Ferrocene-based ultrathin metal organic framework nano-sheets and preparation method thereof

An ultra-thin metal, organic framework technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as low yield, uncontrollable nanosheet morphology, and achieve stable chemical properties. , Simple and efficient preparation, simple and efficient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In a 25mL polytetrafluoroethylene liner, add 1,1'-ferrocenedicarboxylic acid (13.7mg, 0.05mmol), zirconium tetrachloride (116.6mg, 0.5mmol) and acetic acid (1.43mL, 25mmol), N,N-Dimethylformamide (15 mL) was added to dissolve it completely. Put the lining into the hydrothermal reaction kettle and react at 120°C for 12h. After the reaction was finished, a precipitate was obtained after centrifugation (3000 rpm, 30 min). The precipitate was washed three times with N,N-dimethylformamide (3x30mL), and then ultrasonically dispersed (30min) with ethanol (30mL) to obtain ferrocene-based ultrathin metal organic framework nanosheets.

Embodiment 2

[0037] In a 25mL polytetrafluoroethylene liner, add 1,1'-ferrocenedicarboxylic acid (137.0mg, 0.5mmol), zirconium tetrachloride (116.6mg, 0.5mmol) and acetic acid (1.43mL, 25mmol), N,N-Dimethylformamide (15 mL) was added to dissolve it completely. Put the lining into the hydrothermal reaction kettle and react at 120°C for 12h. After the reaction was finished, a precipitate was obtained after centrifugation (3000 rpm, 30 min). The precipitate was washed three times with N,N-dimethylformamide (3x30mL), and then ultrasonically dispersed (30min) with ethanol (30mL) to obtain ferrocene-based ultrathin metal organic framework nanosheets.

[0038] The experimental test results are as follows:

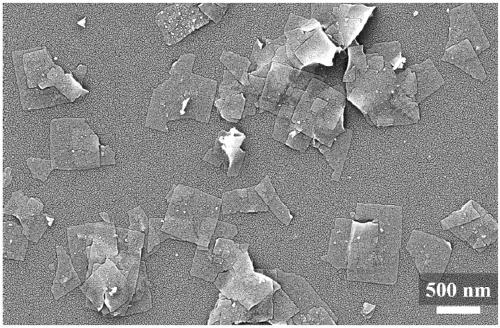

[0039] Such as figure 1 Shown is the scanning electron microscope image of the prepared ultra-thin metal-organic framework nanosheets. It can be seen from the figure that the lateral size of the ultra-thin metal-organic framework nanosheets is about 500nm;

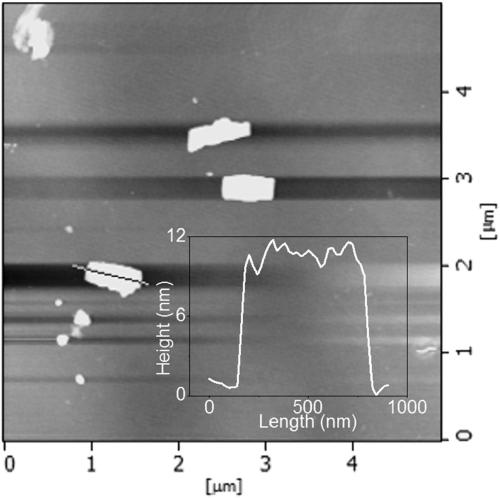

[0040] Such as figure 2 Shown...

Embodiment 3

[0044] In a 25mL polytetrafluoroethylene liner, add 1,1'-ferrocenedicarboxylic acid (685.0mg, 2.5mmol), zirconium tetrachloride (116.6mg, 0.5mmol) and acetic acid (1.43mL, 25mmol), N,N-Dimethylformamide (15 mL) was added to dissolve it completely. Put the lining into the hydrothermal reaction kettle and react at 120°C for 12h. After the reaction was finished, a precipitate was obtained after centrifugation (3000 rpm, 30 min). The precipitate was washed three times with N,N-dimethylformamide (3x30mL), and then ultrasonically dispersed (30min) with ethanol (30mL) to obtain ferrocene-based ultrathin metal organic framework nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com