Connecting rod pin hole fine grinding equipment and crankshaft production process

A production process and connecting rod pin technology, applied in the field of crankshaft processing, can solve the problems of reduced precision, impacted production efficiency, shortened honing time, etc., to improve the use accuracy and life, improve work performance, improve surface hardness and wear resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

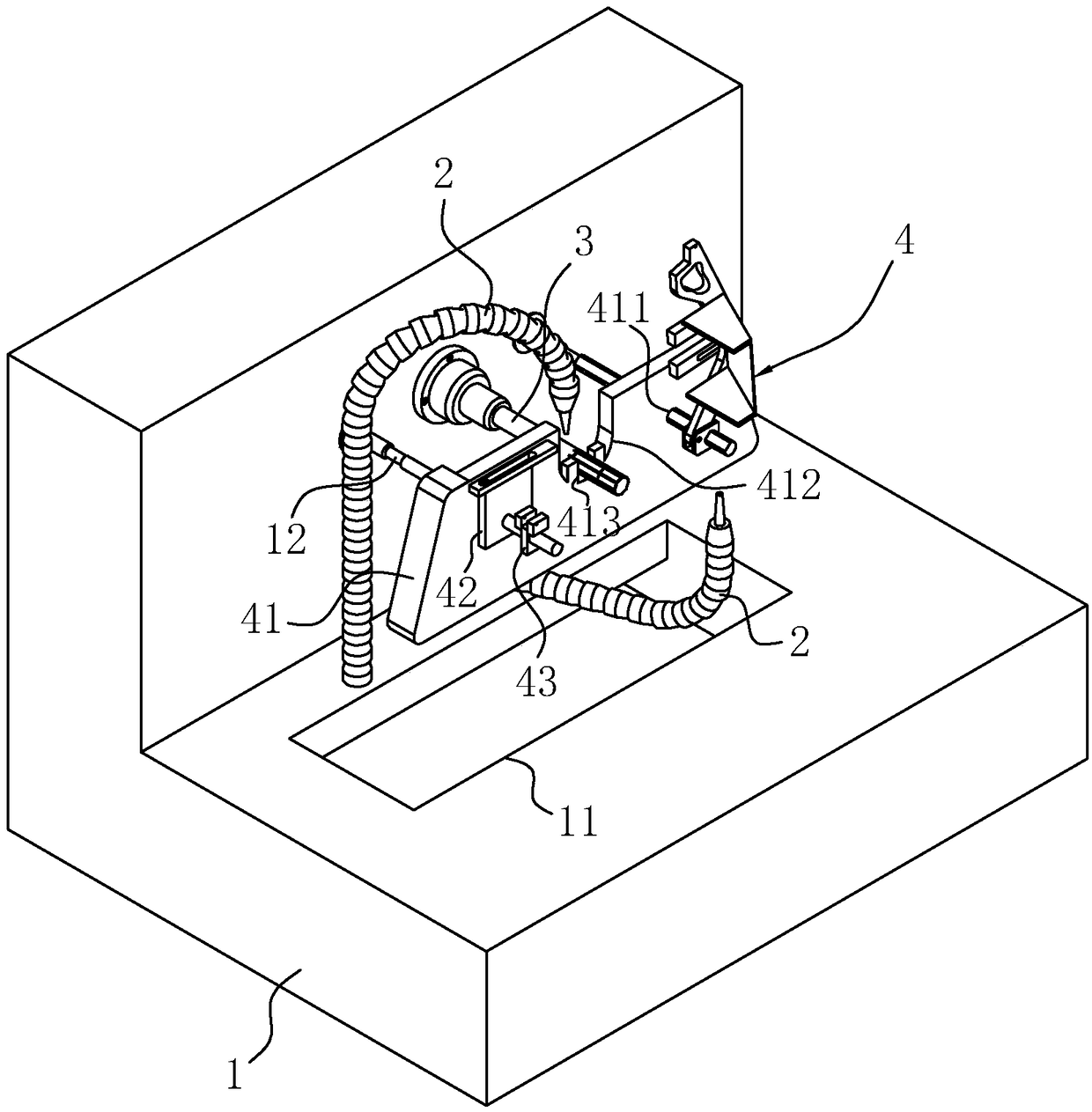

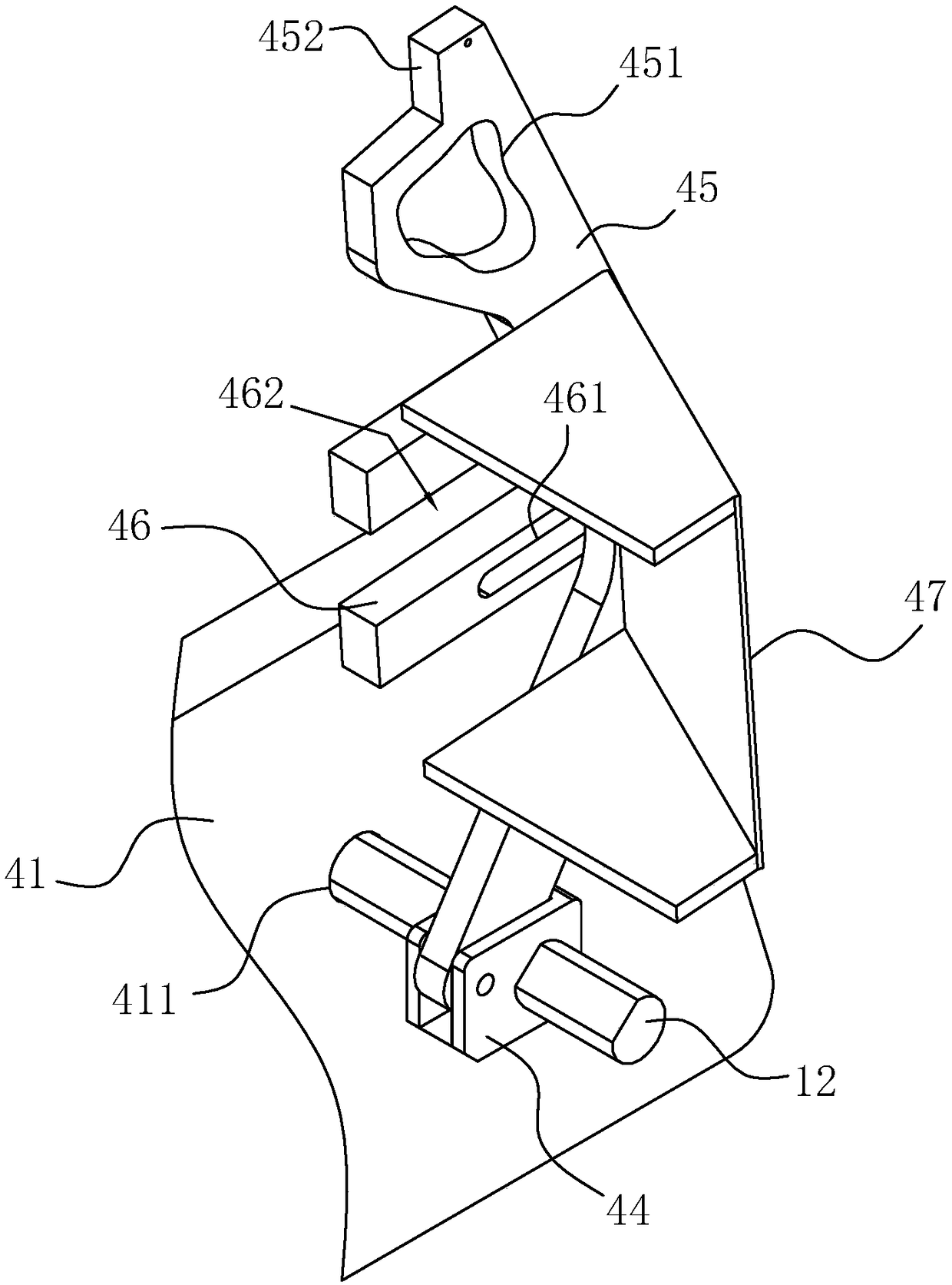

[0050] Embodiment 1: A kind of connecting rod pin hole precision grinding equipment, such as figure 2 As shown, it includes a frame 1 and a grinding shaft 3 mounted on the frame 1 for horizontal rotation. One end of the grinding shaft 3 is connected with a drive motor, and a clamping mechanism 4 is installed on the frame 1 through a support rod 12. The grinding shaft 3 Through the middle part of the clamping mechanism 4, a cooling pipe 2 for spraying cooling fluid to the end of the grinding shaft 3 is installed on the frame 1. Put the pin hole of connecting rod 5 on the grinding shaft 3

[0051] refer to figure 2 , the frame 1 is located below the grinding shaft 3 and is provided with a sump 11, the bottom of the sump 11 is connected to the external coolant barrel through a drain pipe, the coolant barrel is connected to a suction pump through a pipeline, and the suction pump The outlet is connected with the cooling pipe 2. The cooling pipe 2 can use a corrugated pipe, whi...

