Novel polymer self-adhesive waterproof coiled material and preparation method thereof

A waterproof membrane, polymer technology, applied in the direction of adhesive, film/sheet adhesive, pressure-sensitive film/sheet, etc. Physical and mechanical properties, easy to use, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

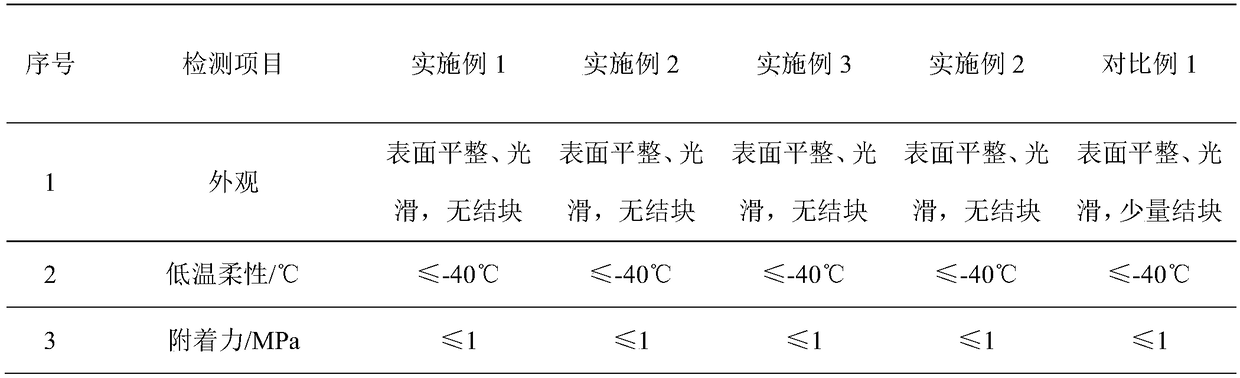

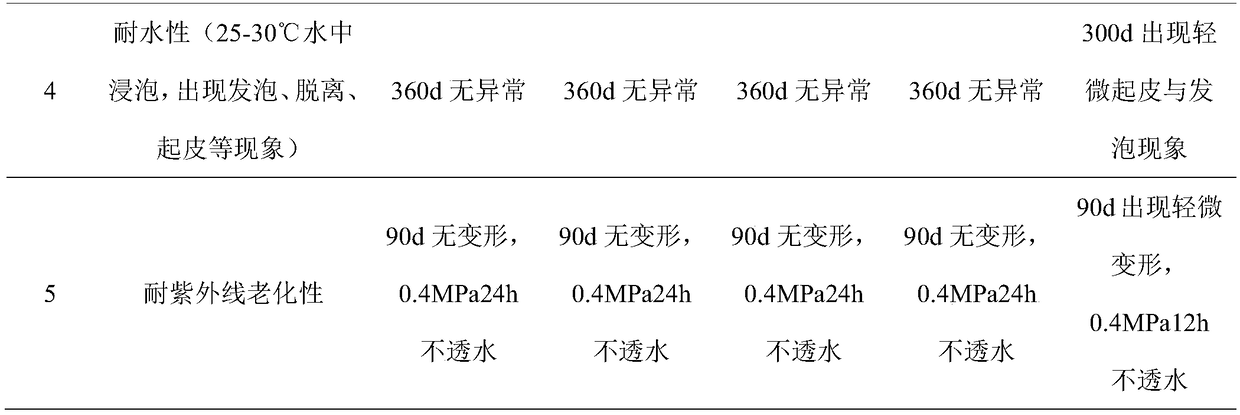

Embodiment 1

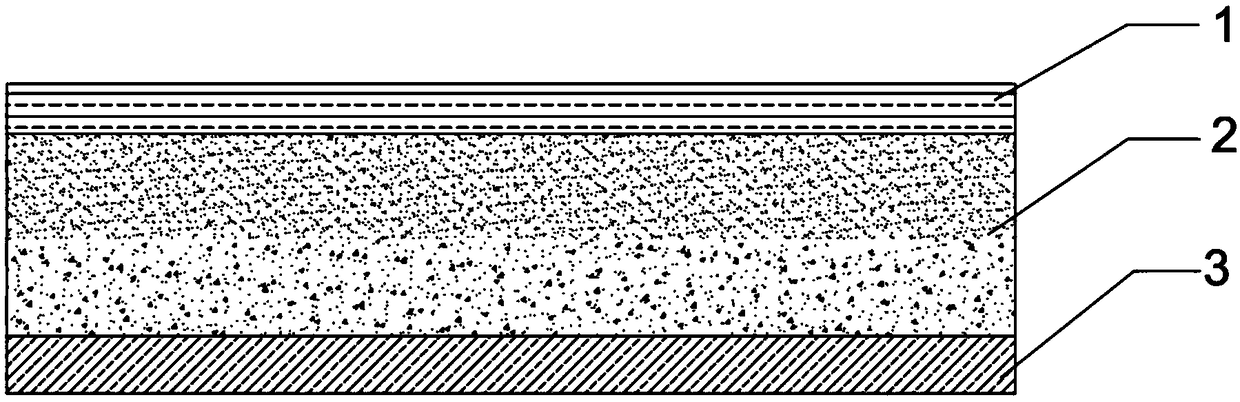

[0024] A new polymer self-adhesive waterproof membrane:

[0025] (1) Raw materials: 1) Base material for waterproof layer: Component A: 6 parts of styrene, 9.76 parts of butyl acrylate, 4 parts of octyl acrylate, 0.2 parts of emulsifier, 0.04 parts of initiator and 20 parts of water; component B : 18 parts of heavy calcium powder, 12.6 parts of light calcium powder, 3.6 parts of kaolin, 6.3 parts of titanium dioxide, 1.8 parts of mica, 2.07 parts of quartz sand, 0.225 parts of antioxidant, 0.135 parts of dispersant, 0.09 part of antistatic agent, antistatic agent 0.045 parts of fuel, 0.09 parts of auxiliary agent (in this example, the auxiliary agent is a defoamer, and the defoamer is selected from silicone oil) and 0.045 part of pigment; 15 parts of water;

[0026] 2) Base material: polyester non-woven fabric;

[0027] 3) Adhesive layer: strong pressure-sensitive adhesive;

[0028] 4) Anti-adhesive film: polyester film;

[0029] (2) Preparation method: 1) Preparation of wa...

Embodiment 2

[0033] A new polymer self-adhesive waterproof membrane:

