Temperature control device and method for battery pack

A technology of temperature control device and temperature control method, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of large impact force of cold plate, poor battery temperature uniformity, and uncontrollable temperature difference between inlet and outlet water, so as to prevent the use of Lifespan, the effect of improving the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

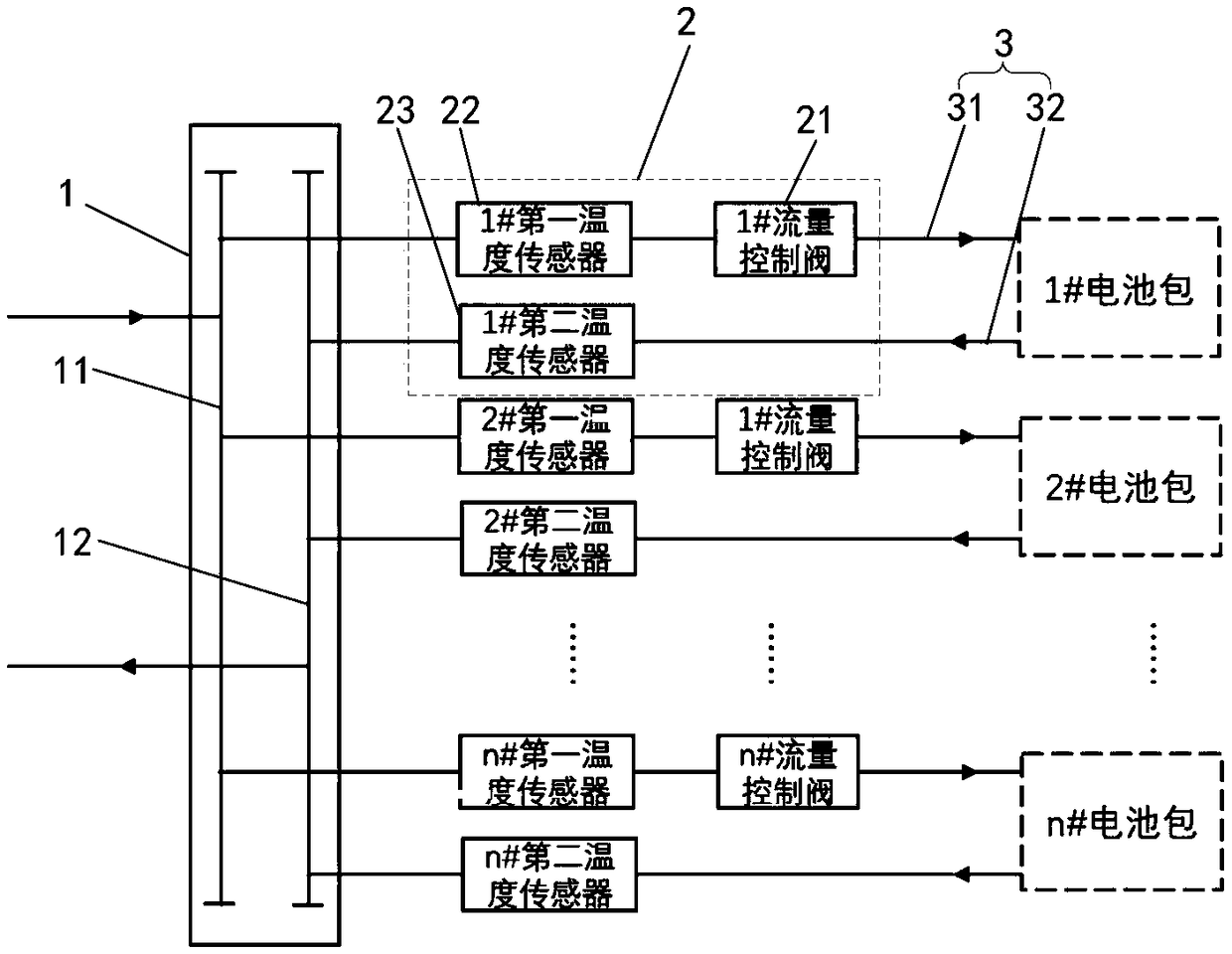

[0072] The flow control parameter set by the user above can be the set flow rate (that is, the flow rate of the coolant suitable for the battery pack set according to the model of the battery pack connected to the pipeline 3), and then through the flow control module 2 The parameter acquisition unit acquires the set flow rate, so that the flow control unit 21 in the flow control module 2 can control the flow rate of the cooling fluid flowing through the battery pack according to the set flow rate.

