Anaerobic reaction tank

An anaerobic reaction tank and tank body technology, applied in anaerobic digestion treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. The volume of the pre-acidification pool and other issues can be improved to improve the reaction effect of wastewater, to operate quickly, and to reduce the clogging rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

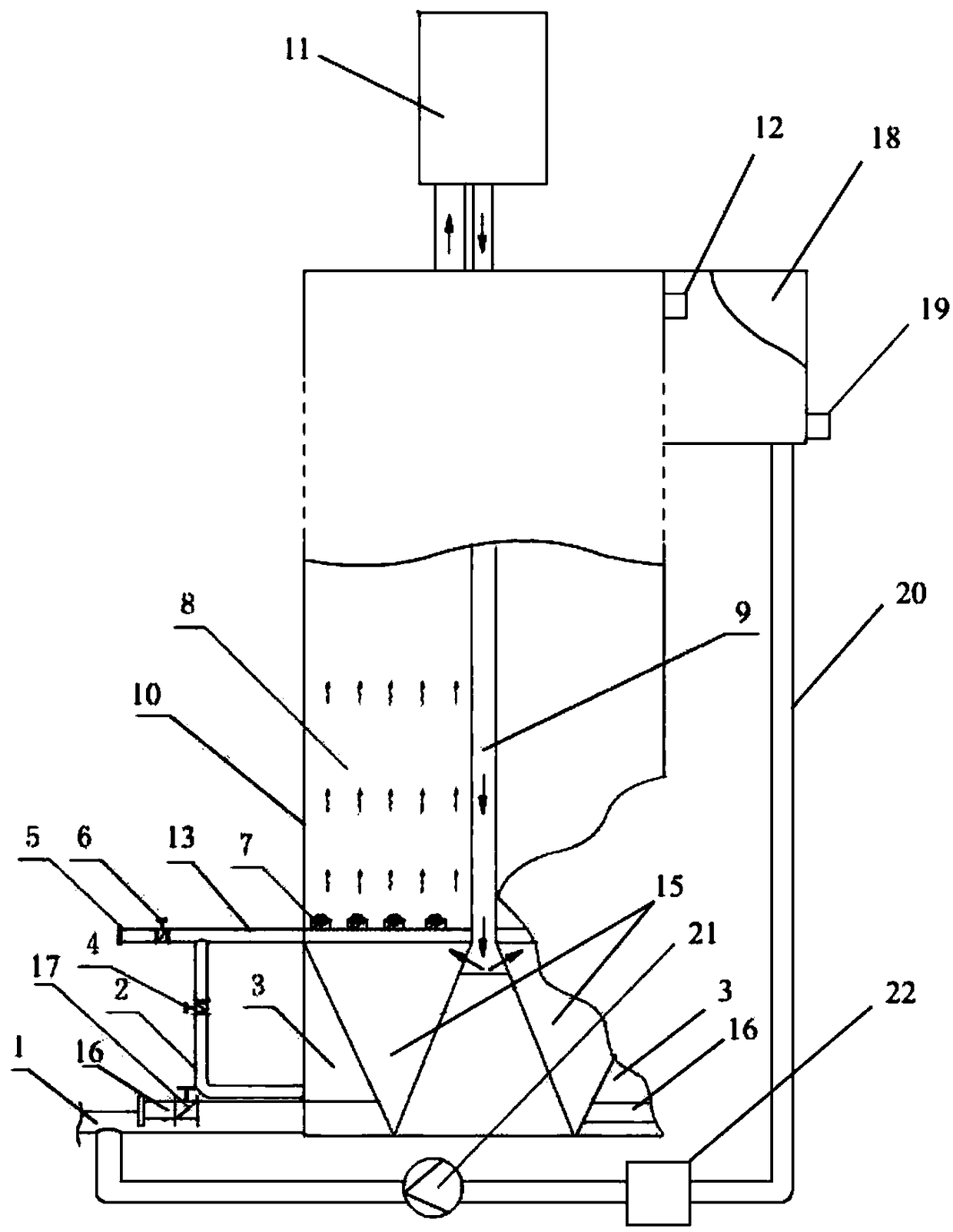

[0030] Such as figure 1 As shown, a kind of anaerobic reaction tank, comprises tank body 10, and the lower part of described tank body 10 is distributed with the dividing plate that longitudinal section is nearly " W " shape, and this dividing plate divides the lower part of described tank body 10 into a circle The water inlet distribution chamber 3 and a circle of sand collection chamber 15; the water inlet distribution chamber 3 is connected with the main water inlet pipe 1; the water inlet distribution chamber 3 is also connected with ten water inlet distribution pipes 2, of course, the water inlet The number of pipes 2 is not limited thereto, and can be selectively distributed according to needs. The water inlet distribution pipe 2 is evenly distributed around the outer circumference of the water inlet distribution chamber 3; the water inlet distribution pipe 2 is also combined with positive flushing Valve 4; ten water distribution branch pipes 13 are also distributed on t...

