A viscosity-reducing oil displacement agent and oil displacement system suitable for heavy oil reservoirs

A technology of viscous oil displacement agent for heavy oil reservoirs, which is applied in the direction of drilling compositions, chemical instruments and methods, etc. It can solve the problems of poor anti-calcium and magnesium ions, large amount of surfactants, limitations, etc., and achieve improvement Oil displacement efficiency, good salt resistance, and the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment. However, the scope of the present invention is not limited to the following examples. Those skilled in the art can understand that various changes and modifications can be made in the present invention without departing from the spirit and scope of the present invention.

[0024] The instruments, reagents, materials, etc. involved in the following examples, unless otherwise specified, are conventional instruments, reagents, materials, etc. in the prior art, and can be obtained through formal commercial channels. The experimental methods, detection methods, etc. involved in the following examples, unless otherwise specified, are conventional experimental methods, detection methods, etc. in the prior art.

[0025] Embodiment Viscosity-reducing oil displacement agent and its application

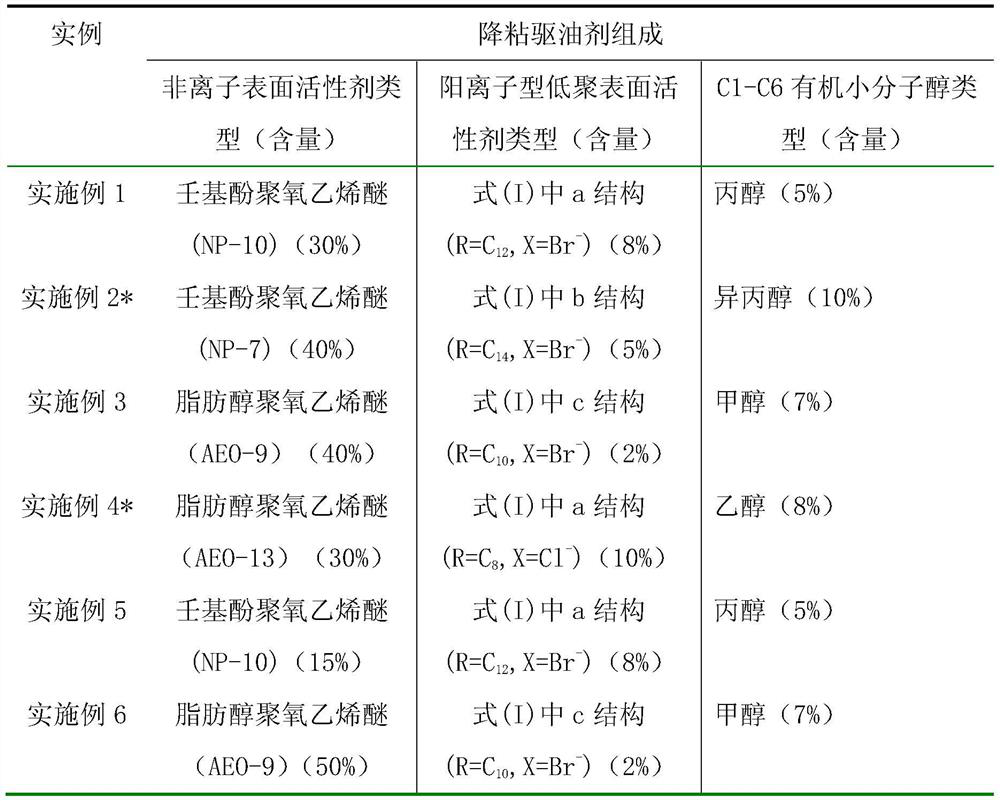

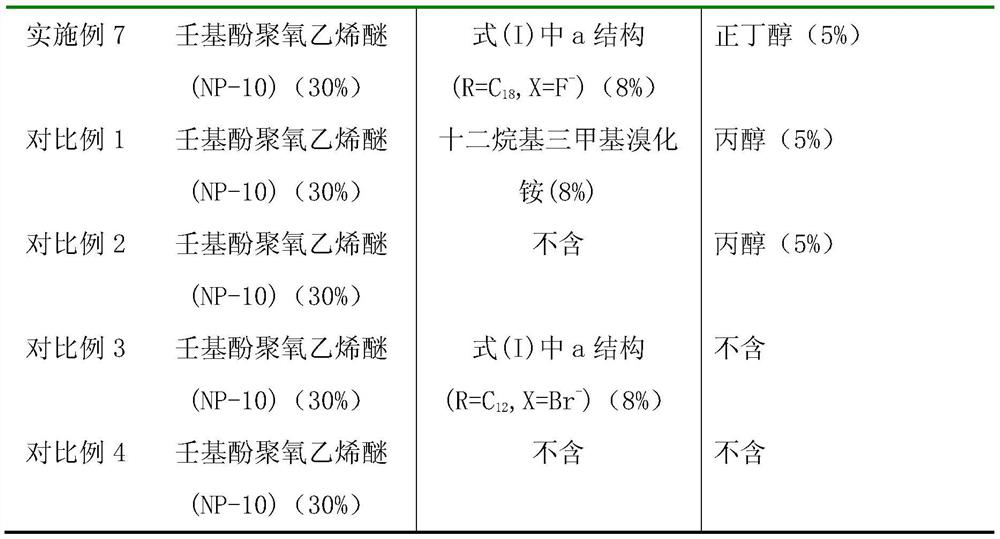

[0026] The nonionic surfactant, cationic oligomeric surfactant, C 1 ~C 6 The organic small molecu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com