Numerical control machine tool facilitating separation and collection of waste residues

A CNC machine tool and waste slag technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as ineffective placement of maintenance tools, relative vibration of machine tool housing and base, environmental pollution, etc. Achieve the effects of avoiding environmental pollution and blockage of drainage pipes, improving observation clarity, and scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

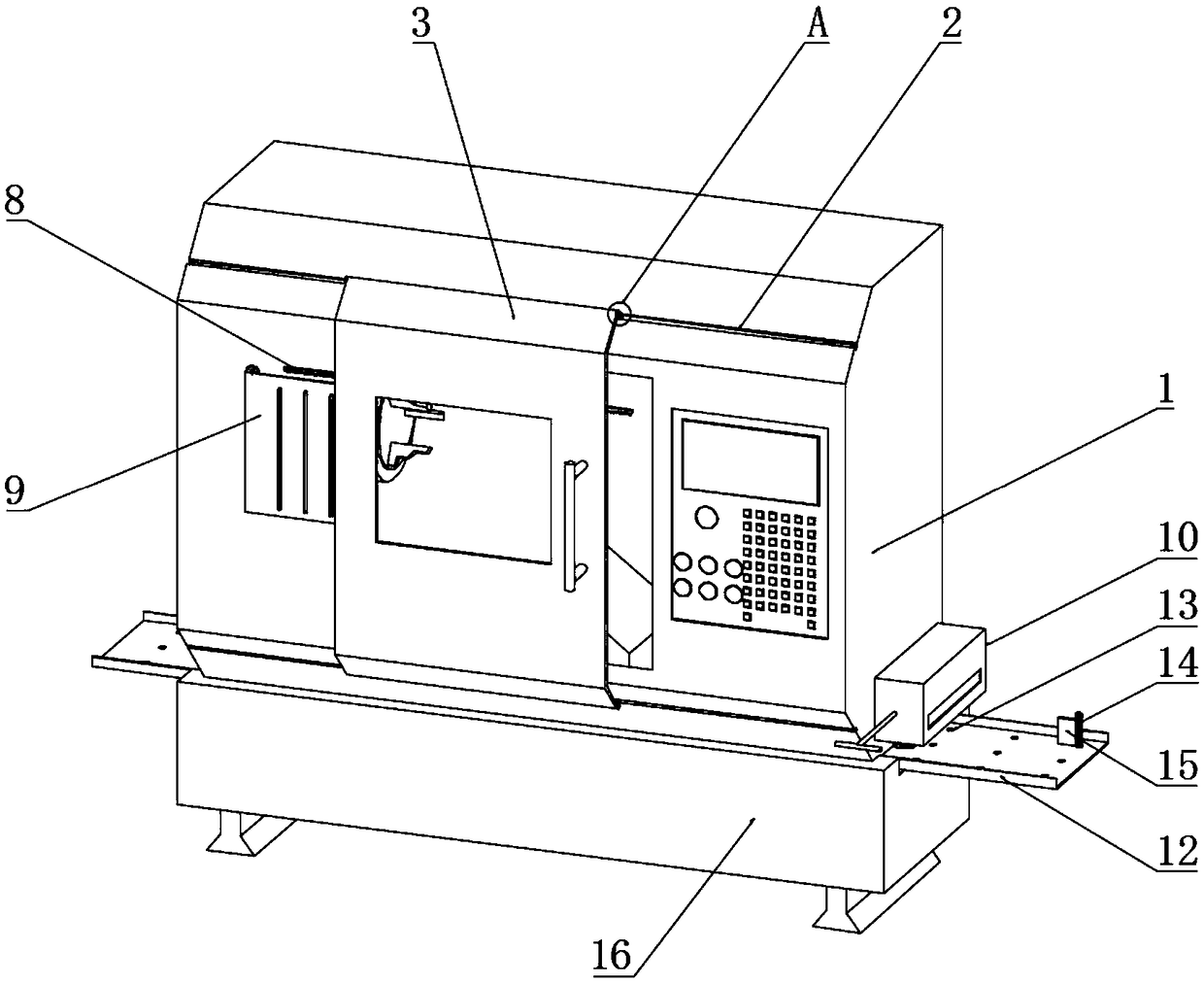

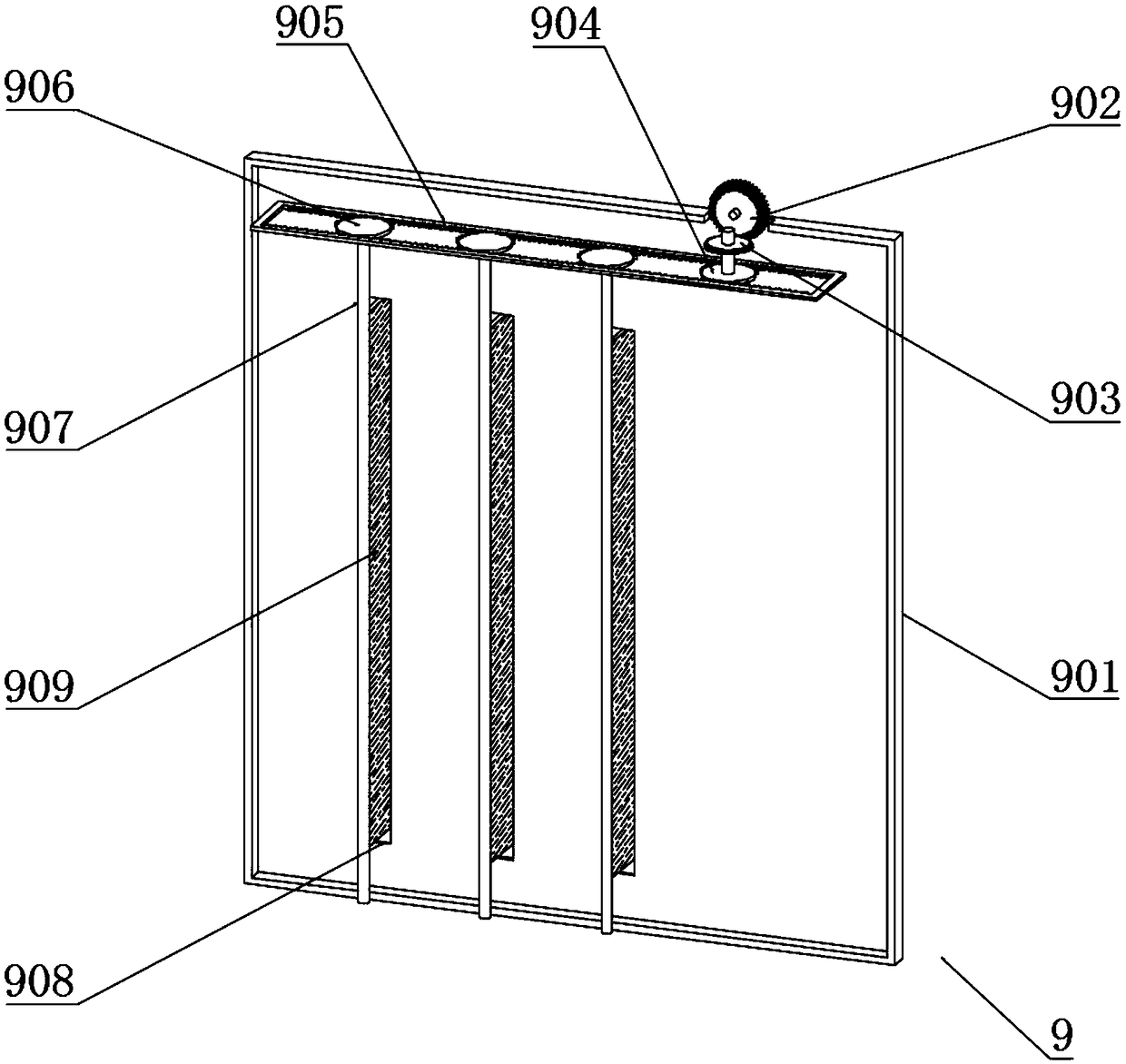

[0029] Example: such as Figure 1-5As shown, the present invention provides a technical solution, a numerically controlled machine tool that is convenient for the separation and collection of waste slag, comprising a fuselage shell 1, the upper and lower parts of one side of the fuselage shell 1 are provided with chute 2, and the fuselage shell 1 A protective door 3 is installed through the chute 2, and both sides of the top and bottom of the protective door 3 are provided with a draw-in slot 4, and a cleaning block 5 is installed on the top and bottom sides of the protective door 3 through the draw-in slot 4, and one side of the cleaning block 5 A clamping block 6 is installed, and a scraper 7 is installed at the bottom end of the other side of the cleaning block 5 .

