High-toughness and weather-resistant plastic photovoltaic scaffold

A photovoltaic bracket and weather-resistant technology, applied in the field of high-toughness and weather-resistant plastic photovoltaic brackets, can solve the problems of inconvenient handling and installation, low bearing capacity, easy corrosion, etc., and achieve the effect of excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

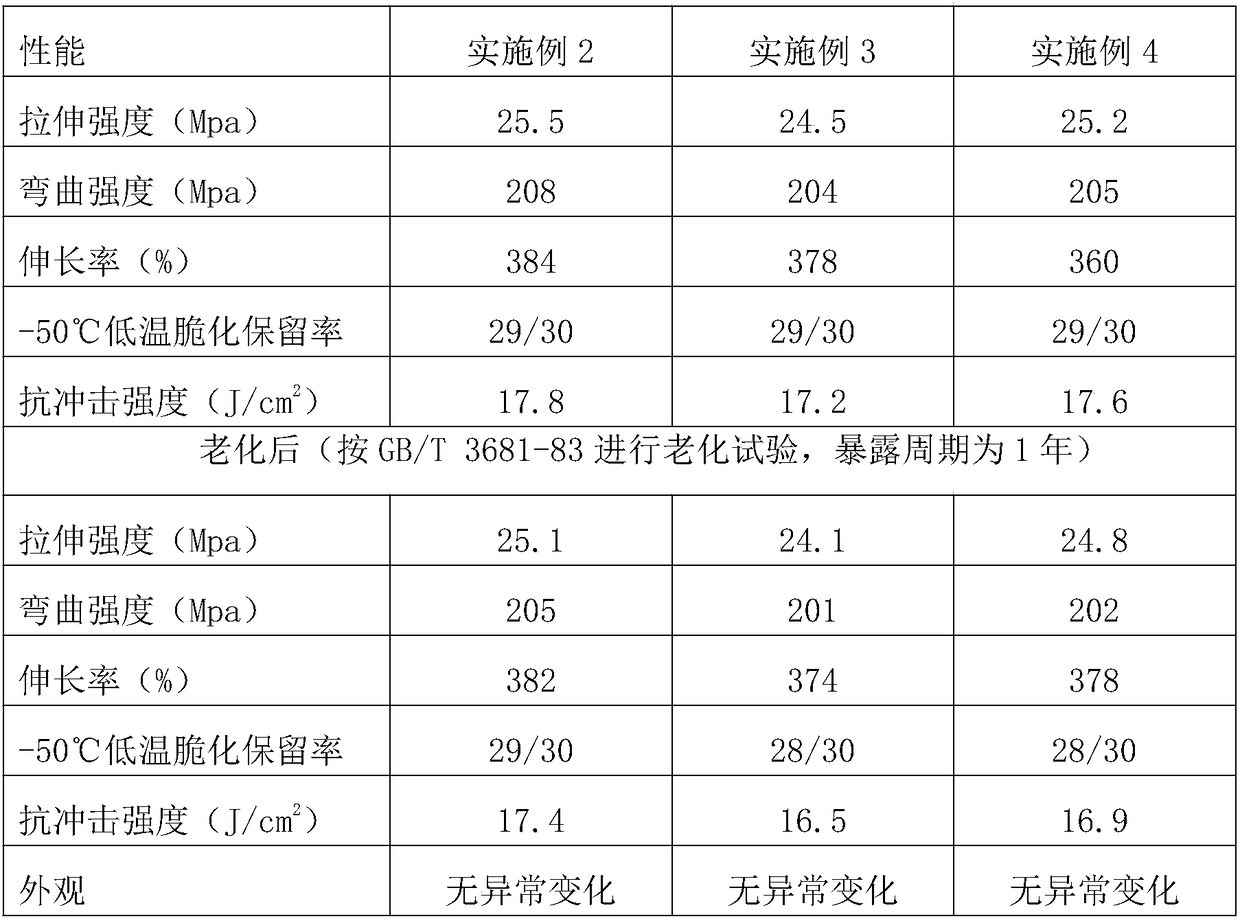

Examples

Embodiment 1 2

[0021] The preparation of embodiment 1 titanium dioxide-attapulgite composite

[0022] 1) Disperse attapulgite with a mesh number of 800-1000 into 38 wt% hydrochloric acid solution under ultrasonic conditions, reflux in a water bath at 100°C for 16 hours, filter, wash until neutral and dry to obtain purified attapulgite for later use;

[0023] 2) Stir 100 g of the purified attapulgite evenly, then add 1 L of tetrabutyl titanate, 12 L of ethanol, 10 L of acetylacetone, and 12 L of deionized water, stir and react at room temperature to obtain a sol and then turn it into a gel. The obtained gel is dried, calcined and ground to obtain titanium dioxide modified attapulgite.

[0024] 3) Add 10 g of silicone oil to the obtained titanium dioxide-attapulgite composite by spraying, stir evenly, then add 5 g of silane coupling agent under high-speed stirring at 1500-2000 r / min, and mix evenly.

Embodiment 2

[0025] Example 2 A kind of high-toughness and weather-resistant plastic photovoltaic support

[0026] It consists of the following raw materials in parts by weight: 100 parts of polyvinyl chloride, 2.5 parts of calcium zinc stabilizer, 10 parts of CPE, 3 parts of nitrile rubber, 0.5 part of paraffin wax, 0.4 part of PE wax, 0.4 part of ACR-P551, calcium sulfate whisker 10 parts, 5 parts of titanium dioxide, 10100.5 parts of antioxidant, 0.2 part of UV531, 2 parts of rare earth stabilizer, 15 parts of titanium dioxide-attapulgite composite prepared in Example 1.

Embodiment 3

[0027] Example 3 A kind of high toughness and weather-resistant plastic photovoltaic support

[0028] It consists of the following raw materials in parts by weight: 110 parts of polyvinyl chloride, 3 parts of calcium zinc stabilizer, 12 parts of CPE, 4 parts of nitrile rubber, 0.8 part of paraffin wax, 0.6 part of PE wax, 0.4 part of ACR-P551, calcium sulfate whisker 12 parts, 5 parts of titanium dioxide, 0.5 parts of antioxidant 1010, 0.2 parts of UV531, 2 parts of rare earth stabilizer, 12 parts of titanium dioxide-attapulgite composite prepared in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com