Stainless steel-carbon steel composite plate hot continuous rolling large-scale preparing method

A composite plate and stainless steel technology, which is applied in the field of large-scale preparation of stainless steel-carbon steel composite plate hot rolling, can solve the problems of high energy consumption, affecting the effect of vacuuming, and poor plate shape, so as to reduce the impurity content and ensure the quality , the effect of preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

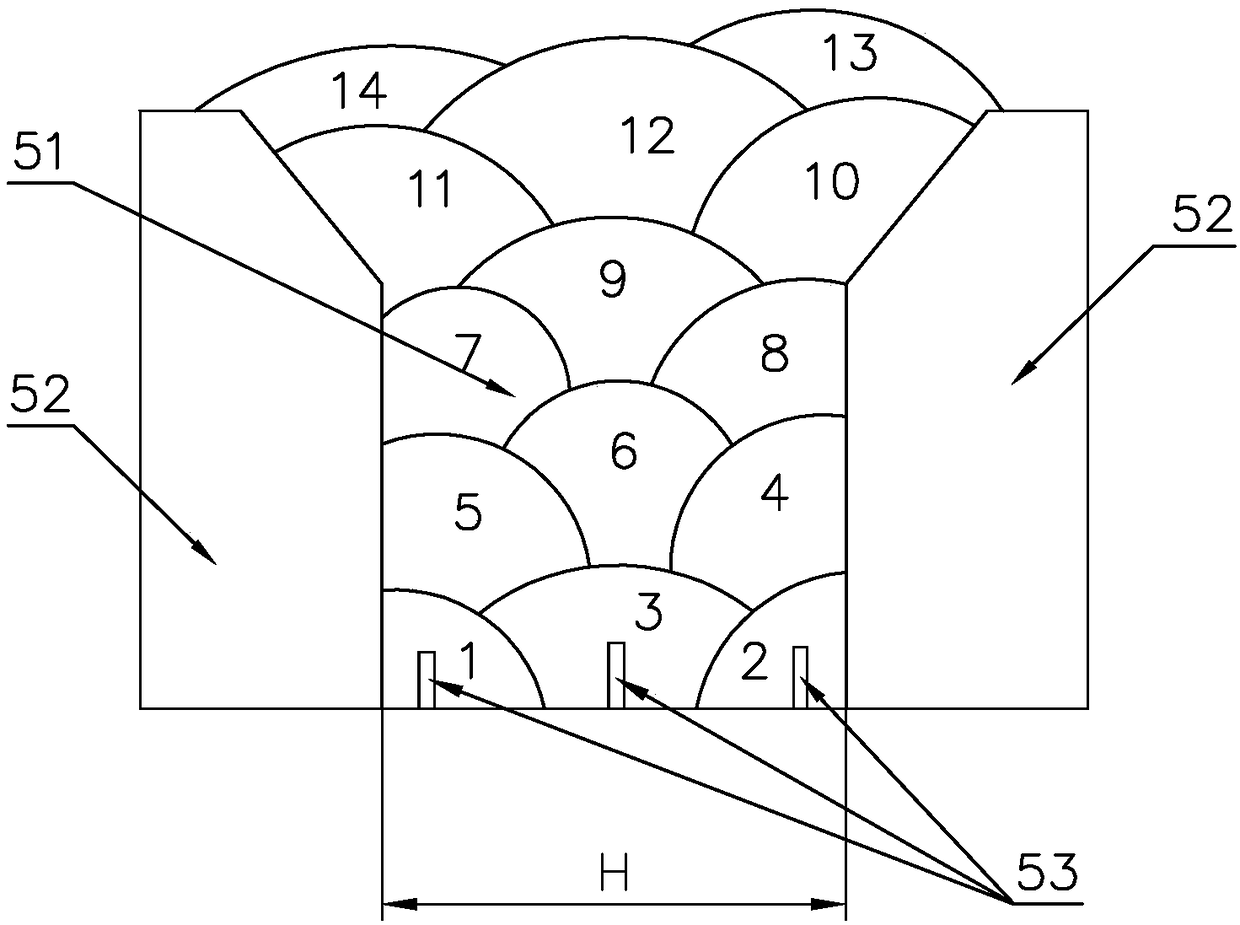

Embodiment 1

[0057] A large-scale production method of stainless steel-carbon steel composite plate hot rolling, including a base plate 51 and a cover plate 52, the base plate 51 is Q345 low-carbon steel, and the cover plate 52 is 304 stainless steel, wherein the size of the cover plate 52 is 10000mm× 1250mm×20mm, the size of the substrate 51 is 10000mm×1250mm×180mm, and its preparation method includes the following steps:

[0058] 1) Substrate and cladding surface treatment

[0059] Grinding and polishing of the surface of the substrate 51: remove the oxide skin on the processed surface of the substrate 51 to produce a metallic luster, and eliminate defects such as cracks, deep pits, and burrs. The angle grinder cleans the oil on the surface of the substrate 51;

[0060] Surface polishing of the cladding plate 52: use a polishing sheet to polish the surface of the cladding plate 52, clean the dust on the surface of the cladding plate 52, and then turn the plate to polish the other side o...

