Method for preparing two-dimensional near-monolayer montmorillonite

A montmorillonite and single-layer technology, which is applied in the field of preparing two-dimensional near-monolayer montmorillonite, can solve the problems of refractory biodegradation, adverse effects of water environment or groundwater environment, etc., and achieve the effect of good repeatability and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

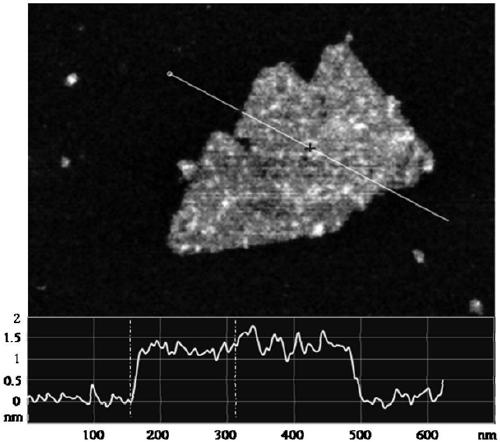

[0019] Add 1 gram of powdered sodium montmorillonite to 100 ml of pure water, and stir at a controlled speed of 200 rpm for 45 minutes to obtain a uniformly mixed montmorillonite suspension; place the probe of the ultrasonic breaker in the uniform solution, and ultrasonicate for 30 Minutes, then centrifuge the sonicated montmorillonite suspension at 8000rpm for 10 minutes, and take the upper suspension. Then freeze-dry the upper suspension to obtain a solid two-dimensional near-single-layer montmorillonite, which is the product. The product is a nearly monolayer montmorillonite with an average particle size of 230 nm and an average thickness of 2.5 nm. Its AFM image is as follows figure 1 shown. It can be seen from the figure that the obtained two-dimensional montmorillonite product is a uniform sheet with a thickness of about 1.5 nanometers.

Embodiment 2

[0021] Add 1 gram of powdered sodium montmorillonite to 100 ml of pure water, and stir at a controlled speed of 200 rpm for 120 minutes to obtain a uniformly mixed montmorillonite suspension; place the probe of the ultrasonic breaker in the uniform solution, and ultrasonically Minutes, then centrifuge the sonicated montmorillonite suspension at 8000rpm for 10 minutes, and take the upper suspension. Then freeze-dry the upper suspension to obtain a solid two-dimensional near-single-layer montmorillonite, which is the product. The product is nearly monolayer montmorillonite, with an average particle size of 230 nanometers and an average thickness of 2.5 nanometers.

Embodiment 3

[0023] Add 1 gram of powdered sodium montmorillonite to 100 ml of pure water, and stir at a controlled speed of 200 rpm for 45 minutes to obtain a uniformly mixed montmorillonite suspension; , continuously stirred for 3 days, then centrifuged the stirred montmorillonite suspension at 8000rpm for 10 minutes, and took the upper suspension; finally, freeze-dried the upper suspension to obtain a solid two-dimensional near monolayer montmorillonite, namely product. The product is nearly monolayer montmorillonite, with an average particle size of 230 nanometers and an average thickness of 2.5 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com