[0073] In a specific embodiment, such as figure 1 As shown, the user sets the flow rate for the 1# battery pack. Specifically, the user can select the flow rate corresponding to the 1# battery pack in the specified flow range through the software operation interface. After the user selection is completed, and the parameter acquisition unit obtains After reaching the flow rate selected by the user, the flow control unit 21 automatically adjusts to fix the flow rate of the cooling li...

Embodiment 2

[0075] The above-mentioned flow control parameters set by the user through the control panel can be the preset temperature range (that is, the difference range between the temperature of the coolant in the water supply pipeline 31 and the temperature of the coolant in the return water pipeline 32 set according to the model of the battery pack ), specifically, first, the flow control unit 21 controls the flow of the coolant flowing through the battery pack according to the initial flow, (the initial flow is obtained based on the empirical value of the temperature difference flow relationship), and then through the water supply provided in each pipeline 3 The first temperature sensor 22 in the pipeline 31 detects the first current temperature of the coolant in the water supply pipeline 31, and the second temperature sensor 23 in the return water pipeline 32 arranged in each pipeline 3 detects the return pipe The second current temperature of the coolant in the road 32, and then c...

Embodiment 3

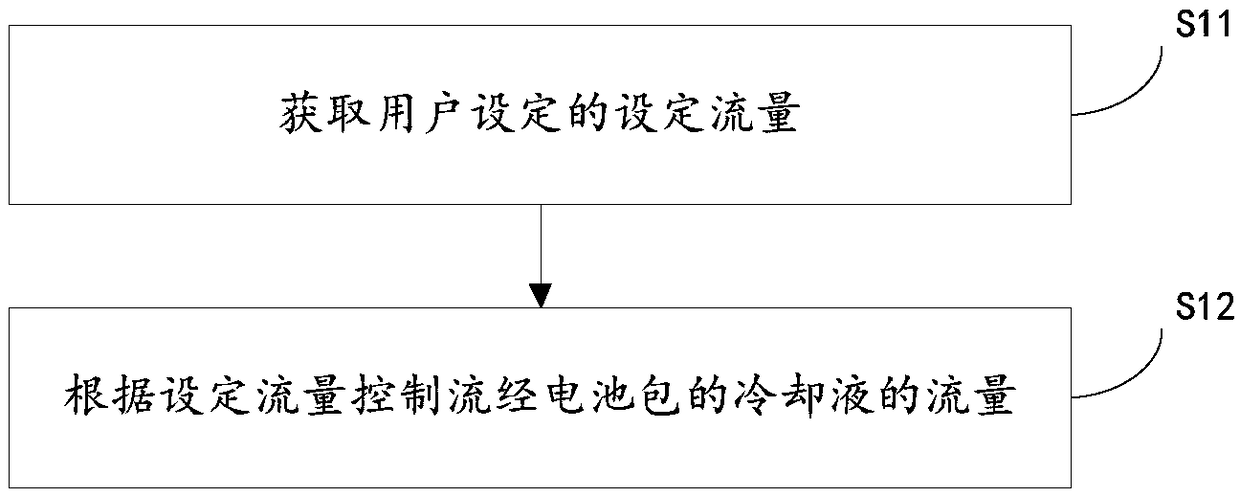

[0090] When the flow control parameter set by the above user is the set flow, the method specifically includes the following steps:

[0091] Step S11 , acquiring the set flow rate set by the user.

[0092] Specifically, the set flow rate is the flow rate of the coolant suitable for the battery pack set according to the model of the battery pack connected to the corresponding pipeline. The user can set the set flow rate through the software operation interface, and then obtain the set flow rate set by the user through the parameter acquisition unit in the flow control module.

[0093] Step S12, controlling the flow rate of the cooling liquid flowing through the battery pack according to the set flow rate.

[0094] Specifically, the flow control unit in the flow control module controls the flow of the coolant flowing through the battery pack according to the set flow obtained by the parameter acquisition unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com