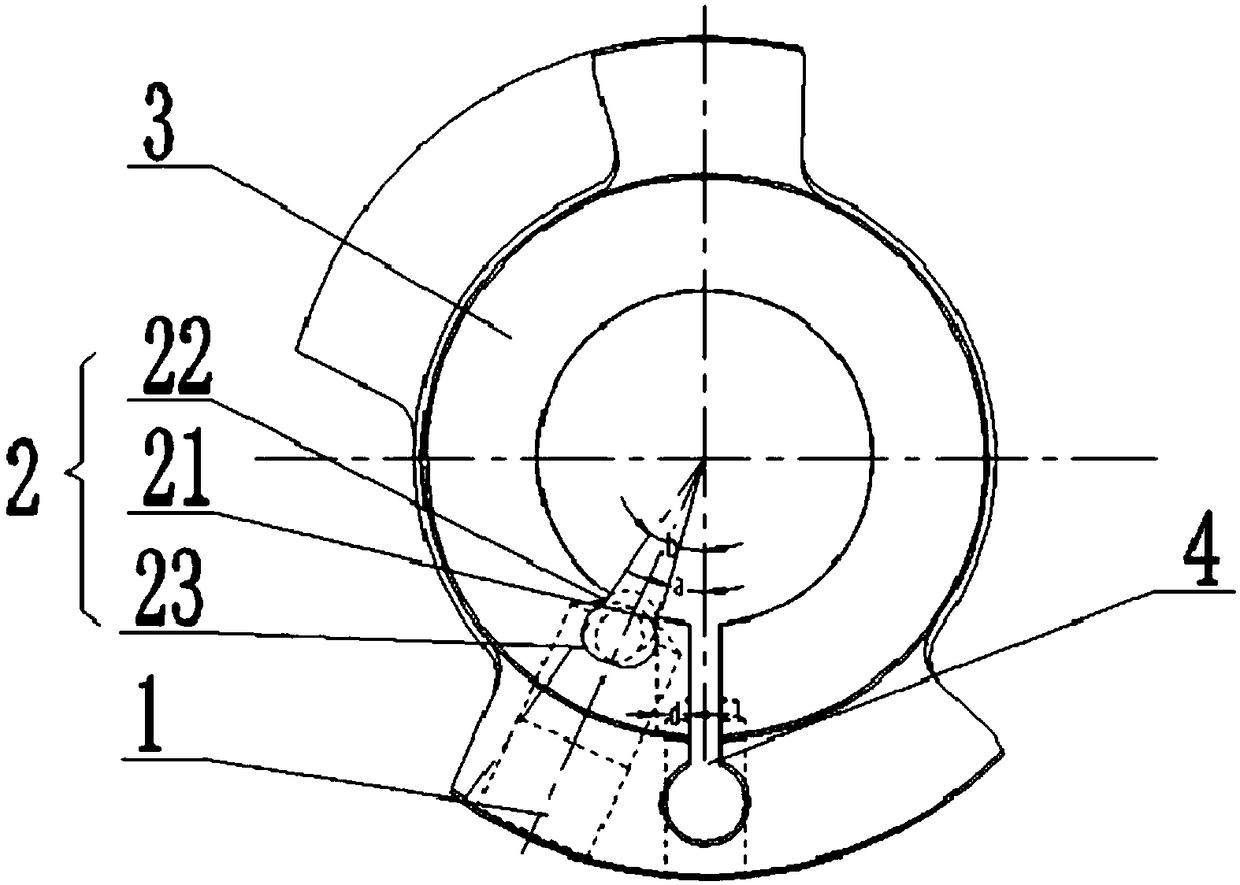

[0040] Such as image 3 As shown in -6, this embodiment provides a cylinder, which includes a cylinder body 3 , a slide groove 4 and an air suction port 2 arranged on the cylinder body 3 , and the air suction port 2 is arranged on one side of the slide groove 4 .

[0041] Such as image 3 As shown, the suction port 2 is arranged along the axial direction of the cylinder, and the inner wall of the cylinder body 3 located at the suction port 2 is also provided with a main suction port 1, and the main suction port 1 penetrates through the cylinder body 3 in the radial direction of the cylinder. The wall thickness is set, the first end of the main suction port 1 communicates with the outer peripheral surface of the cylinder body 3 , and the second end communicates with the suction port 2 .

[0042] Such as image 3 As shown, the section perpendicular to the central line of the cylinder is defined as the first section, and the cross section of the suction port 2 cut off by the fi...

Embodiment 2

[0055] The present invention provides a compressor having the above-mentioned cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com