Preparation method of shell powder interior wall coating with remarkable humidity-control performance

A technology of interior wall paint and shell powder, applied in the direction of coating, can solve the problems of poor scrub resistance and low humidity control ability, and achieve the effects of strong adsorption capacity, enhanced affinity and enhanced compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

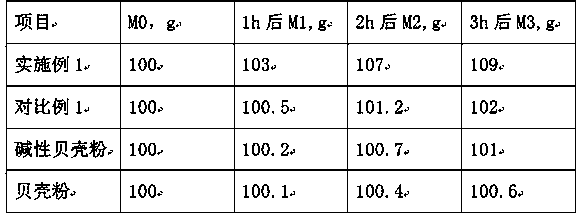

Examples

Embodiment 1

[0024] A preparation method of shell powder interior wall paint with remarkable humidity control performance, comprising the following steps:

[0025] S1: Preparation of modified shell powder

[0026] (1) Put the shells collected in the market into the cleaning solution, after soaking, wash the surface with clean water, dry and crush to obtain shell powder, then add the shell powder to ammonia water three times its weight In the process, after soaking for 50 minutes, centrifuge to obtain a precipitate, and dry the precipitate to obtain alkaline shell powder;

[0027] (2) In parts by weight, add 40 parts of N-isopropylacrylamide to 120 parts of water, stir under nitrogen protection until fully dissolved, and then add 10 parts of stearyl methacrylate with sodium hydroxide solution Adjust its pH to 7.0, slowly add it to N-isopropylacrylamide, then add 0.1 part of potassium persulfate to it, react for 18 hours, and rinse the reaction product repeatedly to obtain a hydrogel, and a...

Embodiment 2

[0037] A preparation method of shell powder interior wall paint with remarkable humidity control performance, comprising the following steps:

[0038] S1: Preparation of modified shell powder

[0039] (1) Put the shells collected in the market into the cleaning solution, after soaking, wash the surface with clean water, dry and pulverize to obtain shell powder, and then add the shell powder to ammonia water 4 times its weight In the process, after soaking for 55 minutes, centrifuge to obtain a precipitate, and dry the precipitate to obtain alkaline shell powder;

[0040] (2) In parts by weight, add 45 parts of N-isopropylacrylamide to 130 parts of water, stir under nitrogen protection until fully dissolved, and then add 13 parts of stearyl methacrylate with sodium hydroxide solution Adjust its pH to 7.0, slowly add it to N-isopropylacrylamide, then add 0.2 parts of potassium persulfate to it, react for 19 hours, and rinse the reaction product repeatedly to obtain a hydrogel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com