Sand core manufacturing process and structure of an improved vehicle box

A manufacturing process and an improved technology, which are applied in the field of sand core manufacturing process and structure of an improved vehicle box, can solve the problems of low structural strength and difficulty in exhausting the sand core, achieve good collapsibility, and avoid substandard quality. , the effect of reducing local loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

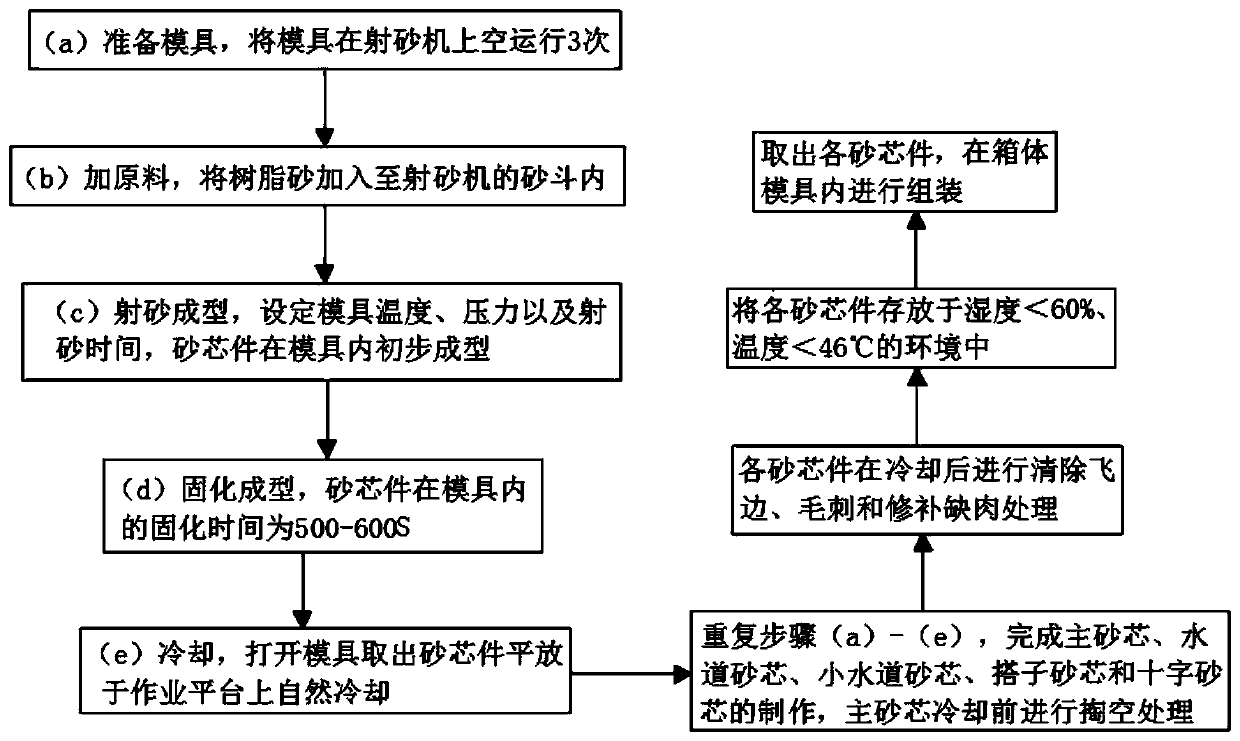

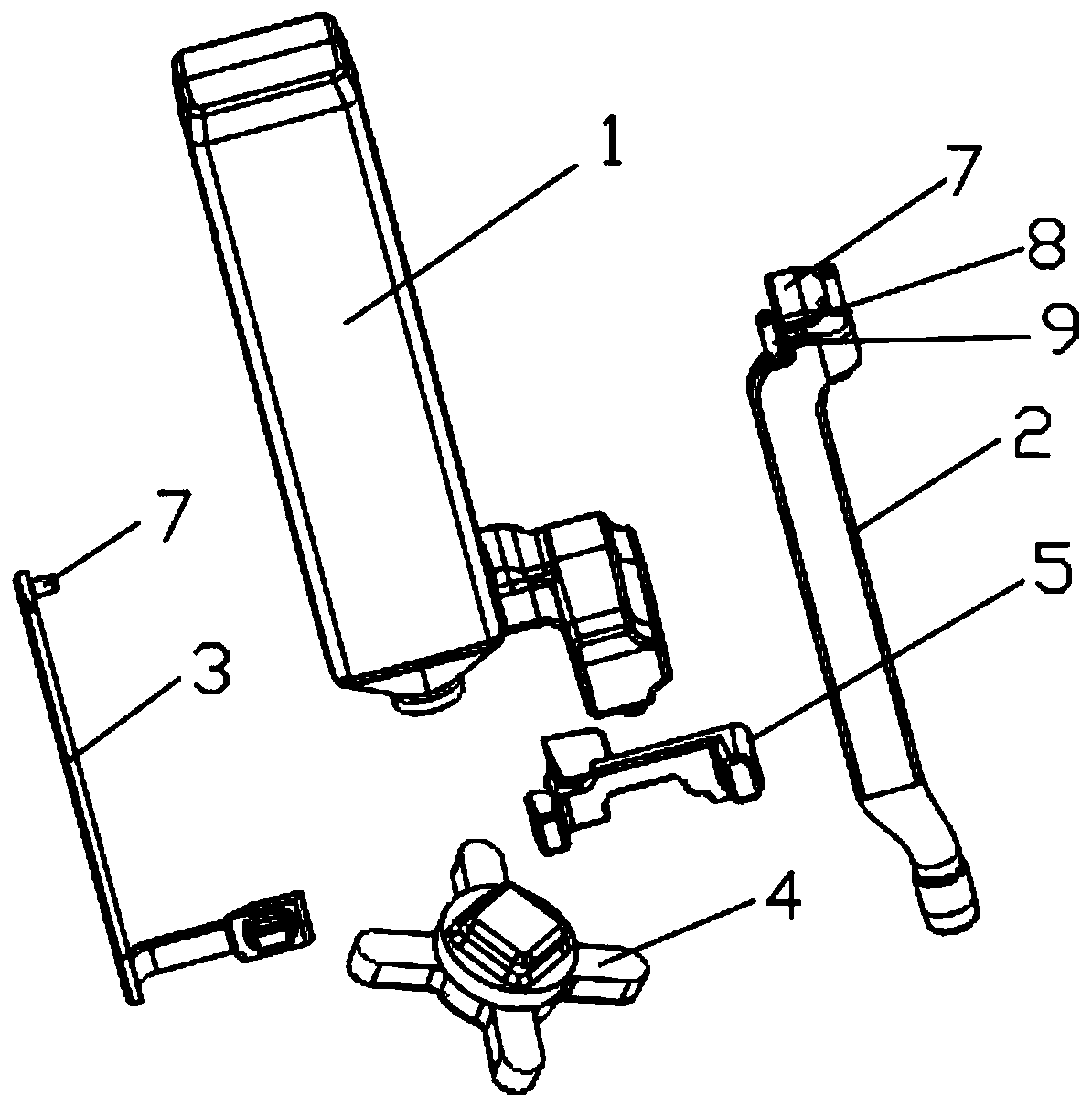

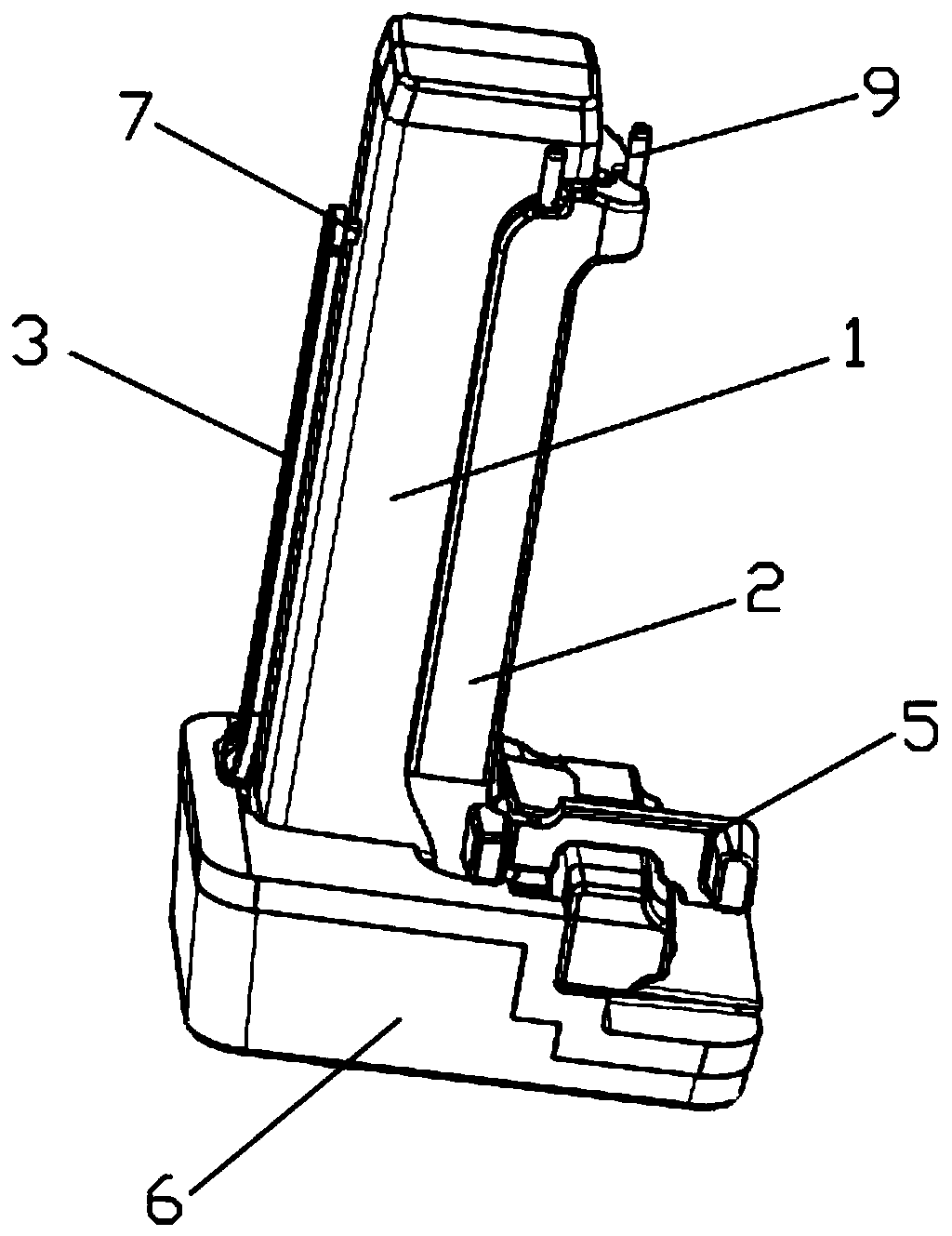

[0039] Please refer to figure 1 As shown, the present invention provides a sand core manufacturing process for an improved car box, including an assembly mold for a main sand core and a water channel sand core, an assembly mold for a small water channel sand core and a lap sand core, and a cross sand core mold, respectively according to Follow these steps:

[0040] (a) Prepare the main sand core and water channel sand core to assemble the mold, (1) After the mold is closed, run it 3 times over the vertical split hot core box sand shooting machine, check, adjust and fasten the mold and equipment bolts, vertical