Preparation method of granular drinking water arsenic-removing adsorption material

An adsorption material and granular technology, which is applied in the field of preparation of arsenic removal adsorption materials for drinking water, can solve the problems of poor mechanical properties of powder materials, difficult solid-liquid separation, and difficult simultaneous removal, etc., and achieves high mechanical strength, low cost, and easy The effect of solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

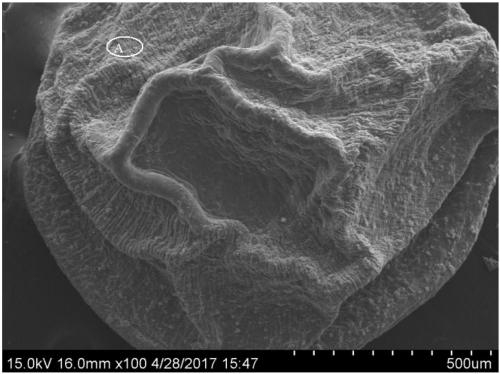

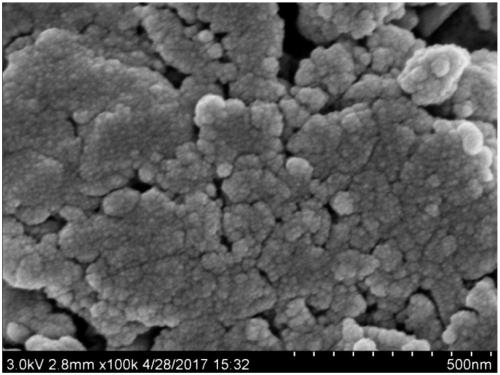

Image

Examples

specific Embodiment approach 1

[0026] Specific Embodiment 1: This embodiment is a preparation method of a granular drinking water arsenic removal adsorption material, which is specifically carried out according to the following steps:

[0027] 1. Mix soluble iron salt and soluble titanium salt in water to prepare solution a;

[0028] 2. Mix soluble permanganate and basic compound I in water to prepare solution b;

[0029] 3. Under the condition of rapid stirring, drop solution b into solution a drop by drop, and then continue to stir for 10min~2h to obtain solution c with a pH of 6~9; stand and age for 1h~4h, pour out the supernatant , wash the solid precipitate repeatedly with deionized water until no anions are detected by ion chromatography; filter the precipitate with suction to obtain a filter cake, dry it at 20°C to 120°C, grind it, pass through a sieve of 80 mesh to 100 mesh, Obtain powdery arsenic removal adsorption material;

[0030] 4. Under the condition of stirring, dissolve chitosan in weak a...

specific Embodiment approach 2

[0041] Embodiment 2: This embodiment differs from Embodiment 1 in that the soluble ferrous salt is one or a mixture of ferrous chloride and ferrous sulfate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0042] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the soluble ferric salt is one or a mixture of ferric chloride, ferric sulfate and ferric nitrate. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com