Formation method for semiconductor devices

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve problems such as inability to form patterns accurately, and achieve the effects of not easy etching loss, improved mechanical properties, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

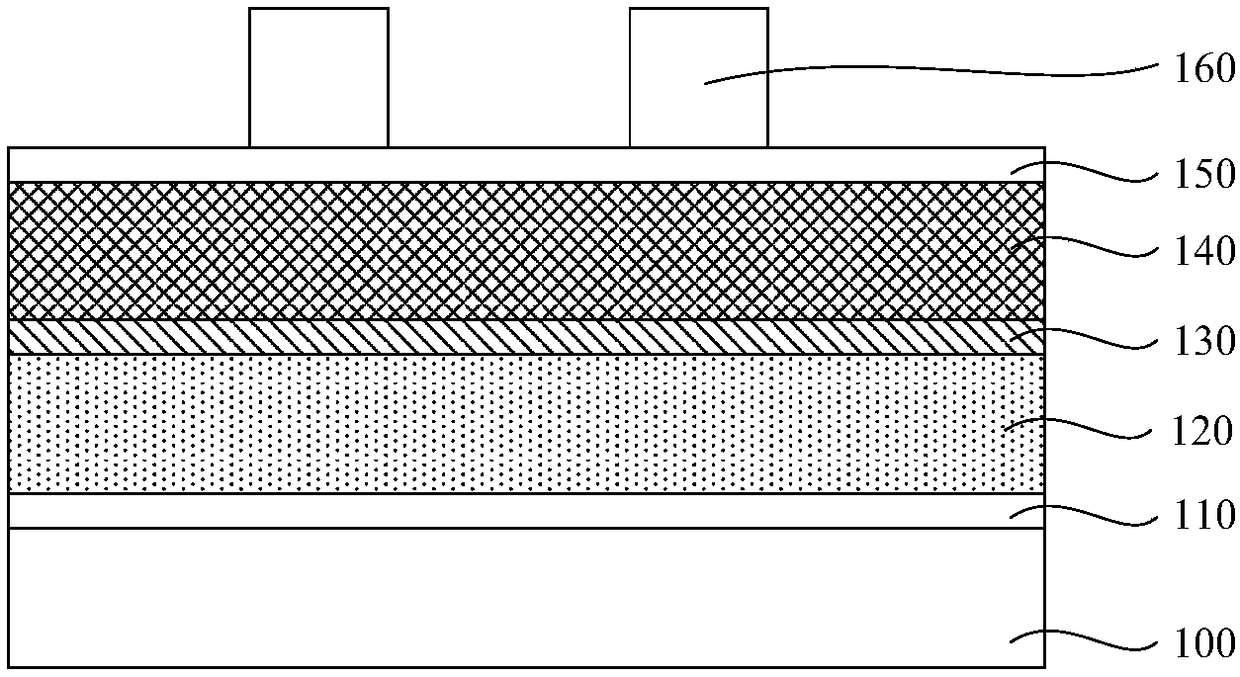

[0035] As mentioned above, the mask layer material used in the existing ASQP process has relatively large loss during the etching process, and the size, structure, and shape of the mask layer have changed greatly, and subsequent patterns cannot be accurately formed.

[0036] Research has found that the reasons for the above problems are: the mechanical properties of the mask layer material used are relatively low in hardness and strength, the material to be etched has relatively small etching options relative to the mask layer, and the mask layer has a relatively low resistance to etching. Weak, easy to be worn out during further etching.