split The type hot core box sand shooting machine is an existing technology, so it will not be repeated here; (2) Clean the mold cavity, clean the residual dirt in the dead corner of the mold cavity, avoid forming obstacles to the filling sand core, and ensure that the sand core is filled. (3) the mold is energized and heated, and a sand core release agent is sprayed in...

Embodiment 2

[0053] Please refer to figure 1 As shown, the present invention provides a sand core manufacturing process for an improved car box, including an assembly mold for a main sand core and a water channel sand core, an assembly mold for a small water channel sand core and a lap sand core, and a cross sand core mold, respectively according to Follow these steps:

[0054] (a) Prepare small channel sand cores and lap sand cores to assemble the mold, (1) After closing the mold, run it 3 times over the vertical parting hot core box sand shooting machine, check, adjust and tighten the mold and equipment bolts, The vertical parting hot core box sand shooting machine is an existing technology, so it will not be repeated here; (2) Clean the mold cavity, clean the residual dirt in the dead corner of the mold cavity, avoid forming obstacles to the filling sand core, and ensure that the sand (3) The mold is energized and heated, and a sand core release agent is sprayed in the cavity of the mo...

Embodiment 3

[0066] Please refer to figure 1 As shown, the present invention provides a sand core manufacturing process for an improved car box, including an assembly mold for a main sand core and a water channel sand core, an assembly mold for a small water channel sand core and a lap sand core, and a cross sand core mold, respectively according to Follow these steps:

[0067](a) Prepare the cross sand core mold, (1) After closing the mold, run it 3 times over the vertical split hot core box sand shooting machine, check, adjust and fasten the mold and equipment bolts, and vertical split hot core box shot The sand machine is an existing technology, so it will not be described in detail here; (2) Clean the mold cavity, clean up the dirt remaining in the dead corners in the mold cavity, avoid forming obstacles to the filling sand core, and ensure the integrity of the sand core filling; (3) The mold is energized to heat up, and in the cavity of the mould, a sand core release agent is sprayed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com