A kind of preparation method of polyurethane-based composite photocatalytic film

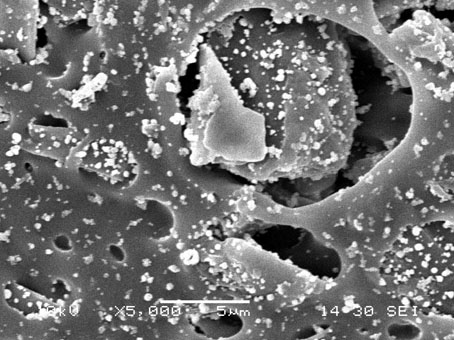

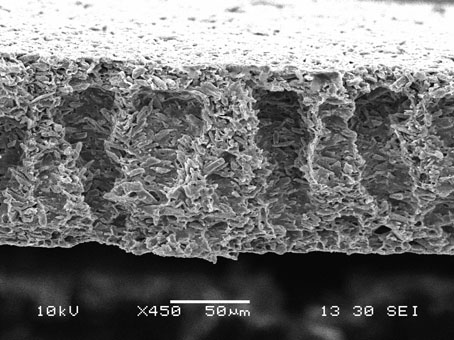

A composite photocatalysis and polyurethane technology, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problems of poor mechanical properties, difficult recycling, and limited Application and other issues, to achieve the effect of easy recycling, uniform particle size and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

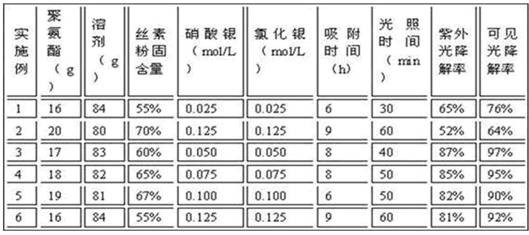

Embodiment 1

[0042] One of the embodiments of the preparation method of a polyurethane-based composite photocatalytic membrane of the present invention comprises the following steps:

[0043] Step 1. Preparation of polyurethane solution: Weigh 16 grams of polyester thermoplastic polyurethane particles with a Shore hardness of 55A, disperse them in 84 grams of N,N-dimethylformamide solvent, stir well at room temperature, and obtain a mass fraction of 16 % polyurethane polymer solution;

[0044] Step 2, preparing the coating solution: adding silk fibroin powder with a specification of 10 μm and a solid content of 55% to the above-mentioned polyurethane polymer solution with a mass fraction of 16%, and stirring evenly to obtain a coating solution;

[0045] Step 3. Prepare the polyurethane / silk fibroin blend film: let the coating solution stand for 30 minutes, evenly coat it on the release paper after defoaming, and control the film by adjusting the thickness of the coating solution coated on ...

Embodiment 2

[0051] One of the embodiments of the preparation method of a polyurethane-based composite photocatalytic membrane of the present invention comprises the following steps:

[0052] Step 1: Preparation of polyurethane solution: Weigh 20 grams of polyester thermoplastic polyurethane particles with a Shore hardness of 65A, disperse them in 80 grams of N,N-dimethylformamide solvent, stir well at room temperature, and obtain a mass fraction of 20 % polyurethane polymer solution;

[0053] Step 2: Prepare a coating solution: add silk fibroin powder with a specification of 10 μm and a solid content of 70% to the polyurethane polymer solution with a mass fraction of 20% above, and stir evenly to obtain a coating solution;

[0054] Step 3: Prepare the polyurethane / silk fibroin blend film: let the coating solution stand for 30 minutes, quickly and evenly coat it on the release paper after defoaming, and control the thickness of the coating solution coated on the release paper by adjusting ...

Embodiment 3

[0060] One of the embodiments of the preparation method of a polyurethane-based composite photocatalytic membrane of the present invention comprises the following steps:

[0061] Step 1: Preparation of polyurethane solution: Weigh 17 grams of polyester thermoplastic polyurethane particles with a Shore hardness of 60A, disperse them in 83 grams of N,N-dimethylformamide solvent, stir well at room temperature, and obtain a mass fraction of 17 % polyurethane polymer solution;

[0062] Step 2: Prepare coating solution: add silk fibroin powder with a specification of 8 μm and a solid content of 60% to the polyurethane polymer solution with a mass fraction of 17% above, and stir evenly with a magnetic stirrer to obtain a coating solution;

[0063] Step 3: Prepare the polyurethane / silk fibroin blend film: let the coating solution stand for 30 minutes, quickly and evenly coat it on the release paper after defoaming, and control the thickness of the coating solution coated on the releas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com