Corrosion prevention production line for epoxy layer of outer surface of welding steel tube and corrosion prevention technology

A technology for welding steel pipes and outer surfaces, applied in the direction of pretreatment of the surface, device for coating liquid on the surface, coating, etc., to achieve a uniform effect on the surface of the layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments.

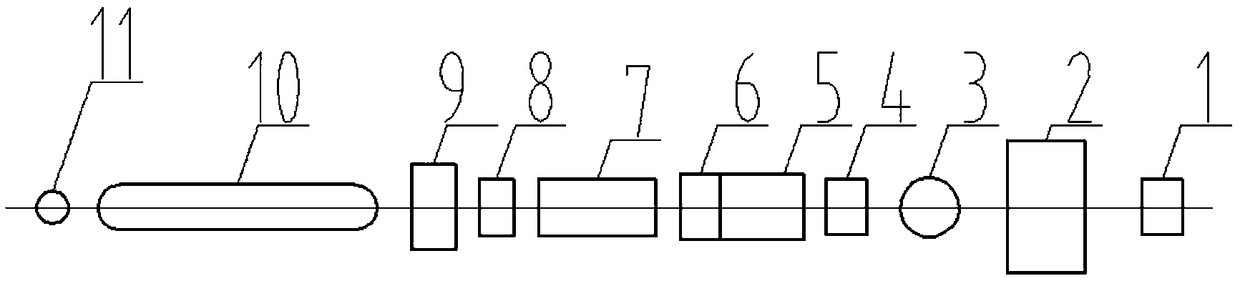

[0027] like figure 1 The anti-corrosion production line for the epoxy layer on the outer surface of welded steel pipes shown is composed of an intermediate frequency preheating furnace 1, an outer wall rust remover 2, a dust treatment and dust removal device 3, a flame preheating furnace 4, and a phosphating reaction chamber 5. , Clean water cleaning room 6, air drying room 7, intermediate frequency heating furnace 8, epoxy spraying device 9, coating water cooling device 10, spark leak detection device 11. The production line is used to carry out the anti-corrosion process of the epoxy layer on the outer surface of the welded steel pipe. The specific steps are:

[0028] (1) Preheating: the welded steel pipe is preheated through the intermediate frequency preheating furnace 1, and the grease on the surface of the steel pipe is burned at the same time;

[0029] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com