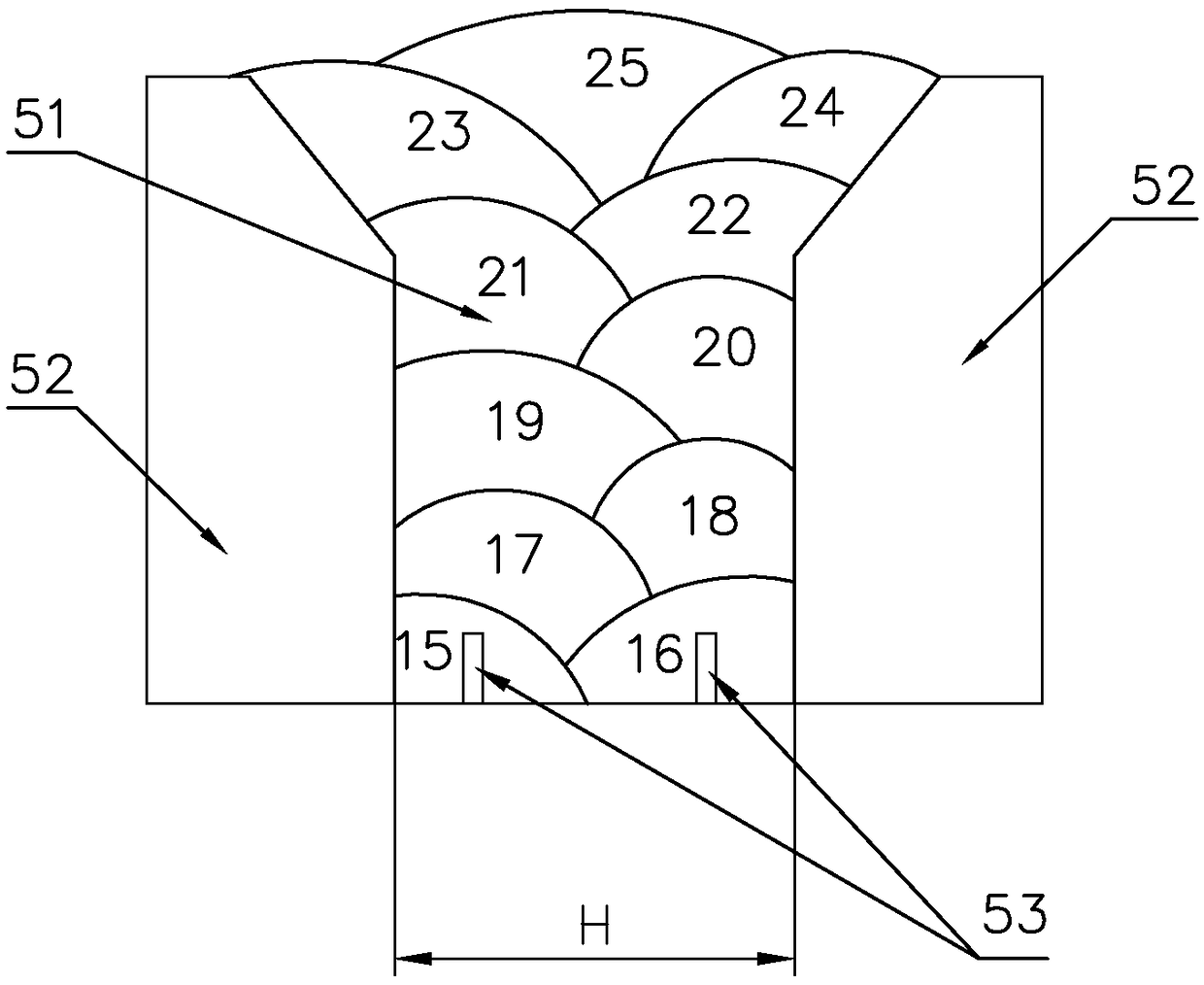

Embodiment 2

[0092] The difference from Example 1 is: the thickness of the base plate is 175mm, the thickness of the cladding plate is 25mm, the total reduction rate is 77.5%, the specification of the composite plate after rolling is 44000mm×1250mm×45mm, and the composite plate after forming is sheared The strength is 526MPa;

