Antibacterial dressing for hepatobiliary surgery

A surgical and hepatobiliary technology, applied in medical science, bandages, absorbent pads, etc., can solve the problems of hydrogel dressings with no antibacterial and bacteriostatic effect, no antibacterial and bacteriostatic ingredients, and poor wound wettability, etc., and achieves strong hygroscopic effect. , enhance effect, enhance antibacterial and anti-inflammatory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

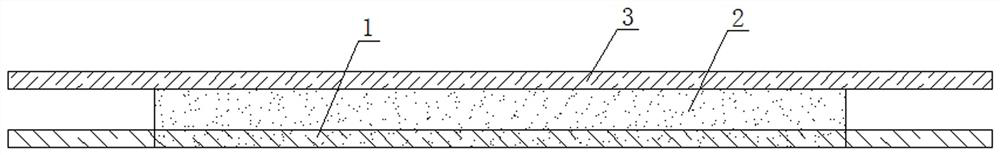

[0030] An antibacterial dressing for hepatobiliary surgery, such as figure 1 As shown, it includes fiber layer one 1, gel layer 2 and fiber layer two 3 arranged sequentially from the inside and outside, wherein the gel layer 2 is made of the following raw materials in parts by weight: 45 parts of acrylic acid, N-methylol 40 parts of acrylamide, 20 parts of polyvinyl alcohol, 1 part of aluminum glycylate, 8 parts of talcum powder, 1 part of polypropylene fiber, 4 parts of sodium carboxymethyl cellulose, 12 parts of polyvinylpyrrolidone, N, N-methylene 0.6 parts of bisacrylamide, 0.5 parts of sodium persulfate and 200 parts of water.

[0031] Wherein fiber layer one 1 is 2 layers of grid gauze, and described fiber layer two 3 is bamboo charcoal fiber non-woven fabric.

[0032] Wherein the gel in the gel layer is prepared by the following steps:

[0033] (1) Dissolve acrylic acid in water, add polyvinyl alcohol, N-methylolacrylamide, and polyvinylpyrrolidone in turn and stir we...

Embodiment 2

[0040] An antibacterial dressing for hepatobiliary surgery, such as figure 1 As shown, it includes fiber layer one 1, gel layer 2 and fiber layer two 3 arranged sequentially from the inside and outside, wherein the gel layer 2 is made of the following raw materials in parts by weight: 46 parts of acrylic acid, N-methylol 42 parts of acrylamide, 18 parts of polyvinyl alcohol, 1.2 parts of aluminum glycylate, 7 parts of talcum powder, 1.2 parts of polypropylene fiber, 5 parts of sodium carboxymethyl cellulose, 11 parts of polyvinylpyrrolidone, N, N-methylene 0.7 parts of bisacrylamide, 0.6 parts of sodium persulfate and 220 parts of water.

[0041] Wherein fiber layer one 1 is 2 layers of grid gauze, and described fiber layer two 3 is bamboo charcoal fiber non-woven fabric.

[0042] Wherein the gel in the gel layer is prepared by the following steps:

[0043] (1) Dissolve acrylic acid in water, add polyvinyl alcohol, N-methylolacrylamide, and polyvinylpyrrolidone in turn and sti...

Embodiment 3

[0050] An antibacterial dressing for hepatobiliary surgery, such as figure 1 As shown, it includes fiber layer one 1, gel layer 2 and fiber layer two 3 arranged sequentially from the inside and outside, wherein the gel layer 2 is made of the following raw materials in parts by weight: 48 parts by weight of acrylic acid, N-methylol 44 parts of acrylamide, 16 parts of polyvinyl alcohol, 1.4 parts of aluminum glycylate, 6 parts of talcum powder, 1.4 parts of polypropylene fiber, 6 parts of sodium carboxymethyl cellulose, 10 parts of polyvinylpyrrolidone, N, N-methylene 0.8 parts of bisacrylamide, 0.7 parts of sodium persulfate and 250 parts of water.

[0051] Wherein fiber layer one 1 is 2 layers of grid gauze, and described fiber layer two 3 is bamboo charcoal fiber non-woven fabric.

[0052] Wherein the gel in the gel layer is prepared by the following steps:

[0053] (1) Dissolve acrylic acid in water, add polyvinyl alcohol, N-methylolacrylamide, and polyvinylpyrrolidone in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com