A kind of nutmeg gap positioning cutting triple recognition non-destructive full separation picking vehicle

A technology of positioning cutting and positioning recognition, which is applied in the direction of picking machines, solid separation, and separation of solids from solids with airflow, which can solve problems such as low separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of this patent will be described in further detail below in conjunction with the specific implementation. The technical features or connection relationships described in the present invention are not described in detail. They are all existing technologies adopted. The present invention will be described in further detail below in conjunction with the accompanying drawings.

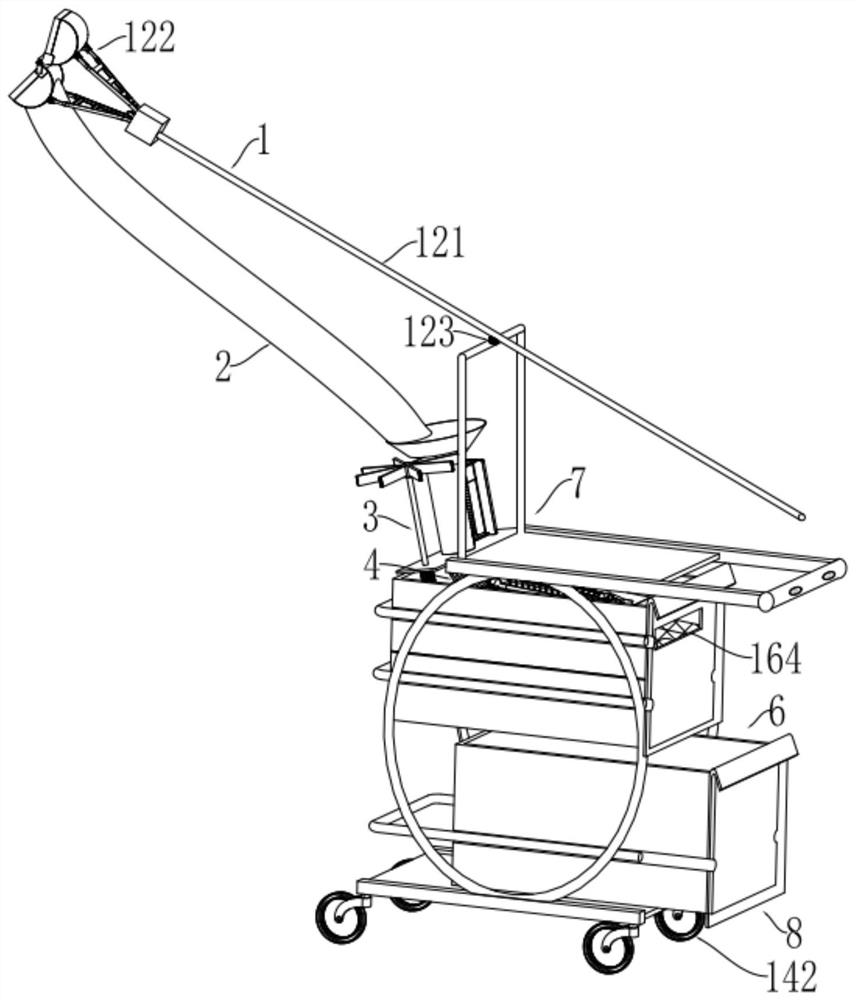

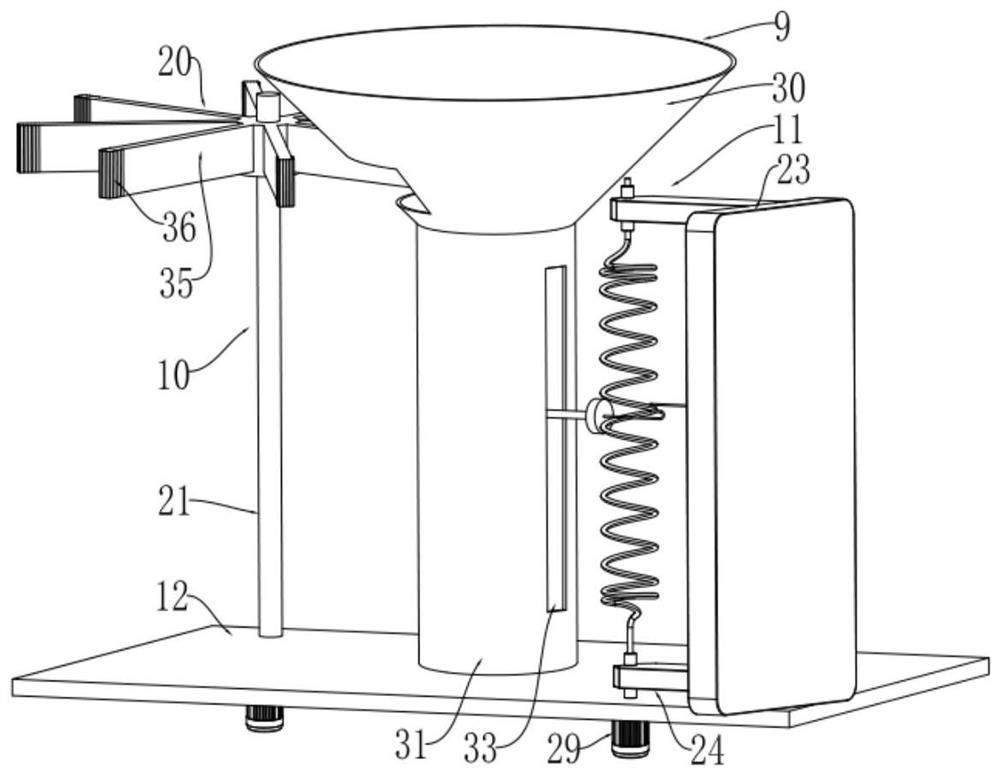

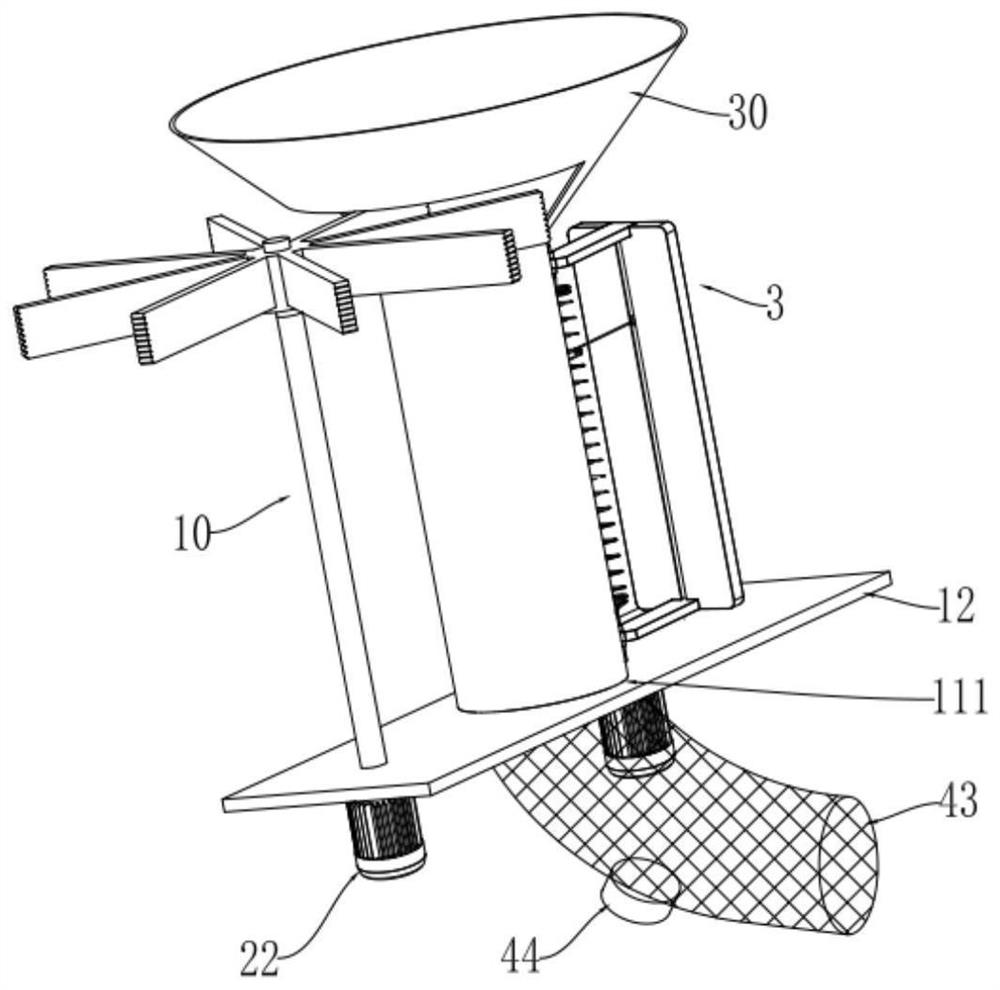

[0034] Such as Figure 1-16As shown, a nutmeg gap positioning cutting triple recognition non-destructive full-separation picking vehicle includes a non-destructive wrapping picking mechanism 1 for branches, leaves and fruits, a non-destructive flexible downpipe 2, and a self-rotating push-down type precise positioning double-recognition gap full-cutting mechanism 3 , Oblique downward planing, digging, pulp and core recognition positioning friction full separation mechanism 4, 360° cross-rotating scraping type aril full peeling mechanism 5, screening loading mechanism 6, suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com