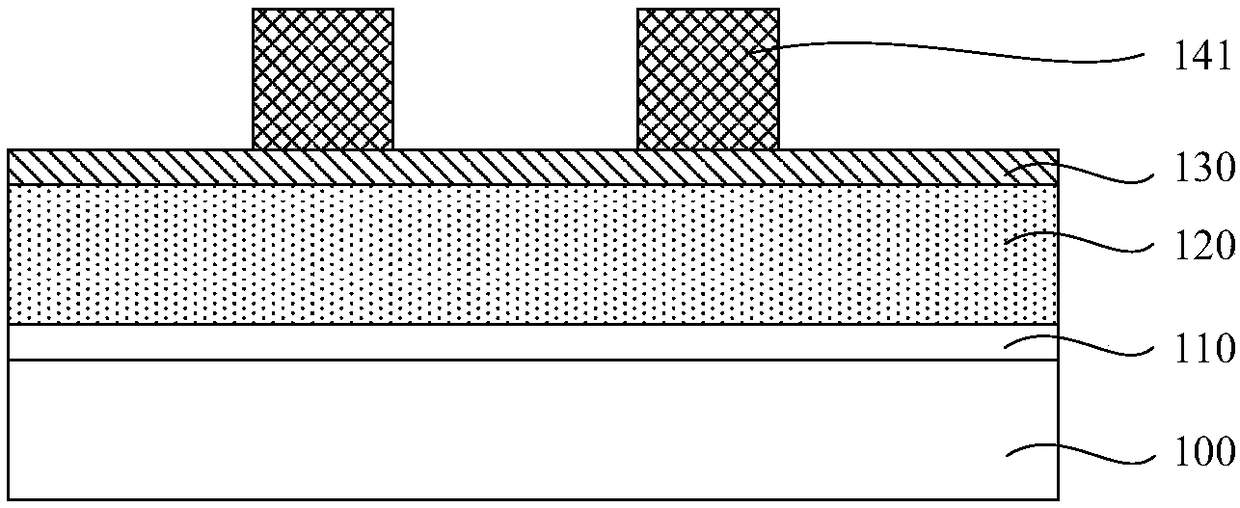

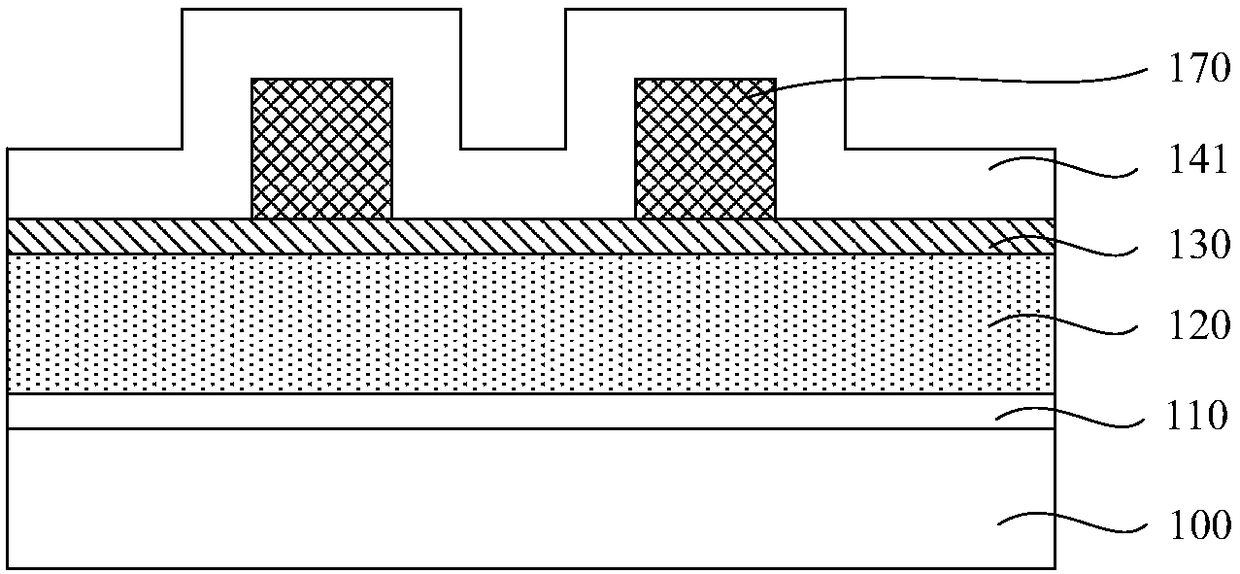

[0037] In order to solve this problem, the present invention provides a mechanical property such as strength and hardness relative to TiO x Higher material ZrO x As a mask layer material. Under the same etching process conditions, the rate at which the mask layer is etched is much lower than the rate at which the material to be etched is etched....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com