Glass multi-sided edging machine

A kind of edging machine and multi-edge technology, which is applied to the parts of grinding machine tools, machine tools and grinding machines suitable for grinding the edge of workpieces, etc. Quality and other issues, to achieve the effect of convenient operation, simple structure, convenient and fast handling and movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

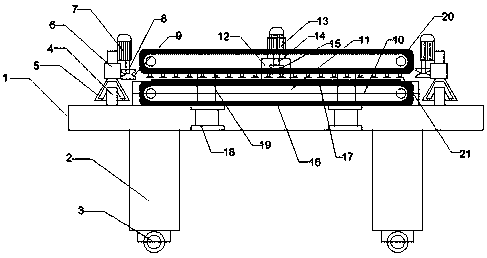

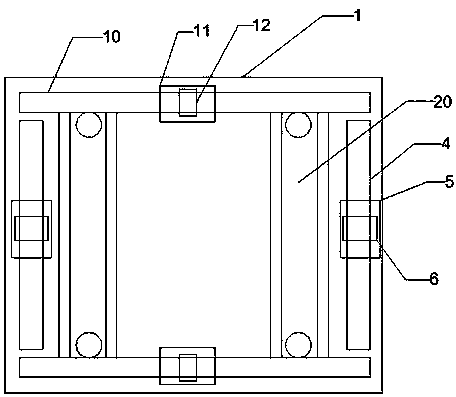

[0017] Such as figure 1 and figure 2 A glass polygonal edging machine shown includes a workbench 1, a support frame 2 is arranged under the workbench 1, a universal wheel 3 is arranged under the support frame 2, and first Slide rail 4, the first slide block 5 is set on the first slide rail 4, the first lifting device 6 is set on the first slide block 5, the first motor 7 is set on the first lifting device 6, on the first The first output shaft 8 is set under the motor 7, the first multi-faceted edging block 9 is set under the first output shaft 8, and the second slide rail 10 is respectively set on the front and rear sides of the workbench 1, and the second slide rail 10 The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com