Preparation method of graphene composite protective layer for prebaked carbon anode

A graphene protective layer and graphene composite technology, which is applied in the field of new carbon anode materials, can solve the problems of reducing the service life of carbon blocks, adding a large amount of additives, and consuming carbon blocks, so as to eliminate the problem of shedding and block oxidation , Improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

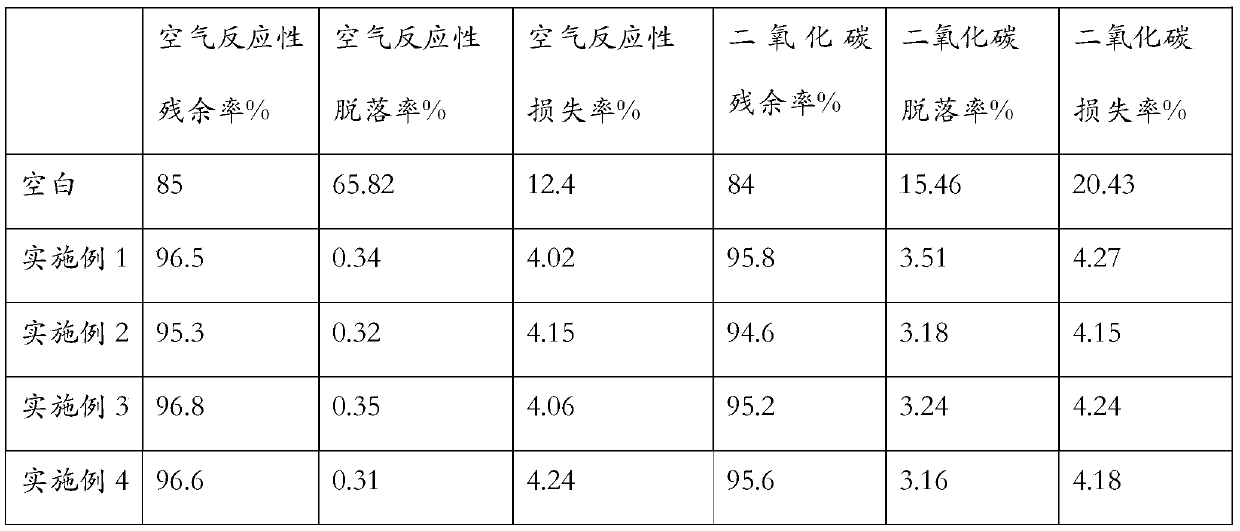

Embodiment 1

[0045] The preparation method of graphene protective layer for prebaked anode carbon block, its steps are as follows:

[0046] (1) Add 315g of distilled water into a 500ml three-necked bottle, start mechanical stirring, add 20g of graphene oxide, start ultrasonication, stir for 30min, add 15g of water-soluble phenolic resin, stir for 1hr, heat to 60°C, react for 12hr, stop heating and Stir to obtain the graphene phenolic water dispersion product;

[0047] (2) Take by weighing 100g graphene phenolic aqueous dispersion, add in the 500ml there-necked bottle, stir 30min, add 125g graphite powder aqueous emulsion (solid content 40%), stir 30min under ultrasonic, add 8g nano-alumina aqueous dispersion (solid content) Content 10%), ultrasonic stirring 8hr, stop ultrasonic and stirring, obtain graphene composite water-based coating;

[0048] (3) Weigh 50 grams of graphene composite water-based paint, add 50 g of distilled water to dilute, use a spray gun to spray on the surface of th...

Embodiment 2

[0051] The preparation method of graphene protective layer for prebaked anode carbon block comprises the following steps:

[0052] (1) Add graphene oxide while stirring in distilled water, then ultrasonically stir for 30 minutes, add water-soluble phenolic resin, heat to 60 ° C and stir, and carry out redox reaction. After 12 hours of reaction, stop heating and stirring to obtain graphene Aqueous dispersion of phenolic resin;

[0053] The weight ratio of graphene oxide and distilled water is: 1:21; The weight ratio of graphene oxide and phenolic resin is 2:1;

[0054] (2) get 140 parts of graphene phenolic resin aqueous dispersion in (1), add successively 100 parts of graphite powder emulsions, 8 parts of nano-alumina particles, ultrasonically stir 8h, obtain graphene composite coating;

[0055] The solid content in the graphite powder emulsion is 40%;

[0056] (3) Get 50 parts of the graphene composite coating in (2), add 60 parts of distilled water to dilute, adopt spray g...

Embodiment 3

[0060] The preparation method of graphene protective layer for prebaked anode carbon block comprises the following steps:

[0061] (1) Add graphene oxide while stirring in distilled water, then ultrasonically stir for 30 minutes, add water-soluble phenolic resin, heat to 60 ° C and stir, and carry out redox reaction. After 12 hours of reaction, stop heating and stirring to obtain graphene Aqueous dispersion of phenolic resin;

[0062] The weight ratio of graphene oxide and distilled water is: 4:65, and the weight ratio of graphene and phenolic resin is 2:3;

[0063] (2) get 140 parts of graphene phenolic resin aqueous dispersion in (1), add successively 120 parts of graphite powder emulsions, 8 parts of aluminum powder dispersions, ultrasonically stir 8h, obtain graphene composite coating;

[0064] The solids content in the graphite powder emulsion is 40%, and the solids content in the aluminum powder dispersion is 10%;

[0065] (3) Get 50 parts of the graphene composite coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com