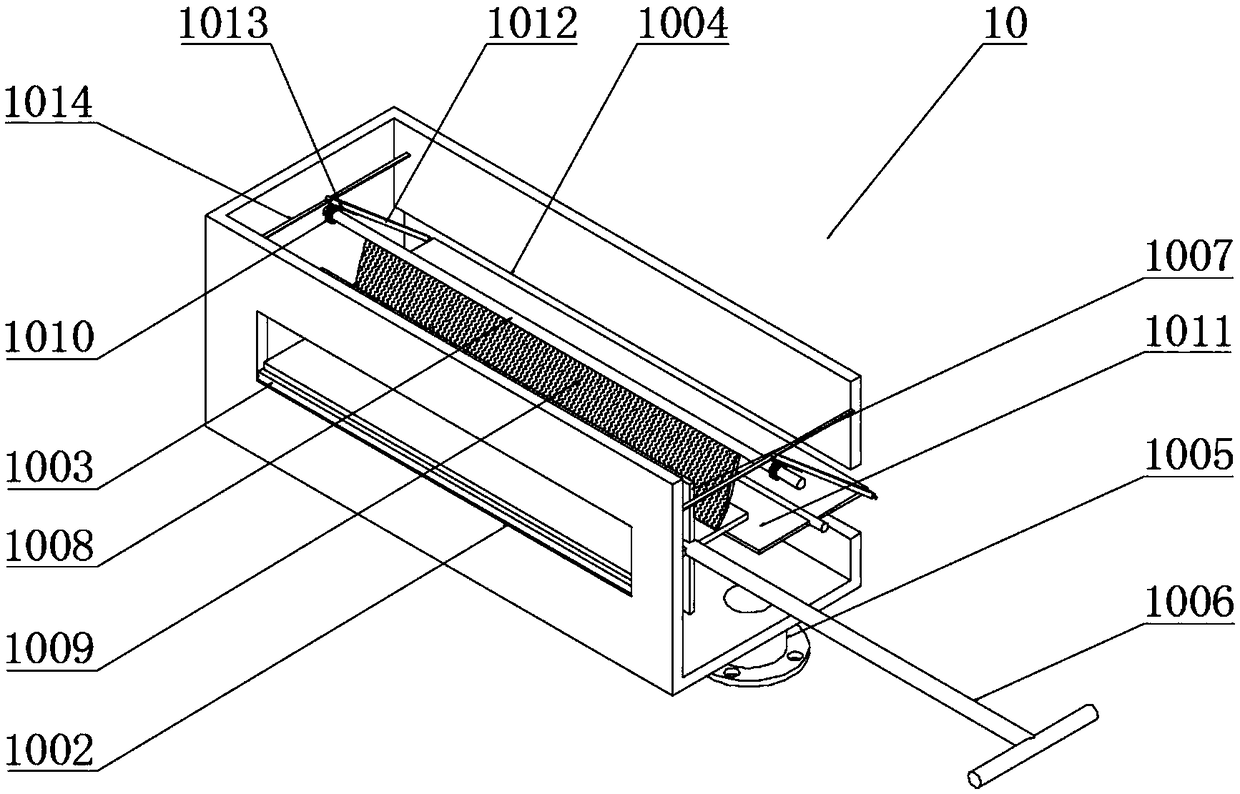

[0030] A waste residue separation mechanism 10 is installed at the bottom of one side of the fuselage shell 1, and the waste residue separation mechanism 10 includes a separation box 1001, a liquid inlet 1002, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com