Embodiment 2

[0066] Embodiment two: a kind of crankshaft production technology, such as Figure 7 shown, including the following steps:

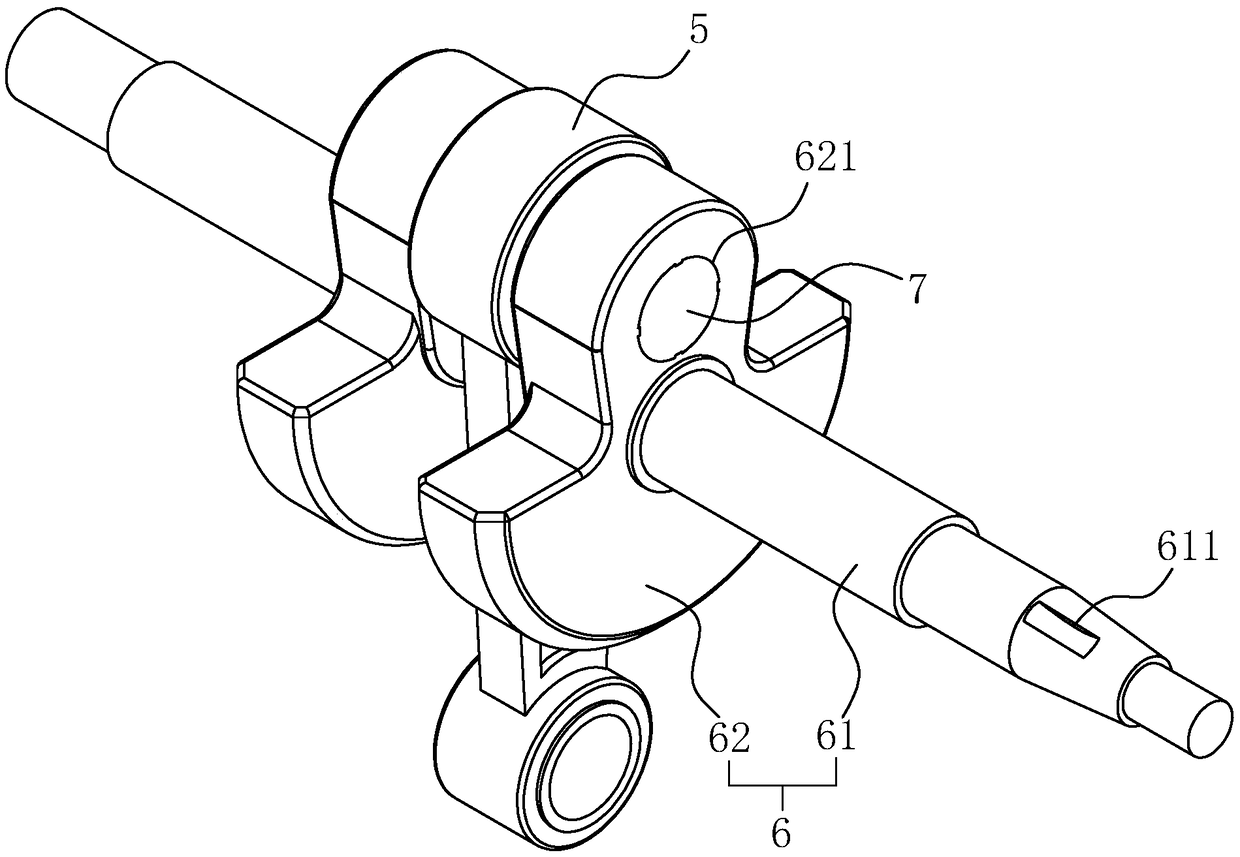

[0067] (1) Crank rough production: heat one end of 20Cr round steel with a diameter of φ20mm and a length of 25cm to 1150°C and upset, so that the round steel becomes a hemispherical blank at one end, and the heated length is 8cm. Then put the preform after upsetting in the forging die and go through the first hot forging and the second hot forging continuously. The temperature of the first hot forging is 1150°C, and the time is 5S; The hemispherical end of the blank is formed into the balance weight 62 of the crank 6 . Then use tools to remove the flash at the balance weight 62, and perform shot blasting on the workpiece to obtain the crank blank.

[0068] (2) Rough machining of the crank blank: fix the balance weight 62 of the crank blank, and process the end face of the round steel far away from the end of the balance weight 62, that is, grind the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com