Mold filling differential pressure determining method based on vacuum differential pressure casting classified pressurizing mold filling

A technology of differential pressure casting and method determination, which is applied in design optimization/simulation, special data processing applications, complex mathematical operations, etc. It can solve problems such as no relevant reports, errors, and pressure changes affecting gas volume, etc., to improve control accuracy , reduce oxidation slag, achieve the effect of stability and sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

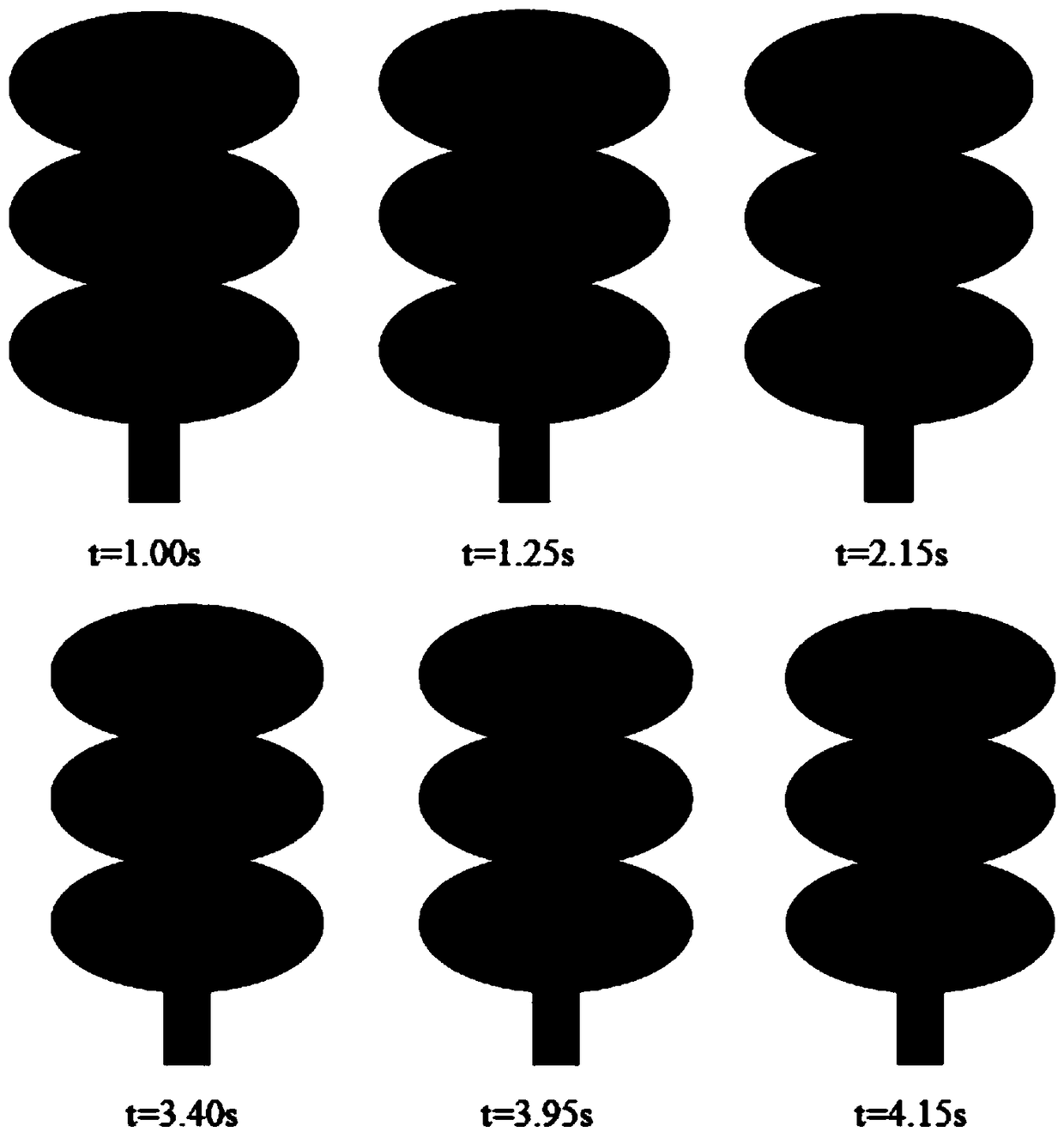

[0032] Figure 4 It is a three-dimensional view of an aluminum alloy casting. The thicknesses of the three thin-walled planes from bottom to top are 3mm, 4mm, and 5mm respectively, and the diameter is 300mm. The distance between the thin-walled planes is 160mm.

[0033] In the vacuum differential pressure casting process, the pressure inside the casting tank is 0.01MPa, and at the liquid metal filling section I, p 1 = 0.01MPa, according to the Reynolds formula, the maximum filling pressure difference required to ensure the laminar flow in the riser is 0.015MPa, so the initial pressure p acting on the liquid surface 2 =0.025MPa, according to the relationship between the filling pressure difference and the filling speed established by the principle of conservation of momentum, the filling speed v can be calculated 1 =0.164m / s, by the attached image 3 The Bernoulli equation is established between the step-by-step pressurized filling sections shown, and the relationship between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com