Method for increasing utilization rate of soybean sauce raw materials ultrasonically and catalyzing maturation of flavor

A utilization rate and ultrasonic technology, which is applied in food ultrasonic treatment, food science, etc., can solve the problems of unreported, acceleration, etc., and achieve significant economic benefits, reduced soy sauce precipitation, and low equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

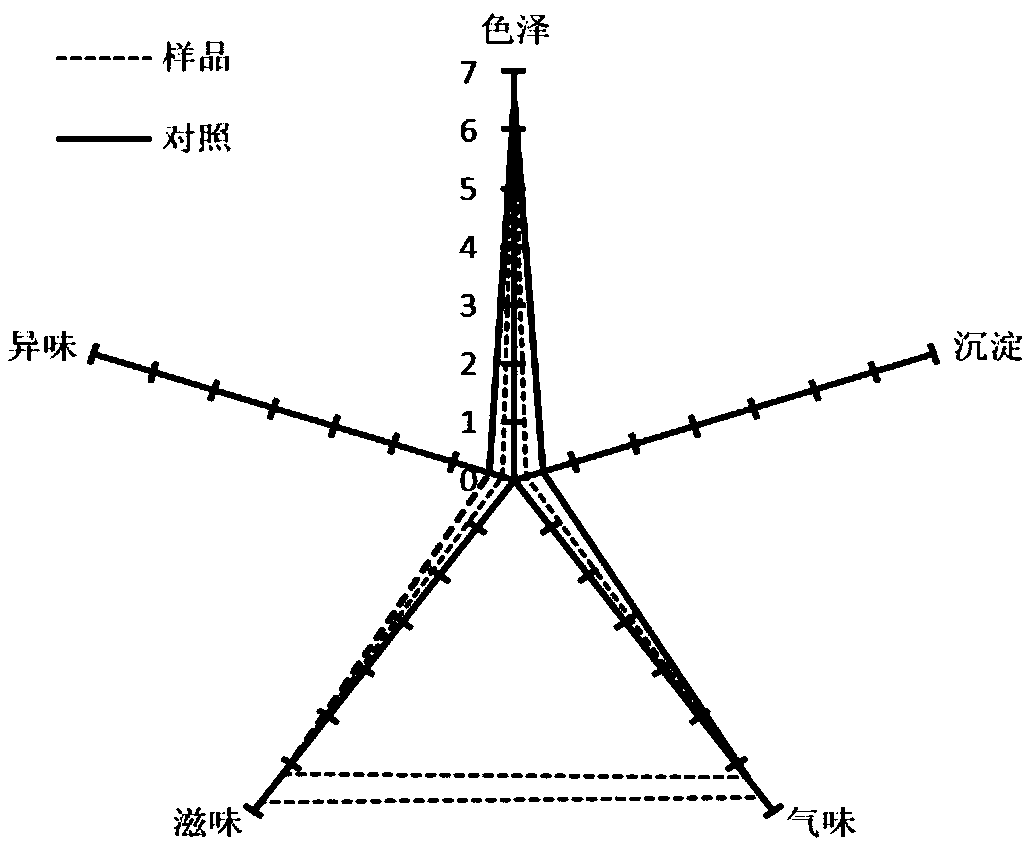

[0021] Embodiment 1 Utilizes ultrasound to improve the raw material utilization rate of high-salt dilute soy sauce (with soybean and flour as main raw materials) and catalyzes the method for its flavor ripening

[0022] The production of high-salt dilute soy sauce uses Aspergillus oryzae 3.042 as the fermentation strain, and the bran is moistened with water (bran: water = 1:0.8), steamed (121°C / 10min), cooled (40°C) , Inoculation (5×10 5 spores / g) at 28° C. and then cultivated in the koji room until the surface is yellow-green (turning the koji twice when the temperature rises to 35° C.), and the prepared bran koji is ready for use. Soybeans are moistened (soybeans: water = 1:1), steamed (121°C / 15min), cooled (40°C), flour and bran koji are pre-mixed and then fully mixed with boiled and cooled soybeans; the amount of flour accounts for 25% of the weight, and the amount of bran seed koji accounts for 0.5% of the weight of Daqu; the inoculated material is cultivated in the koji...

