A method for reinforcing a double-curved arch bridge with a corrugated arch plate

A double-curved arch bridge and arch-slab technology, which is applied in the field of corrugated arch-slab double-curved arch bridge reinforcement, can solve the problems of unfavorable force on the original bridge structure, increase the load of the original bridge body, and unfavorable structural force, etc., so as to ensure safety and durability, increase structural bearing capacity, and reduce self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

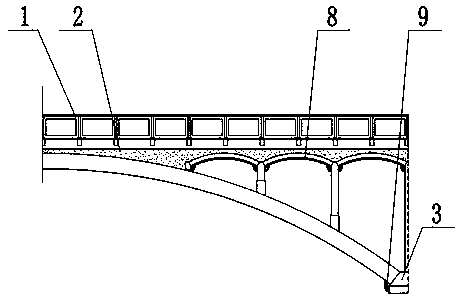

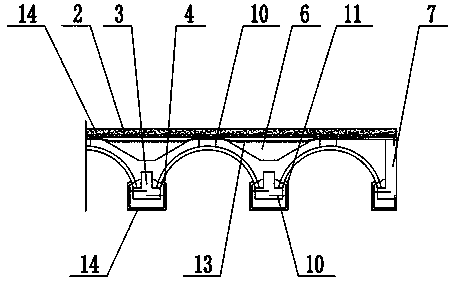

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0043] like figure 1 and figure 2 As shown, the invention discloses a method for strengthening a double-curved arch bridge with a corrugated arch plate, comprising the following steps:

[0044] (1) Remove the bridge deck guardrail, sidewalk slab and bridge deck pavement;

[0045] In the present invention, the bridge deck pavement includes road surfaces of motor vehicle lanes and non-motor vehicle lanes.

[0046] (2) Excavate the filler above the main arch ring of the solid section of the main arch ring and the filler above the abdominal arch ring of the hollow section of the main arch ring, and seal the cracks in the main arch ring;

[0047] Before processing, guardrails, sidewalk slabs, and bridge deck pavement need to be excavated, as well as fillers, so as to unload the original double-curved arch bridge, reduce the stress level of the original structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com