A Miniature Free Piston Generator with Compound Combustion Chamber Structure

A combustion chamber and generator technology, applied in the field of micro-power systems, can solve the problems that the integration and modularization of micro-free piston generators cannot be realized, the utilization of waste heat of exhaust gas is not considered, and the space occupancy rate is high. The ignition timing is advanced and the space occupation rate is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

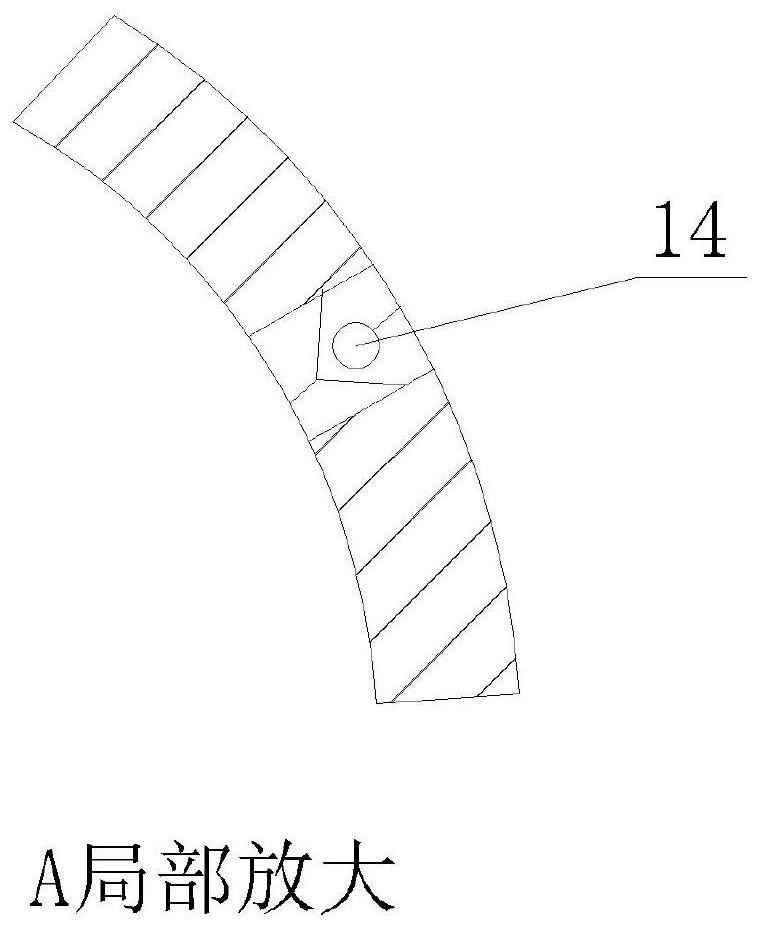

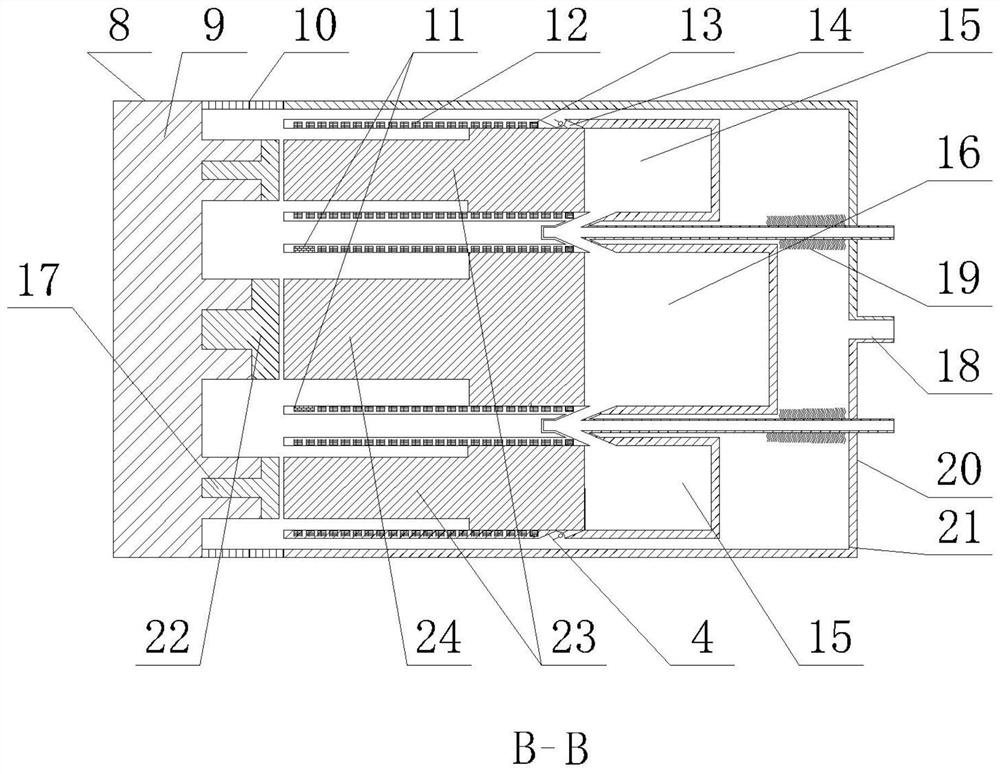

[0037] Such as Figure 1-Figure 3 As shown, the miniature free piston generator with a compound combustion chamber structure according to the present invention includes a first miniature free piston power device 7, a second miniature free piston power device 5, and a body 1. The body 1 is provided with a first A miniature free piston power unit 7 and a second miniature free piston power unit 5. The first miniature free piston power unit 7 is provided with a first combustion chamber 16, and the first combustion chamber 16 is provided with an air inlet and a second The air outlet 6 of a miniature free piston power unit, the second miniature free piston power unit 5 is provided with a second combustion chamber 15, and the second combustion chamber 15 is provided with an air inlet and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com