Steel powder core wire material for arc cladding additive manufacturing and preparation method thereof

A technology of additive manufacturing and cladding, applied in the field of steel powder core wire materials for arc cladding additive manufacturing, which can solve the problems of discontinuous production process, difficult filling, low efficiency, etc., and achieve uniform powder distribution and stability Good and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

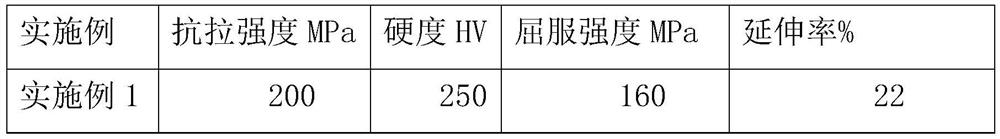

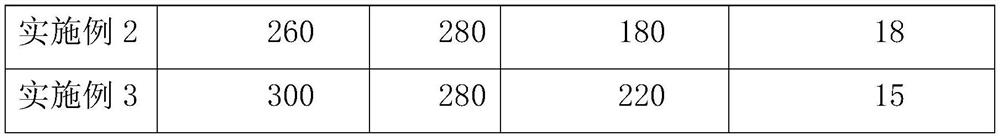

Examples

Embodiment 1

[0036] Step 1, cutting the 1mm low carbon steel strip and 15 steel plate into steel strips of different widths for subsequent use;

[0037] Step 2. Powder core preparation: select alloy powders with different components according to different needs, add copper powder as a binder for alloy materials, add different carbon powders to adjust the composition of steel, and evenly mix powder materials with different ratios to obtain a mixture . For example, Fe powder, Ni powder, Cu powder, Co powder, and Cr powder are mixed in equal mole fractions and put into a high-energy ball mill at a speed of 150r / min for 2 hours to obtain alloy powder with uniform composition;

[0038] Step 3, spreading the alloy powder evenly on the matrix steel strip;

[0039] Step 4, pre-sintering the steel strip covered with alloy powder through a crawler sintering furnace;

[0040] Step 5, rolling the pre-sintered strip;

[0041] Step 6, rolling the sintered steel strip into a circle through a plate rol...

Embodiment 2

[0045] Step 1, cutting the 1mm low carbon steel strip 20 steel plate into steel strips of different widths for subsequent use;

[0046] Step 2. Powder core preparation: select alloy powders with different components according to different needs, add copper powder as a binder for alloy materials, add different carbon powders to adjust the composition of steel, and evenly mix powder materials with different ratios to obtain a mixture . For example, Fe powder, Ni powder, Cu powder, Co powder, and Cr powder are mixed in equal mole fractions and put into a high-energy ball mill at a speed of 150r / min for 2 hours to obtain alloy powder with uniform composition;

[0047] Step 3, spreading the alloy powder evenly on the matrix steel strip;

[0048] Step 4, pre-sintering the steel strip covered with alloy powder through a crawler sintering furnace;

[0049] Step 5, rolling the pre-sintered strip;

[0050] Step 6, rolling the sintered steel strip into a circle through a plate rolling...

Embodiment 3

[0054] Step 1. Cut the 1mm medium carbon steel strip 30 steel plate into steel strips of different widths for later use;

[0055] Step 2. Powder core preparation: select alloy powders with different components according to different needs, add copper powder as a binder for alloy materials, add different carbon powders to adjust the composition of steel, and evenly mix powder materials with different ratios to obtain a mixture . For example, Fe powder, Ni powder, Cu powder, Co powder, and Cr powder are mixed in equal mole fractions and put into a high-energy ball mill at a speed of 150r / min for 2 hours to obtain alloy powder with uniform composition;

[0056] Step 3, spreading the alloy powder evenly on the matrix steel strip;

[0057]Step 4, pre-sintering the steel strip covered with alloy powder through a crawler sintering furnace;

[0058] Step 5, rolling the pre-sintered strip;

[0059] Step 6, rolling the sintered steel strip into a circle through a plate rolling machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com