Gangue comprehensive integrated utilization method

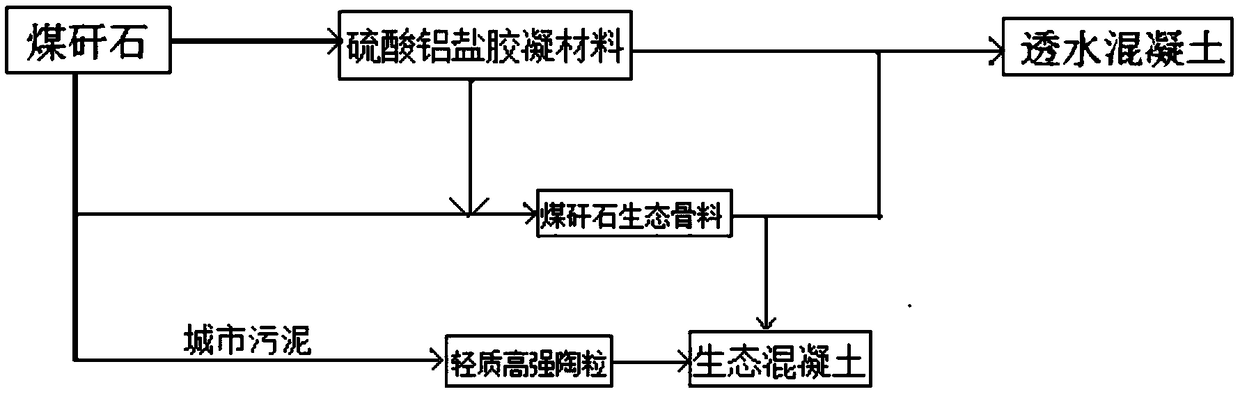

A technology for coal gangue and desulfurization gypsum is applied in the application field of coal gangue, which can solve the problems of single utilization route, lack of systematic utilization method of coal gangue, low product added value, etc., and achieves the effect of high added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] In step (1), the preparation method of described gelling material comprises the steps:

[0072] 1) First crush the large pieces of coal gangue, then screen out the coal gangue with a particle size greater than 25mm and less than 5mm, and leave the coal gangue with a particle size of 5-25mm for later use;

[0073] 2) Coal gangue with a size greater than 25 mm and a size less than 5 mm that are sieved together with desulfurized gypsum, aluminum ash, and electroslag are ground, mixed evenly, and then calcined to obtain the sulphoaluminate cementitious material.

[0074] The ratio of the coal gangue, desulfurized gypsum, aluminum ash and carbide slag is (mass percentage) 20%:20%:30%:30%.

[0075] In the preparation method of the gelling material, the low-temperature calcination temperature is 1250° C., and the time is 2 hours.

[0076] In step (2), the method for preparing light-weight high-strength ceramsite is as follows: by mass percentage, take 90% of coal gangue with ...

Embodiment 2

[0088] In step (1), the preparation method of described gelling material comprises the steps:

[0089] 1) First crush the large pieces of coal gangue, then screen out the coal gangue with a particle size greater than 25mm and less than 5mm, and leave the coal gangue with a particle size of 5-25mm for later use;

[0090] 2) Coal gangue with a size greater than 25 mm and a size less than 5 mm that are sieved together with desulfurized gypsum, aluminum ash, and electroslag are ground, mixed evenly, and then calcined to obtain the sulphoaluminate cementitious material.

[0091] In the preparation method of the cementitious material, the ratio of coal gangue, desulfurized gypsum, aluminum ash, and carbide slag is (mass percentage): 20%:20%:20%:40%

[0092] In the preparation method of the gelling material, the low-temperature calcination temperature is 1200° C., and the time is 3 hours.

[0093] In step (2), the method for preparing light-weight high-strength ceramsite is as follo...

Embodiment 3

[0105] In step (1), the preparation method of described gelling material comprises the steps:

[0106] 1) First crush the large pieces of coal gangue, then screen out the coal gangue with a particle size greater than 25mm and less than 5mm, and leave the coal gangue with a particle size of 5-25mm for later use;

[0107] 2) Coal gangue with a size greater than 25 mm and a size less than 5 mm that are sieved together with desulfurized gypsum, aluminum ash, and electroslag are ground, mixed evenly, and then calcined to obtain the sulphoaluminate cementitious material.

[0108] In the preparation method of the cementitious material, the proportions of coal gangue, desulfurized gypsum, aluminum ash and carbide slag are (mass percentage): 30%:20%:20%:30%.

[0109] In the preparation method of the gelling material, the low-temperature calcination temperature is 1300° C., and the time is 1 h.

[0110] In step (2), the method for preparing light-weight high-strength ceramsite is as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com