Embodiment 2

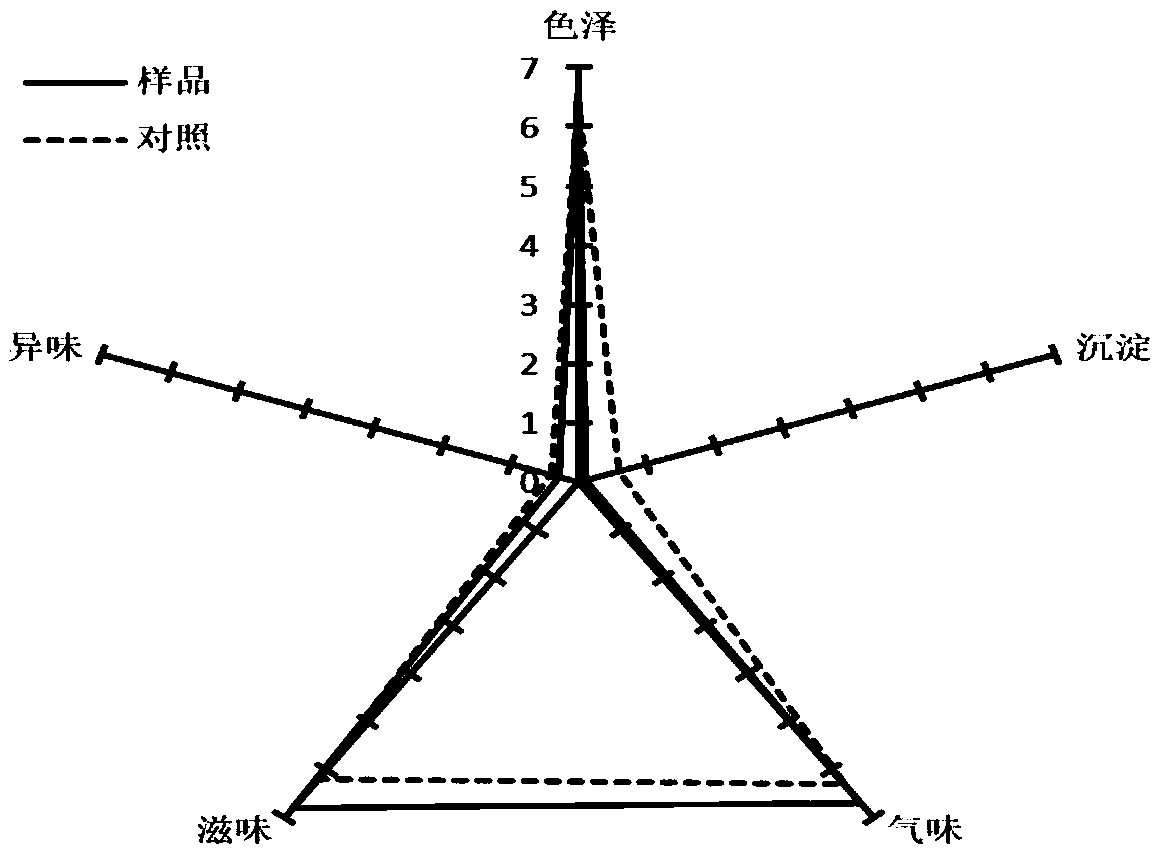

[0024] Example 2 Utilize ultrasound to improve the raw material utilization rate of high-salt dilute soy sauce (with soybean meal and flour as the main raw materials) and catalyze the method for ripening its flavor

[0025] The production of high-salt dilute soy sauce uses Aspergillus sojae as the fermentation strain, and the bran is moistened (bran: water = 1:0.6), steamed (121°C / 10min), cooled (40°C), inoculated (5×10 5 spores / g) at 28° C. and then cultivated in the koji room until the surface is yellow-green (turning the koji twice when the temperature rises to 35° C.), and the prepared bran koji is ready for use. Soybean meal is moistened (soybean meal: water = 1:0.8), then steamed (121°C / 15min), cooled (40°C), wheat is fried and crushed to 2-3 cloves, crushed and cooled wheat is pre-mixed with bran seed koji After that, fully mix with the soybean meal after cooking and cooling; the wheat consumption accounts for 25% of the weight of Daqu, and the amount of bran seed koji...