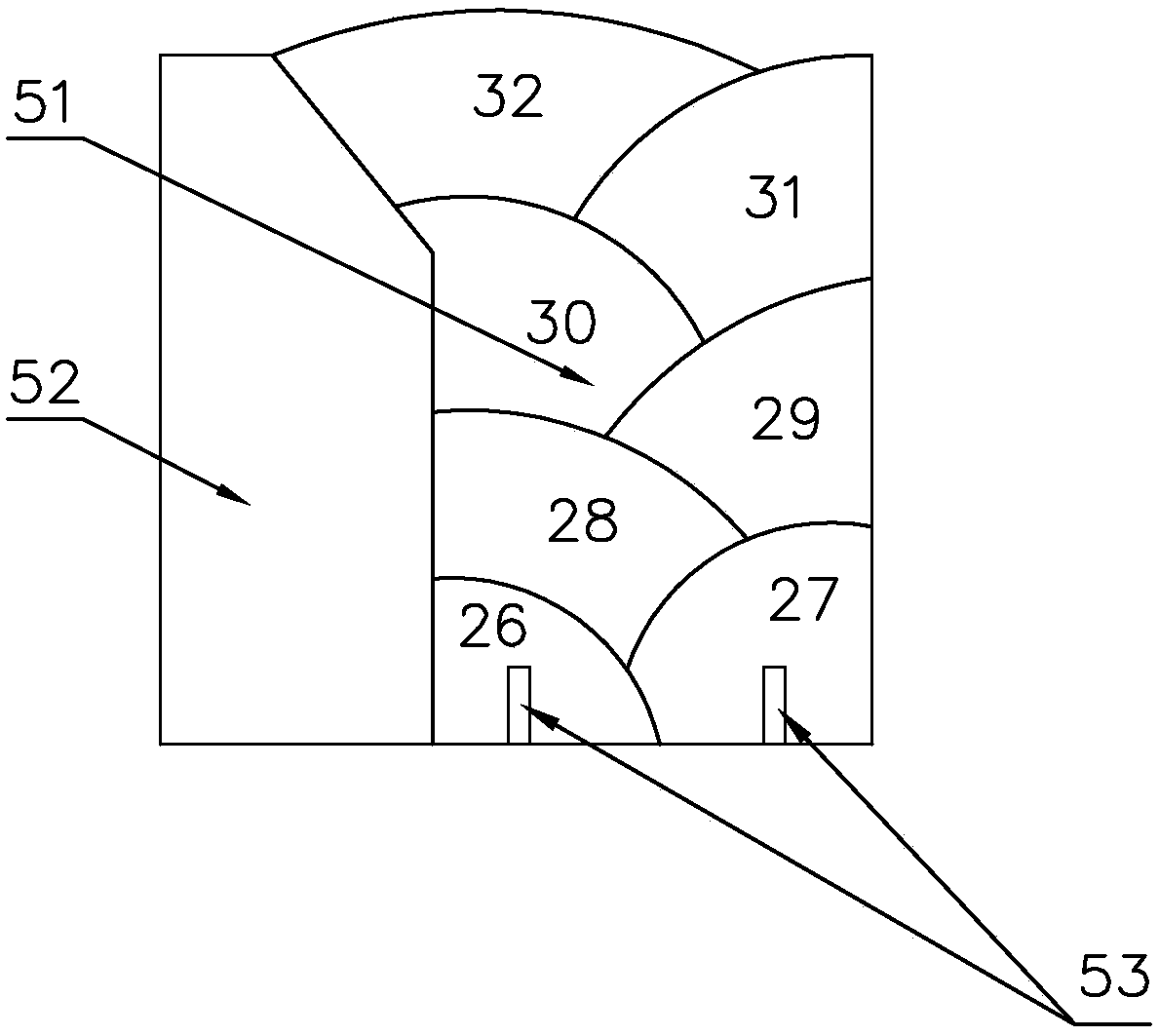

Embodiment 3

[0094] The difference from Example 1 is: the thickness of the base plate is 170mm, the thickness of the cladding plate is 30mm, the total reduction rate is 77.5%, the specification of the composite plate after rolling is 44000mm×1250mm×45mm, and the composite plate after forming is sheared The strength is 525MPa;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com