specific Embodiment 2

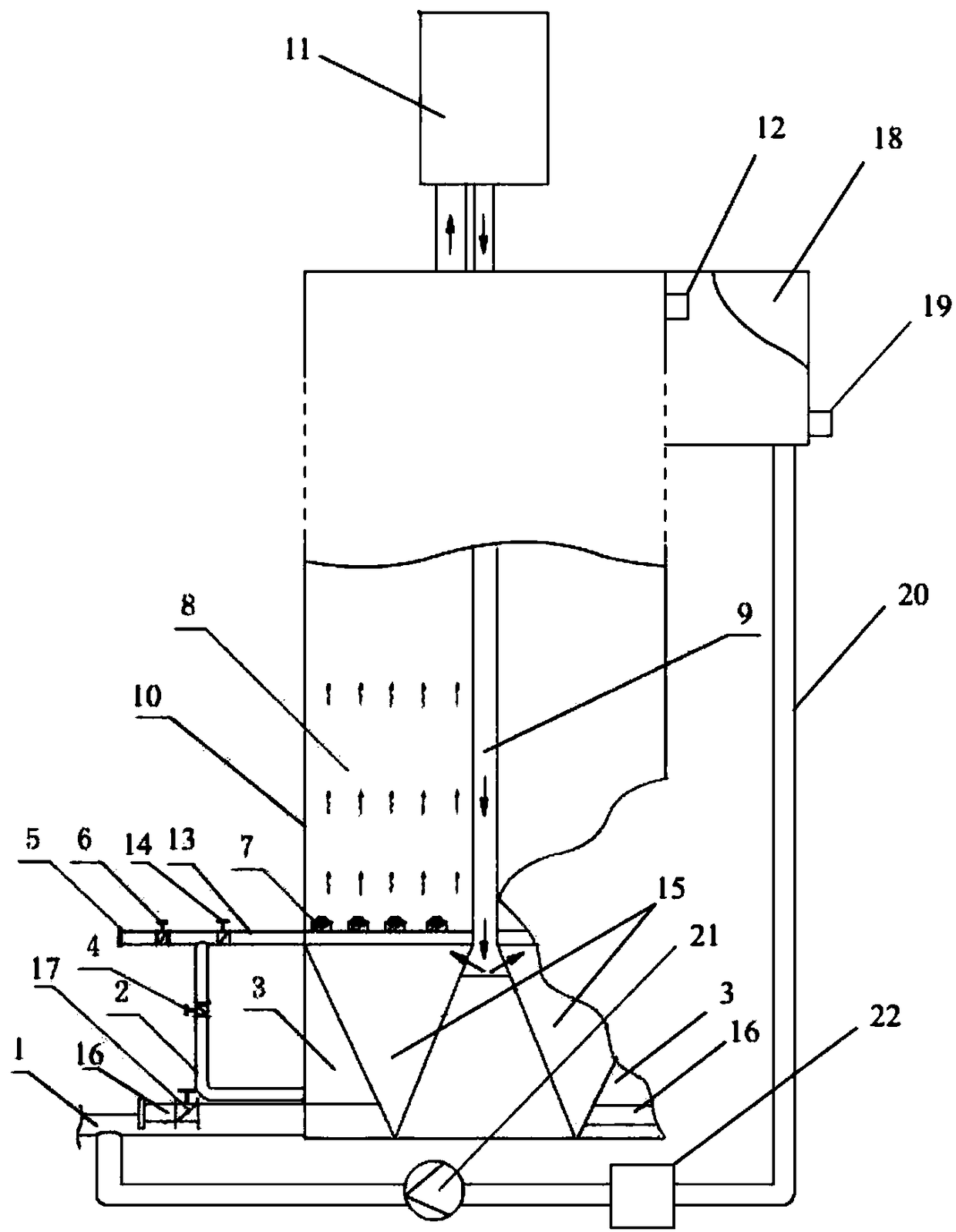

[0032] The difference between this embodiment and the specific embodiment only lies in: figure 2 As shown, the water distribution branch pipe 13 is also provided with a secondary valve 14, and the secondary valve 14 is distributed on the side of the tank where the water inlet distribution pipe 2 and the water distribution branch pipe 13 are connected. The secondary valve 14 is mainly used for finding and dredging blocked pipelines, and its function is as described in the beneficial effects of the present invention compared with the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com