Embodiment 3

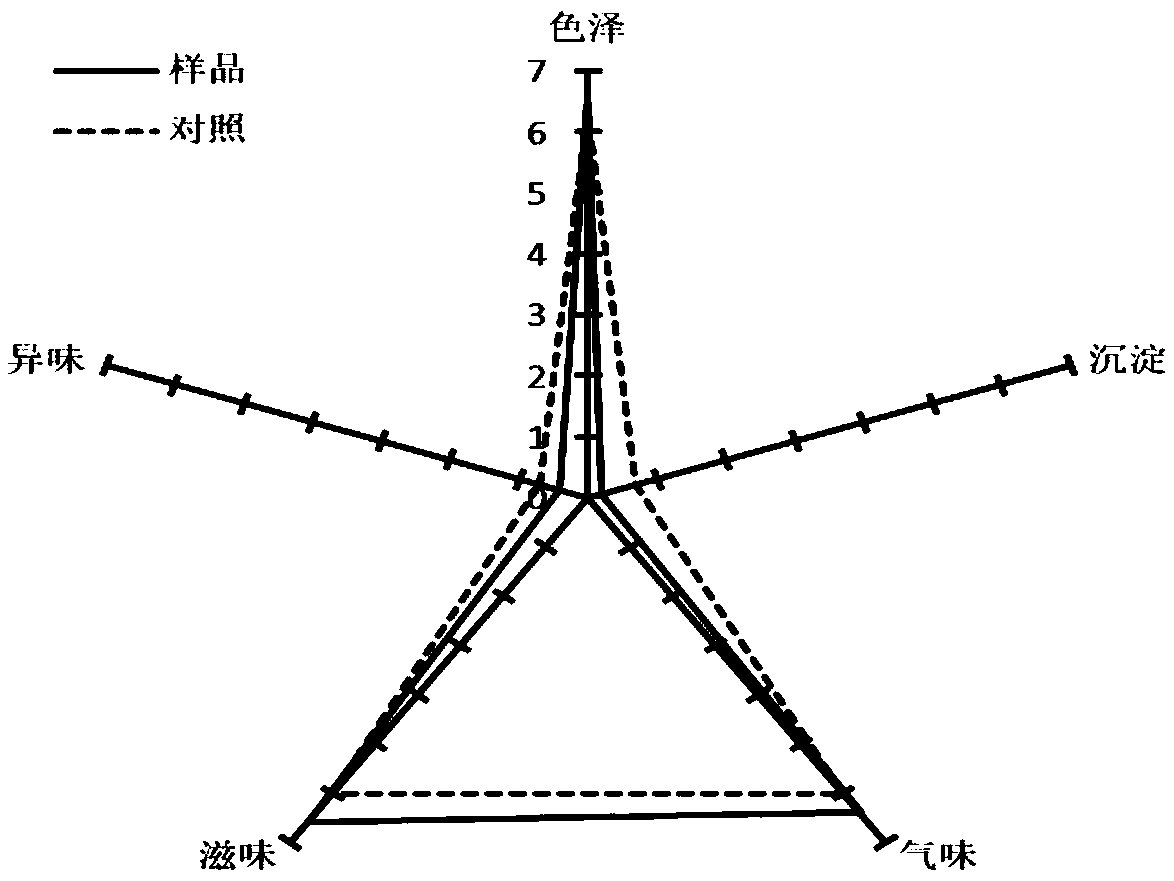

[0027] Example 3 Utilize ultrasound to improve the raw material utilization rate of low-salt solid soy sauce (using soybean meal and bran as main raw materials) and catalyze its flavor maturation method

[0028] The production of low-salt solid soy sauce uses Aspergillus oryzae 3.042 as the fermentation strain, and the bran is moistened with water (bran: water = 1:0.7), steamed (121°C / 10min), cooled (40°C), Inoculation (5×10 5 spores / g) at 28° C. in the koji room until the surface is yellow-green (turning the koji 2 times when the temperature rises to 35° C. during the period), and the prepared bran koji is ready for use. Soybean meal moistening (soybean meal: water = 1:0.8), cooking (121°C / 15min) and cooling (40°C), bran moistening (bran: water = 1:0.7), cooking (121°C / 10min) Cooling (40°C); the cooled bran and bran seed koji are pre-mixed and fully mixed with the cooled soybean meal; the amount of bran accounts for 25% of the weight of Daqu, and the amount of bran seed koji...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com