Precise depth-controlled groove milling-based manufacture method of microwave printed circuit board

A technology of printed circuit boards and manufacturing methods, which is applied in the direction of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of low production efficiency, inability to do it accurately, and inability to control the tolerance of PCB boards well, so as to ensure zero Residue, the effect of ensuring signal integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] This embodiment provides a method for manufacturing a circuit board, including a method for manufacturing a microwave printed circuit board with precisely controlled depth milling grooves. The specific process is as follows:

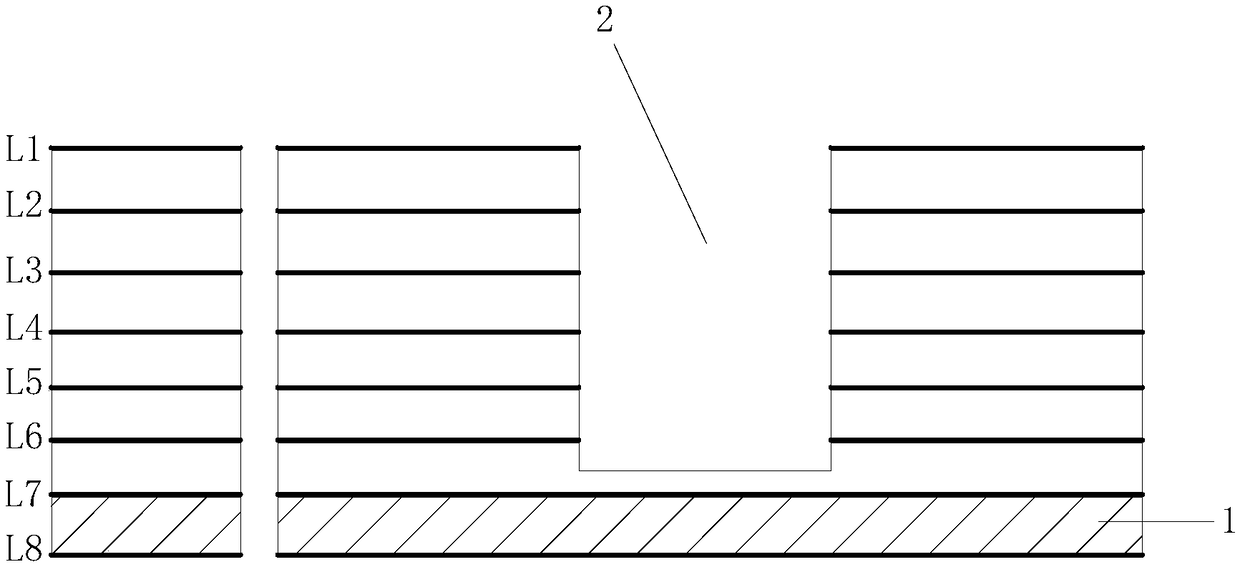

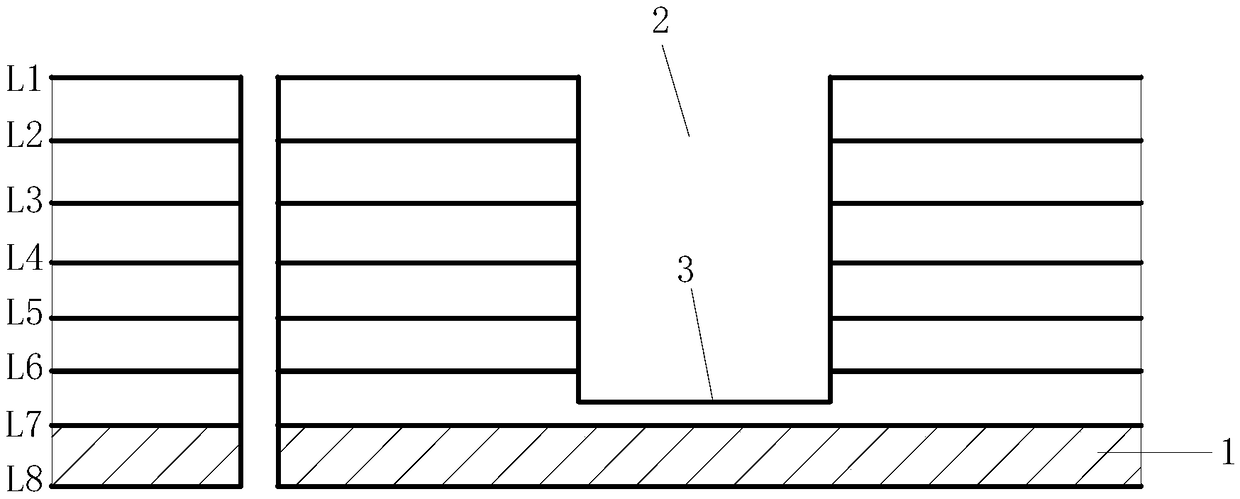

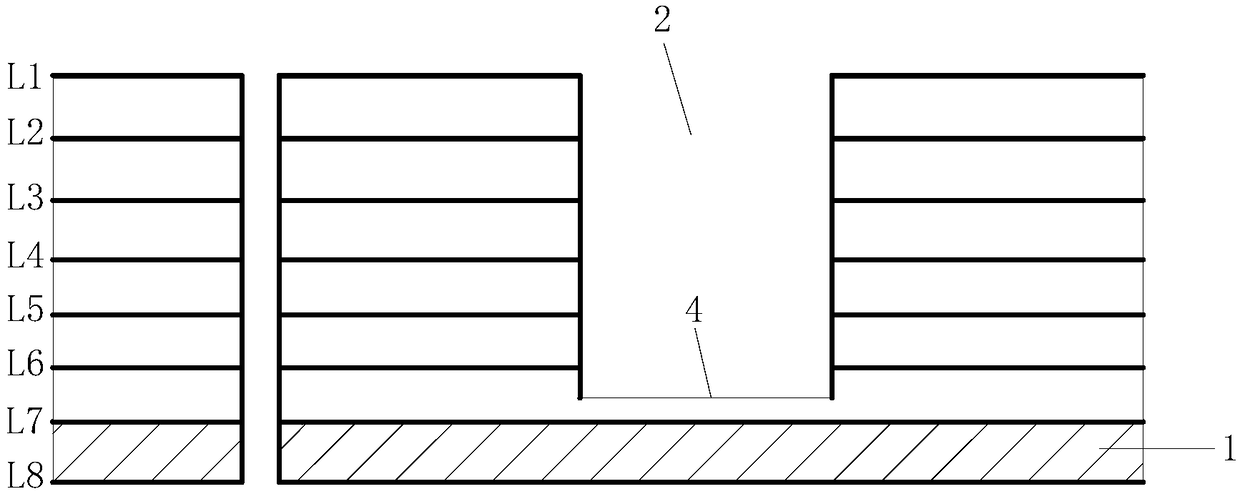

[0030] (1) Cutting: Cut out four core boards according to the board size 520mm×620mm, such as figure 1 As shown, the four core boards are the L1-L2 layer, L3-L4 layer, L5-L6 layer, and L7-L8 layer in the figure, and the dielectric layer of the L7-L8 layer core board is Rogers high-frequency board.

[0031] (2), inner layer circuit making (negative film process): inner layer graphics transfer, coating photosensitive film on the core board with a vertical coating machine, the film thickness of the photosensitive film is controlled at 8 μm, and a fully automatic exposure machine is used to 5-6 Grid exposure ruler (21 grid exposure ruler) completes the exposure of the inner layer circuit on the core board; inner layer etching, etches the inner layer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com