Method for preparing modified phenolic resin adhesive from camellia oleifera cakes

A technology of phenolic resin glue and camellia cake, which is applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problem of many residual toxic components, poor viscosity control, low bonding strength, etc. problem, to achieve the effect of improving storage stability, low production cost and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

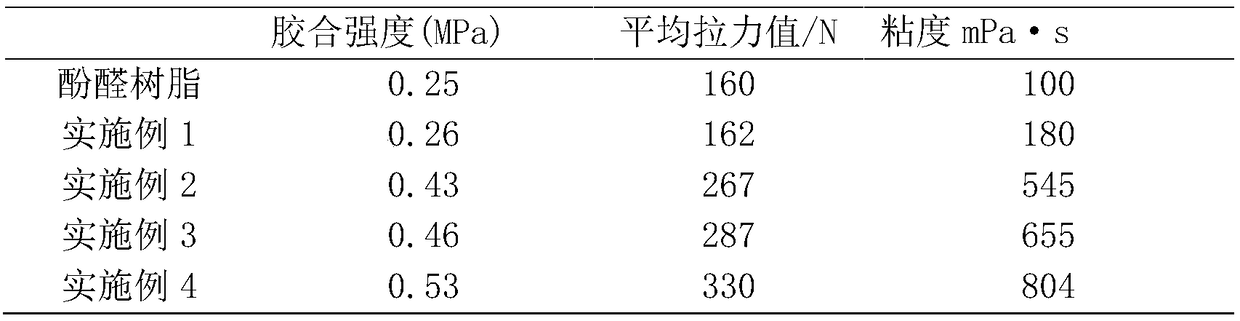

Examples

Embodiment 1

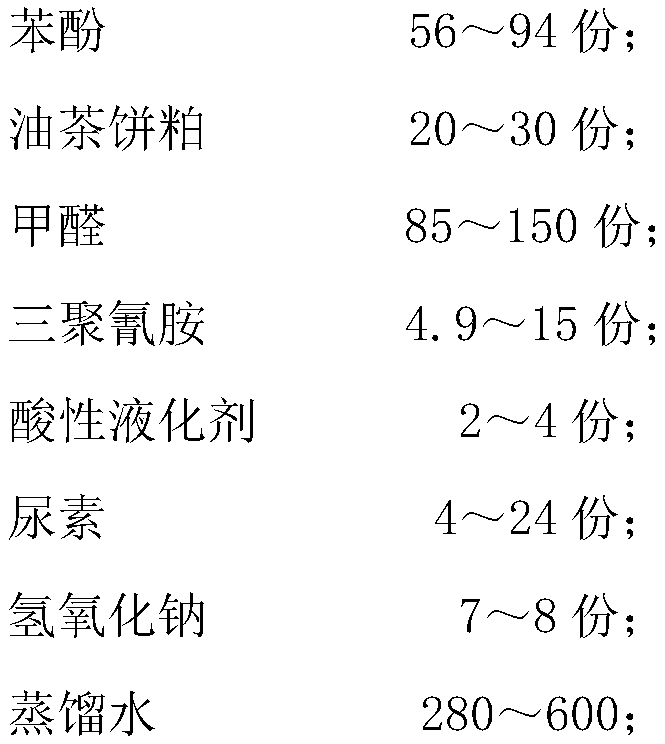

[0020] The first step, the preparation of liquefied camellia cake: weigh 30g camellia cake, 3.3g acidic liquefier, 24g urea and 210g distilled water in a three-necked round-bottomed flask, react at a water bath temperature of 90℃ for 2.0h and stop heating. When placed in a room and cooled to 60℃, the material is discharged, it is liquefied oil tea cake;

[0021] In the second step, 56g of phenol, 4.8g of sodium hydroxide, 5g of melamine, and 90g of distilled water were added to the above three-necked round-bottomed flask, and reacted in a water bath at 45℃ for 20min; after that, the temperature was adjusted to 55℃ and added in an average of three times. 20g formaldehyde, the reaction time is 50min; then continue to increase the temperature to 70℃, add 40g formaldehyde and 2.4g sodium hydroxide, continue for 20min, then heat up to 90℃, take out after reacting for 35min and continue stirring, when the temperature reaches 40℃ The material is the modified phenolic resin adhesive.

[0...

Embodiment 2

[0024] The first step is the preparation of liquefied camellia cake: weigh 20g camellia cake, 3.3g acidic liquefier, 8g urea and 420g distilled water in a three-necked round-bottom flask, react at a water bath temperature of 90°C for 2.0h and stop heating. When placed in the room and cooled to 60℃, the material is discharged, it is liquefied oil tea cake;

[0025] In the second step, 94g of phenol, 4.9g of sodium hydroxide, 15g of melamine, and 180g of distilled water were added to the above three-necked round bottom flask, and reacted in a water bath at 45°C for 20 minutes; then the temperature was adjusted to 55°C, and 30g was added every three times. Formaldehyde (addition), the reaction time is 50min; then continue to increase the temperature to 70℃, add 38.5g formaldehyde and 2.1g sodium hydroxide, continue for 20min, then heat up to 90℃, react for 30min, take out and continue stirring, when the temperature reaches 40℃ It can be discharged, which is the modified phenolic res...

Embodiment 3

[0028] The first step, the preparation of liquefied camellia cake: weigh 25g camellia cake, 3.3g acidic liquefier, 18g urea and 350g distilled water in a three-necked round-bottom flask, react at a water bath temperature of 90°C for 2.0h and then stop heating. When placed in a room and cooled to 60℃, the material is discharged, it is liquefied oil tea cake;

[0029] In the second step, 70g of phenol, 5.6g of sodium hydroxide, 10g of melamine, and 150g of distilled water were added to the above three-necked round bottom flask, and reacted in a water bath at 45°C for 20 minutes; then the temperature was adjusted to 55°C, and the addition was divided into three times each time. 25g formaldehyde, the reaction time is 50min; then continue to increase the temperature to 70℃, add 32g formaldehyde and 2.4g sodium hydroxide, continue for 20min, then increase the temperature to 90℃, react for 25min, take it out and continue stirring, when the temperature reaches 40℃, it can be discharged ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com