[0034](1) Raw materials: 1) Base material for waterproof layer: Component A: 7.98 parts of styrene, 10.5 parts of butyl acrylate, 3.016 parts of octyl acrylate, 0.42 parts of emulsifier, 0.084 parts of initiator and 20 parts of water; component B : 19.35 parts of heavy calcium powder, 11.051 parts of light calcium powder, 2.15 parts of kaolin, 5.16 parts of titanium dioxide, 2.15 parts of mica, 2.15 parts of quartz sand, 0.258 parts of antioxidant, 0.172 parts of dispersant, 0.129 parts of antistatic agent, 0.086 part of combustion agent, auxiliary agent (in this example, auxiliary agent is the mixture of accelerator and leveling agent, wherein accelerator is selected water-based acrylic resin and leveling agent is selected polydimethylsiloxane for use) 0.129 part and pigment 0.215 part; 15 parts of water;

[0035] 2) Substrate: glass fiber cloth;

[0036] 3) Adhesive layer: strong pressure-sensitive adhesive;

[003...

Embodiment 3

[0042] A new polymer self-adhesive waterproof membrane:

[0043] (1) Raw materials: 1) Base material for waterproof layer: Component A: 8.815 parts of styrene, 10.75 parts of butyl acrylate, 2.58 parts of octyl acrylate, 0.946 parts of emulsifier, 0.129 parts of initiator and 19.78 parts of water; component B : 21 parts of heavy calcium powder, 8.568 parts of light calcium powder, 2.52 parts of kaolin, 5.46 parts of titanium dioxide, 1.26 parts of mica, 1.26 parts of quartz sand, 0.336 parts of antioxidant, 0.252 parts of dispersant, 0.168 parts of antistatic agent, antistatic agent Fuel agent 0.168 part, auxiliary agent (in this example, auxiliary agent is the mixture of defoamer, bactericide and thickener, wherein defoamer selects mineral oil for use, bactericide selects isothiazolinone for use and thickener selects water-based acrylic thickener for use Thickener) 0.168 parts and pigment 0.84 parts; Water 15 parts;

[0044] 2) Base material: polyester non-woven fabric;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com